Gate pump (plate parts): principle of operation and design

For pumping media, which have the property of becoming more viscous and dense with decreasing temperature, the gate pump is optimally suitable (or, as it is called, plate parts). A design feature of gate pumps, which allows them to ensure a constant degree of viscosity of the medium, pumped, there is a special shirt in their body. Heat carrier, which is fed from the outside and circulates in the inner cavities of such a shirt, the heater is transported through the pump medium, not letting it thicken.

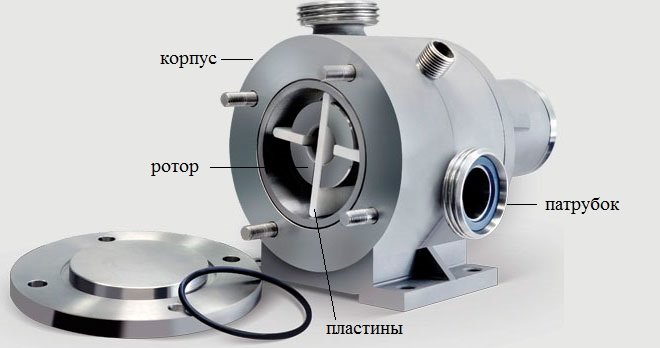

Gate pump for the food industry

Due to the peculiarities of their design, gate-type pumps are successfully used for pumping working media of various types.: pasty, with the content of abrasive particles and insoluble impurities of another type, adhesive mixtures and resins. Pumping devices of this type are characterized by increased suction power, as well as the ability to work with equal effort in two directions.

design features

The design of the gate pump consists of:

- case with two nozzles (suction and discharge), which is made of cast iron or steel alloy;

- drive motor (usually, asynchronous type);

- shaft with plates (rotor), which rotates inside the housing on an eccentric trajectory (the working plates are located in special grooves of the rotor, in addition, grooves are made on the surface of this structural element, having different angles of inclination in those places, where they reach the edges of the shaft).

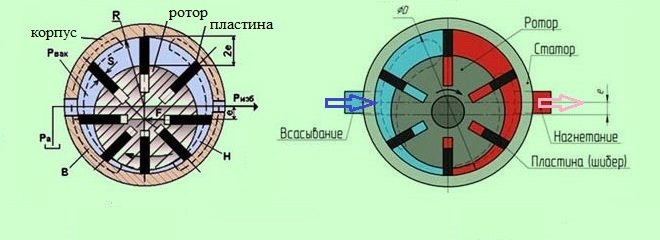

The main parts of the gate pump

Plate pumps fall into two major categories: single and double principle devices. Their main structural difference is in the shape of the cross section of the stator - the element, inside which the rotor rotates.

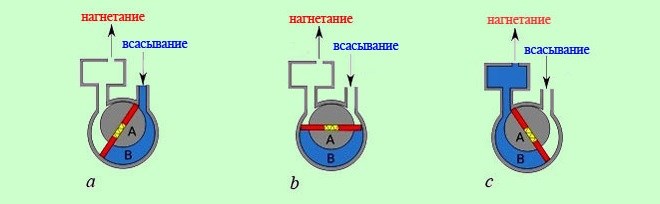

The principle of operation of the plate (or sliding) pumps as single, and double action can be described as follows.

- When rotating the rotor plate, having the ability to move freely in the landing grooves in the radial direction, protrude from them under the action of centrifugal force.

- The end part of the extended plates comes into close contact with the inner walls of the stator and begins to slide on them, moving the pumped device by the medium.

The principle of operation of the gate pump

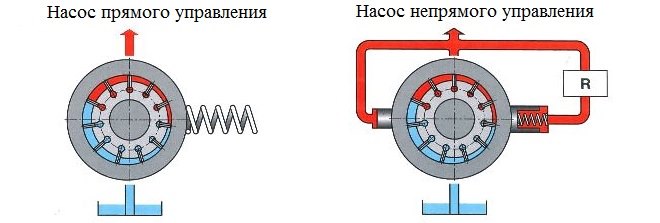

Depending on the scheme, on which control of work of the pump of gate valve is constructed, such a device may relate to adjustable pumps:

- direct management;

- indirect.

