White smoke from the exhaust pipe of a diesel engine

Analysis of the color of the exhaust gases of a diesel engine is one way to control the normal operation of the power unit. The condition of the engine can be assessed with great accuracy by the color of the diesel exhaust, to localize faults of systems and structural units of the engine, to detect the wear of CNG, Timing, failures of diesel injectors, TNVD, etc..

Diesel engine smoke is the product of combustion of the working mixture in the form of gas. The optimally tuned diesel engine with serviceable systems does not smoke after warming up, emissions into the atmosphere are visually visible only in the cold season and are white water vapor. The change in the color of the exhaust gases of the diesel engine indicates a number of certain faults of the internal combustion engine. In various cases, diesel exhaust often occurs:

- white (with a tinge of gray);

- you (grayish-blue);

- thick black (smoke with soot);

We also recommend reading the article about it, why the diesel engine smokes black smoke. In this article you will learn about the causes of black diesel exhaust, ways to detect faults in individual components and systems of internal combustion engines.

Diesel smokes white exhaust

Fuel injection of a diesel unit means the supply of fuel to the cylinders under high pressure through a diesel injector. At the moment of passing of diesel fuel through a nozzle the so-called torch of a saw is formed, thanks to which the supplied fuel is evenly divided in the diesel cylinder into small drops. Next, the dispersed fuel particles inside the cylinder are heated, their active evaporation begins.

Fully stroke four-stroke diesel engine in any mode (at idle or under load) unit receives an efficiently dispersed portion of fuel at a clearly defined time after the compression stroke in the engine cylinder. Next is the spontaneous combustion of the mixture from heating. After the fuel-air working mixture of diesel fuel and air burns fully, giving the maximum useful energy of the piston. The result is the release of exhaust gases from the cylinder. White smoke from the pipe of a diesel engine occurs for the following reasons:

- high humidity in the exhaust system on heating;

- the fuel may not burn completely in the diesel cylinders;

- ingress of coolant into the cylinders of the internal combustion engine;

Condensate in the exhaust system

For a cold engine warm-up mode, a white diesel exhaust is normal. Actually, white color is given by water vapor in the exhaust system of the car. Water condenses from the air after the machine is idle. Some of the condensate after starting the engine flows in the form of water droplets and collects at the end of the exhaust pipe, and the rest of the water begins to evaporate. After heating the exhaust system of a diesel or gasoline engine, water and condensed steam usually disappear. The exception is the winter period. The lower the temperature outside, the longer and more intense is the vaporization. The reason - the exhaust system heats up in the cold much slower.

Diesel fuel does not burn completely

Also, the white exhaust during the heating of the diesel engine is due to untimely spontaneous combustion of the working mixture in the cylinder. The whitish-gray color of the exhaust indicates the presence of gases, which had to push the piston into the cylinder, and found themselves in the exhaust.

Note, that this phenomenon is characteristic of a working diesel engine in the process of warming up in winter, and faulty diesel. In the first case, diesel fuel enters the cylinder, evaporates, but complete combustion of the mixture does not occur taking into account the fixed angle of fuel supply. This is due to insufficient temperature inside the cylinder for timely ignition, which passes immediately with the heating of the internal combustion engine and does not indicate a malfunction.

The appearance of a white exhaust with a grayish tinge on a fully heated diesel indicates a deviation from the norm. The reason is the same delay of spontaneous combustion of fuel in the combustion chamber as a result of the broken angle of supply of fuel, but this occurs after the motor reaches operating temperature.

If the diesel smokes white, it says so, that diesel injectors normally feed and spray diesel fuel. Delaying the flash leads to a decrease in temperature in the cylinder, the rate and uniformity of combustion of the mixture decreases, and regardless of the efficiency of the fuel spray nozzle. In this case, the white color of the exhaust of the diesel engine indicates:

- problems with voltage spark plugs;

- drop in compression in the cylinders;

- wear of plunger pairs of pump;

- high injector injection pressure;

We also recommend reading the article about the device of the diesel engine power supply system. In this article you will learn about design features, components and features of operation of the diesel engine fuel system.

Coolant in the cylinders

The presence of very thick white smoke in the exhaust of the heated diesel engine can be caused by the ingress of coolant into the engine cylinders from the cooling system of the power unit.. Exhaust color may vary, as the presence of antifreeze or antifreeze in the combustion chamber causes the diesel to smoke white, gray or white - bluish smoke. It depends on the components, which are a part of coolant in cooling system. The density of smoke is also affected by the outside air temperature (with negative indicators, the exhaust becomes thicker).

