How to adjust the thread tension in a sewing machine

One of the main criteria for getting a straight and beautiful line when sewing is a properly adjusted thread tension in your sewing machine. Many people mistakenly believe, that it is very difficult to understand in the process of adjusting the tension and try to avoid self-intervention. Actually, getting acquainted with the basic principles of regulation, adjust the optimal level of tension for everyone.

General inspection of the machine

To really be sure, that the string has an unattractive appearance due to improperly adjusted thread tension, you need to check the following.

- The amount of yarn, wound on the upper and lower coil - it must be the same. exept this, pay attention to the correspondence between the thickness of the thread and the needle used. The yarn must not have any damage to the entire surface.

- Serviceability of all working mechanisms. Make sure, that all working mechanisms are well lubricated, and their movements do not have sharp shocks and extraneous sounds.

- Correctness of yarn refueling. This point is especially important in this regard, that many housewives thread their threads incorrectly. Check the filling with the operating instructions, where the only correct way of refueling is indicated.

Check and adjust the tension of the upper thread

The upper thread tension regulator is a rotating mechanism of cylindrical shape, which can be located on top of the case, and on the side.

Detailed information on the location of this mechanism can be found in the operating instructions of the sewing machine.

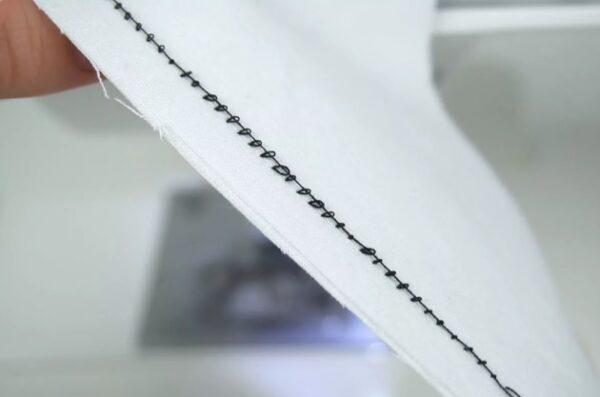

It is worth considering, that it is possible to define optimum level of a tension of a thread by means of trial tailoring of several lines. The situation is an excellent result, at which the line will have an equal and neat look - means, the thread is tensioned correctly. If when sewing lines you noticed, that the string pulls out the plexus with the lower thread on the outer surface of the fabric, means, the tension balance is shifted towards the upper yarn, and it should be weakened. The situation is similar with too little tension - the places of weaving will be visible, but already on the underside of the fabric.

Depending on that, which of the above options characterizes your lines, necessary:

- increase tension;

- reduce tension.

Do not turn the adjuster wheel too sharply. Gradually increase or decrease the degree of tension, until the appearance of the string meets the standard. If for some reason you can not adjust the tension of the upper thread in the sewing machine, go to the next item.

Check and tension of the lower thread

The shuttle mechanism is responsible for the level of tension of the lower thread. For, to determine the optimal tension of the lower yarn, it is necessary to pull out the shuttle and hang it in the air, holding the tip of the thread, coming from the coil. The situation is considered ideal, when the shuttle is lowered no more, than on 2-3 centimeters, and stops the rotation of the spool.

If the shuttle does not fall completely - the thread tension is very large. If it falls very easily, untwisting the spool - then, insufficient tension. This parameter can be adjusted with a special screw.

- Depending on that, do you need to tighten the screw (increase) or untwist (reduce), turn it with a miniature screwdriver clockwise or counterclockwise.

- Take a test run, for, to make sure, that the tension dropped to the optimum level.

- Continue to tighten the adjusting screw until it reaches a smooth and tidy line.

Screw on the shuttle

It is necessary to start adjustment of the bottom thread only after that, how you made the introductory setting of the top. IN 95% cases, when the string has a curved shape, the reason lies in the upper thread.

For a more convenient interpretation of the results when sewing a string, use threads of different colors, which should contrast both with each other, and with the fabric used. This will help you determine exactly, which yarn tension must be adjusted.

General recommendations

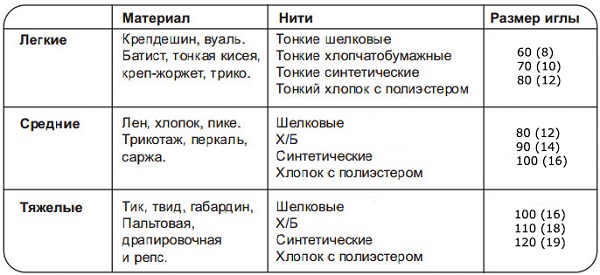

Pay attention to that, that if you use top and bottom threads of different thicknesses, this may require you to make additional tension settings. Ideally, the threads should be from a single spool or, at least, of one type. The mismatch of the size of the needle with the thickness of the thread used can also lead to uneven and crooked stitches.

As well as the thickness of the thread, the set stitch length can significantly affect the quality of the finished product. Too small a size of this parameter can lead to frequent clogging of the tissue under the surface of the needle plate.

Correspondence table of thread and needle

To work successfully with your sewing machine, every housewife needs to know the features of each type of thread.

- Polyester can be considered the most versatile material for making sewing threads. It is very convenient in the process of sewing when solving problems of any complexity.

- Wool yarn is quite thick. It requires a special needle and the appropriate tensile strength.

- A thick needle is needed to work with denim materials, which will not break when stitching.