Control schemes of adjustable gate pumps

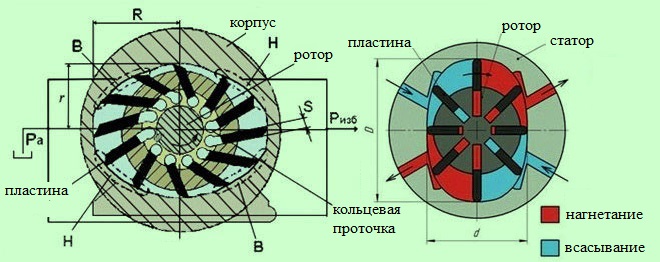

Plate hydraulic machines of double or double action

The main feature of the double-acting gate pump is, that its stator in cross section has an oval shape. Moving on the inner surface of such a stator, each rotor gate makes two strokes per shaft revolution. The double-acting plate pump works according to the following algorithm.

- Temporary working chambers (environment, transported is pumped into them and then displaced into the discharge line) are formed by such elements, as the outer surface of the rotor, oval inner surface of the stator, two adjacent plates and side disks. At the same time temporary working chambers of the smallest volume are created in that place of an internal cavity of the gate pump, where the gap between the rotor and the fixed part of the engine is minimal.

- High tightness of temporary working chambers is provided due to that, that plate, sliding its end part on the inner surface of the stator, tightly pressed against it.

- After passing the plates of the area with a minimum gap between the rotor and the stator, the volume of the temporary working chamber increases. This leads to that, that the pressure drops sharply in it, so, the area of rarefaction of air is created. When passing the inner surface of the stator, where the side disk is located, slots in which are connected to the suction line, the temporary chamber is filled with the pumped medium.

- When a temporary working chamber, already filled with liquid, pumped, passes the next section with a minimum gap between the rotor and the stator, it increases the pressure of the working environment, which contributes to the displacement of the latter in the slot of the second side disk, connected to the discharge line.

- So, due to the oval shape of the stator cross section, the above process for one revolution of the rotor shaft occurs twice.

The principle of operation of the double-acting plate pump

Due to the pressure of the end part of the working plates to the inner surface of the stator when they slide on it is affected by the fluid pressure, which is done on the back surface of such elements. Calculate the effort, with which the plates in the sliding process are pressed against the inner surface of the stator, it is possible, if you multiply the fluid pressure, affecting the rear surface of such elements, on the area of their end part. When pumping liquids under a certain pressure, characterized by poor lubricating properties, situations may arise, when a thin film of the working medium will be formed between the end surface of the plates and the inner walls of the stator. Operation of the plate-type pump in such conditions promotes intensive wear of its working elements.

If the vane pump is to be used for pumping liquid, which enters the suction pipe under pressure, exceeding 150 there is, then to solve such problems choose models of pumping devices, the design of which is completed with double plates. The pumped liquid in such cases is fed through a hole in the rear end of the gate pump and enters the space between the paired plates, which allows you to compensate for too much fluid pressure, which is done on the blades.

Single action devices

Cross section of the rotor of the gate pumps, working on the principle of single action, has a cylindrical shape. Changing the volume of the temporary working chamber (this is a necessary condition for the efficient operation of plate-type pumping equipment) provided by, that the rotor relative to the stationary part of the engine performs rotational movements along the eccentric trajectory.

The principle of operation of single and double-acting gate pumps, despite differences in their design, the same.

The principle of operation of a single-type gate valve

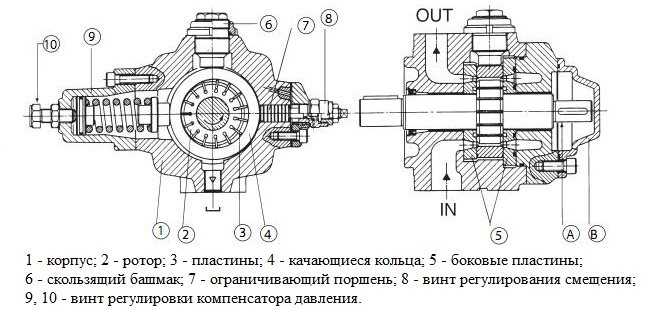

Hydraulic machines of adjustable type

In adjustable gate pumps, the position of the stator ring can be changed. Adjusting the spatial position of the stator relative to the rotating rotor inside it, to perform which in the design of the pump there are three screws, carried out as follows.

- You can change the eccentric path with the feed restriction screw, on which the rotor moves. Due to this, the supply level of the gate pump is regulated.