The main cause of diesel smoke in this case is water, contained in the coolant. It actively evaporates from contact with heated nodes. The result is abundant fog from the exhaust pipe. This fault is especially dangerous for a diesel engine compared to a petrol car. The sulfur content in diesel fuel is increased, high temperature in the cylinder, and the ingress of water from the coolant leads to the active formation of sulfur oxide. The presence of sulfur dioxide has a detrimental effect on the life of the diesel engine and associated systems.

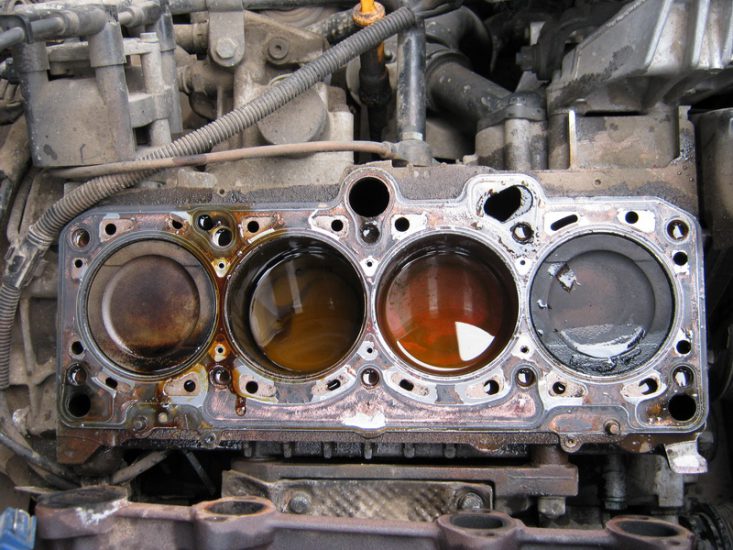

Coolant will get into the cylinders as a result, that can be pierced, deformed or burnt cylinder block gasket (BC). Also a common cause is a crack in the cylinder head (GBC) or in the cylinder block itself. The liquid can also enter the internal combustion cylinder through the intake system. This is caused by a leaky intake manifold gasket, if on the concrete motor it is possible constructively.

Additionally, the penetration of fluid into the cylinders can be diagnosed by monitoring the condition of the cooling system, coolant level checks, as well as the presence of exhaust gases (gas plugs) in the engine cooling system. For this purpose it is enough to unscrew a stopper of a radiator or an expansion tank. The smell of exhaust gases and / or an oil film on the coolant surface will indicate the diagnosis. The level of liquid when entering the cylinders will naturally decrease. If the cold engine start, while not twisting the plugs of the expansion tank, then the pressure in the cooling system will increase, the coolant level in the expansion tank will rise, but will be unstable. Gas bubbles will also appear in the tank, Coolant can be sprayed from the filler neck of the tank.

If the engine is shut down, the liquid from the cooling system will start to enter the cylinder, will pass through the piston rings and ??will be found in engine oil. So antifreeze gets into the crankcase pan. Gradually mix the oil with the coolant. The result will be an emulsion. It is the engine oil from contact with the liquid visually brightens and loses luster. Useful properties of the oil are lost. Penetration of the emulsion into the lubrication system will cause the appearance of a characteristic light brown-yellow foam. The specified foam will be deposited on the valve cover and the plug of the oil filler neck.

Small microcracks mean, that in the cooling system there may be no signs of gases and oils. The amount of coolant in the engine oil for such damage is not large, the oil may look clean, the foaming process under the valve cover plug is present, but it is not intense.

More serious damage leads to the active accumulation of coolant in the piston space, which complicates the start of the engine (heavy rotation of the crankshaft starter). Excessive coolant leaks into the cylinder can result in water hammer, bent connecting rods and overhaul.

Must be added, that such problems are often associated with preheating of the diesel engine. In parallel with the elimination of the main problem, the cooling system may also require careful inspection. It is necessary to make sure that the thermostat is working, radiator, radiator plugs and expansion tank, cooling fan, serviceability of the sensor of inclusion of the fan, the integrity of the pipes and the reliability of the connections.

Conclusion

The presence of white smoke, except for cold condensate, in the exhaust of the diesel engine indicates a malfunction of the engine. In the latter case, the need for urgent repair of the diesel engine is obvious. If you notice signs of coolant getting into the cylinders or other symptoms described above, then further operation of the faulty engine is strictly prohibited. The problem can get worse quickly because of that, that the emulsion in the oil significantly increases the wear as a cylinder-piston group (CPG), and other systems and components of a diesel or gasoline engine.