Press to squeeze the oil with your hands: home production

For the processing of oilseeds special equipment is used - a press for oil extraction. Using such a simple device, which some masters do with their own hands, at home or in small production you can get an environmentally friendly product, which is superior in its taste and usefulness of oil, sold in stores. From that, from which crops and in what quantities it is necessary to obtain oil, depend on the technical characteristics and design of the equipment used.

To get oil for your needs, enough to get the device, the design of which is quite simple

Особливості конструкції саморобного пресу для олії

Obtaining vegetable oil at home using a purchased or self-made press has a number of features, which must be taken into account.

- In the production of oil at home, the finished product has a two-year shelf life. Home press can be purchased in series or made with your own hands.

- With the help of a household press for extraction, you can get oil from sunflower seeds, olives and even nuts.

- One of the simplest and cheapest ways to make a device for oil extraction is the processing of serial household press, designed for squeezing juice from grapes and apples. In such equipment it is not necessary to change working nozzles - it is enough to replace a holder with the device of higher power.. Such modernization will allow to use the unit not only for processing of olives, but also for extracting sunflower oil.

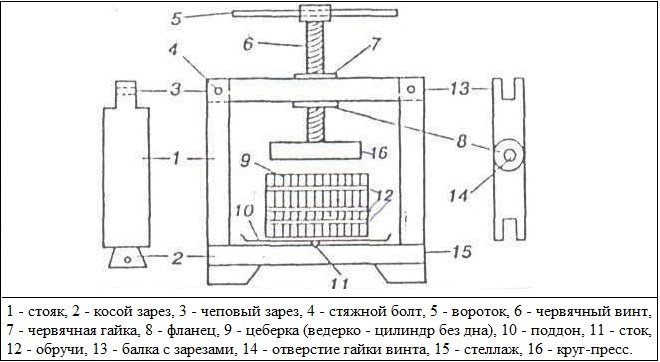

- Home oil press, based on a worm screw, responsible for squeezing, can be made using improvised means. Designing such a press, keep in mind, that pressure, which he will be able to develop, will depend on the diameter of the worm nut, and from the power of the beam risers. To provide the created device with higher reliability, beam, which is the basis of its design, should be made more powerful. These requirements are fully met by a wooden press for oil extraction, elements of the mechanism of which are made of solid oak. A budget alternative to such a unit is the press, structural elements of which are made of metal.

- Household press (like any other), used for oil production, provides for the presence in its design of a cylinder without a bottom, as which you can use an ordinary metal barrel. To increase the rigidity of such a cylinder at its bottom, you can take a metal hoop. If a wooden barrel is used as a cylinder, then the material, of which it is made, must be dry and high hardness. The ideal material in this case would be solid oak.

- To important structural elements, which the oil press must be equipped with, include peeling rollers, representing a pair of replaceable rollers. Their rotation is provided by gears, mounted on metal racks of the device. On the racks, except for gears, fixed upper and lower buckets, as well as the handle, by means of which rotation of elements of the mechanism is provided, or a tipping bucket. Peeling rollers, usually, made of wood, and their working surface is sheathed with a grater cloth.

Worm screw press diagram

Homemade screw press for the production of oil or juice

Principle of action

After a wooden press to squeeze the oil (or metal) assembled and equipped with replaceable nozzles, you can start using it for its intended purpose. To squeeze the oil with such a unit (example, from sunflower seeds), the following steps must be performed:

- Raw materials are filled into the loading bucket of the device.

- Rollers, the surface of which is covered with a grater cloth, rotate with the handle.

- Due to the rotation of the rolls, the raw material is drawn into the gap between them, where the release of the skin occurs (peeling).

- After peeling the sunflower kernels and husks, from which they are exempt, are found in the lower bucket.

- Mixture, consisting of sunflower kernels and husks, Proviyut.

- Rolls with a cloth-grater are replaced by rolls with a smooth surface, by means of which extraction of vegetable oil will be carried out.

- The cleaned seed kernels are placed in the upper bucket and rolled.

- Reduce the gap between the rolls, what is needed for that, so that the seed cores passing between them are compressed with the necessary effort, allows a special lever of the manual press, which translates to the second position.

- The result of rolling is a pasty mass, which must be pressed, to extract vegetable oil from it.

Hand-held wooden hydraulic oil press for squeezing oil from seeds and nuts

Because the manual press for squeezing is not able to provide high pressure, which is done on the raw materials used, the percentage of oil yield is lower, than when using specialized equipment. If you use an electric motor as a drive for such equipment or use a hydraulic press, then you can fix this shortcoming.

Manual oil press has a number of advantages. Here are the most significant of them.

- Due to the simplicity of design, such a press can be made with your own hands.

- The finished product has excellent taste and high nutritional value.

Manual screw press for home oil extraction

It can be used as a wooden one at home or in a small production plant, and auger press to obtain vegetable oil, which are highly efficient. It should be borne in mind: if you do not make such devices for oil extraction yourself, and buy ready-made models, then a wooden press based on a hydraulic mechanism will cost much more, than the screw press. If you take such a unit to organize a small business for the production and sale of environmentally friendly vegetable oil, then it will pay off pretty quickly. Such equipment will pay off even faster, if you use it to produce not only sunflower, but also olive or even cedar oil.

What are the methods of squeezing oil from vegetable raw materials

Vegetable oils, depending on the method of extraction are divided into two main types, each of which involves the use of certain technology and appropriate equipment. Such species, in particular, is:

- oils, obtained by hot wringing;

- cold pressed oils.

Oil production area by hot double pressing

If the oil is produced by hot pressing technology, then porridge, obtained after rolling, placed in special roasters, where it is heated to temperature 110 ° and moisturize at the same time. The mass is constantly stirred. After such preparation, the raw material is placed in an auger device, where pressing is performed, as a result of which oil is allocated. Vegetable oil, obtained by hot wringing technology, differs not only in the beautiful dark golden color, but also a very bright aroma, as well as the taste of roasted seeds.

Meanwhile, cold-pressed vegetable oil is considered more useful, as raw materials for its production are not subject to thermal action, in accordance, the product retains all the useful properties. For cold oil extraction, a similar technology is used, only in it there is no stage of heating passed through the rollers of the pulp. Vegetable oil, obtained by cold pressing technology, although it has more useful qualities, less stored, over time it acquires a darker color and bitter taste.

Production equipment

Even high-performance equipment, designed to produce vegetable oil in industrial conditions, differs in small dimensions, in accordance, does not require much space for installation. Modern models often have mini-complexes for the production of vegetable oil, are equipped with various working modules, which significantly expands their functionality.

Screw oil press, it is intended for cold continuous squeezing as a part of a technological line or as the independent device

So, a typical sunflower oil production line works on the following principle.

- Raw materials must be dried, cleaned of various contaminants, impurities are removed from it.

- In a special module, the seed kernels are separated from the husk and crushed.

- The crushed seed kernels are steamed, and when it comes to hot wringing, then they are roasted.

- Squeezing of oil from the prepared weight is carried out.

- Butter, obtained immediately after squeezing, is the stage of filtration, which significantly increases its purity.

- The finished oil after filtration is poured into a container and sent for storage.

Hot oil production line (click to enlarge)

in addition, Modules are a must in modern seed oil production lines, where the refining and deodorization of the finished product, which increases its quality characteristics.

And finally, a video with a presentation of a professional screw oil press, used in serious production.