- With the help of the screw adjusting the position of the support, you can change the spatial position of the stator in the vertical plane. The dynamic characteristics of the pump and the noise level depend on this parameter, which he issues at work.

- The screw of adjustment of the maximum pressure allows to control this parameter due to change of degree of compression of a special spring.

Device of the sliding pump with adjustable working volume

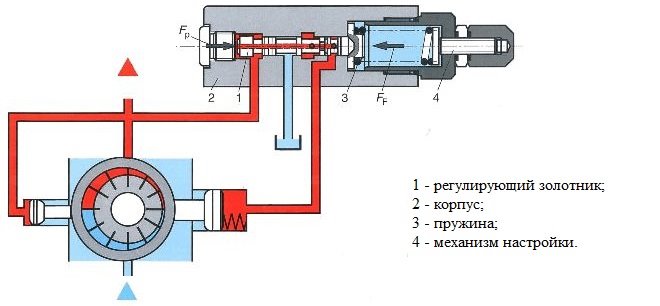

The principle of operation of the gate (plate of frequent) the pump of adjustable type consists in the following.

- The pressure is pumped, depending on the resistance of the fluid in the hydraulic system, affects the inner walls of the stator, and through them - on the adjusting spring. While the value of this pressure is less, than the force of spring resistance, the winding ring is in the eccentricity relative to the rotor.

- As the pressure of the working medium increases in the hydraulic system, the degree of its influence on the walls of the fixed part of the engine and the adjusting spring also increases.

- At that moment, when the fluid pressure exceeds the spring back pressure, the winding ring will begin to move from the eccentricity to the concentric position. At the same time there is a decrease in the volume of temporary working chambers of the gate pump, and, in accordance, fluid pressure decreases, which he feeds into the discharge line. During a further increase in fluid pressure, entering the suction pipe, the pressure of the working medium in the discharge line can approach zero (zero stroke of the pump). However, even in this situation, the pump will supply liquid, pumped into the discharge line, the volume of which will be equal to the value of the internal leaks of the device. The magnitude of the fluid pressure in the line, giving, in which the above situation becomes possible, varies by the degree of compression of the adjusting spring.

The principle of operation of the pressure regulator

Equipped with adjustable gate pumps, in which the option of zero course is provided, enter the drainage system. Through it, all internal leaks are removed from the high pressure zone of the working chamber of the device. The presence of such a system in the design of the gate pump allows you to effectively dissipate heat from the friction elements of the device, and also provides their lubrication.

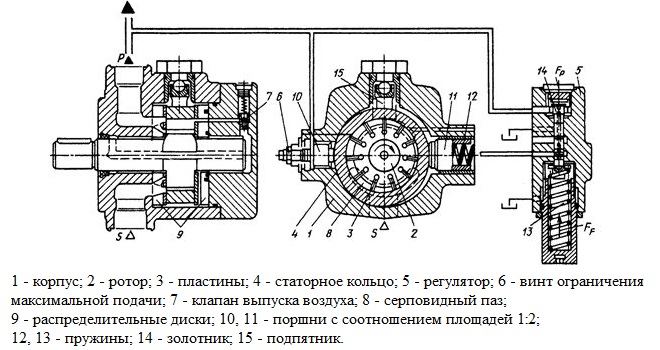

Adjustable plate pumps of indirect action

The very principle of operation of adjustable shut-off pumps of indirect action is almost indistinguishable from the method of operation of devices with direct control. The main difference is in the types of control mechanisms used. If in sliding pumps with direct regulation such mechanism is a spring or two springs at the same time, then in adjustable pump devices of indirect type pistons are used for these purposes, which, being under a certain pressure, provide the required spatial position of the stator.

Device of the adjustable plate pump of indirect action

In the design of adjustable pumps of indirect principle of operation, usually, two pistons are used simultaneously, whose diameters are correlated with each other in proportion 2: 1. The principle of operation of sliding (plate parts) pumps of this type is as follows.

- The limiting eccentricity of the stator at the time of starting the gate pump is provided by a control spring, which in turn affects the piston of larger diameter.

- Fluid pressure, coming to the pump on the suction line, affects both the piston of smaller diameter, and on the big piston, for which a special regulator is used.

- While the value of fluid pressures, affecting both pistons, levels, the stator is at the point of maximum possible eccentricity, provided by the difference in the diameters of the pistons, with which it is associated. When the pressure changes to a greater or lesser extent, the position of the stator relative to the rotor of the gate pump automatically begins to change..