Aluminum electrodes - welding features, Photo, video

Aluminum electrodes are very convenient to use. With their help, you can quite easily perform welding of parts, made of aluminum alloys. It became possible to carry out such technological operations, that the use of such electrodes allows to destroy a strong oxide film, which covers the surface of products made of aluminum and its alloys.

Aluminum rods for welding

Welding of aluminum

The presence of such electrodes is not the only condition, which must be performed, to obtain a high-quality welded connection of parts, made of this most common metal. First of all, to cook such products, it is necessary to thoroughly clean the surfaces of dirt and oxides, and also prepare their edges: give them the optimal profile.

Organic solvents are used to clean aluminum parts and remove grease from their surface, and in production conditions, alkaline baths are used for this purpose. Of the most common solvents, which are used for this, you can select "White Spirit", technical acetone, warehouses "RS-1" and "RS-2". Such solvents are easy to purchase at specialized sales points.

If there is a need to use an alkaline bath, then you can prepare it with your own hands at home. To do this, you need to mix the following components:

- 1000 ml of water;

- 50 g of soda ash;

- 50 p of technical trisodium phosphate;

- 30 g of liquid glass.

Electrodes for manual aluminum welding Kjellberg Finsterwalde CMA 512

In order to process an aluminum part, the resulting composition must be preheated to temperature 65 degrees. The exposure time of the aluminum product in such a solution is also important, which makes 5 minutes.

The next operation, which must be performed, is the cleaning of aluminum from the oxide film. This procedure is performed using special brushes, the bristles of which consist of thin (diameter up to 0,1 mm) steel wire. After cleaning with such a brush, the aluminum surface must be treated with a solvent once again, to degrease.

Electrodes for aluminum welding also require preliminary preparation. So that the welded joint turns out to be of better quality, experts recommend drying the electrodes before use at a temperature 200 degrees, for which special ovens are used. Such drying must be carried out during 2 hours. After performing all the above procedures, you can start cooking aluminum parts, for which an ordinary inverter can be used.

The principle of welding with a tungsten electrode in a shielding gas environment

The following welding modes are selected: direct current, i.e. with reverse polarity, the strength of which should be 25-30 amperes per millimeter of electrode diameter, which is used. If there are higher requirements for the quality and reliability of the received connection, then the parts are best preheated to 250-400 degrees. Importantly, that the greater the thickness of the aluminum parts, they must be heated to a higher temperature.

Aluminum parts are heated before welding for that, to ensure good meltability of the joint zone and, in accordance, good seam quality. To minimize the risk of distortion of aluminum parts after welding and to avoid crystallization defects of the finished joint, it is necessary to ensure their slow cooling after the end of the process.

If large-sized parts are expected to be cooked, then they are not heated completely, but only those areas, which are in the zone of the future welded joint. When the welding of the aluminum parts is complete, the following technological operations are performed:

- the weld is cleaned of crust, that formed slag;

- before it has cooled down, the seam is poured with hot water;

- the seam is processed using a brush with metal bristles.

Welding seam using OZANA-2 electrodes

Methods of welding aluminum

Boil the details, made of aluminum and its alloys, can be done in different ways. The most common of them are the following.

Manual welding using an electric arc

Metal or coal rods can be used as electrodes when performing such welding, which ensure the burning of the electric arc, heating and melting of the edges of the connecting parts. Due to the introduction of aluminum wire into the welding zone, the surface of which is covered with a special flux, seam formation is ensured. With the help of such arc welding, it is possible to connect parts of small thickness, and also eliminate small marriage in aluminum castings.

Automatic electric arc welding, which is performed using special equipment

Aluminum parts can be butt-welded using this method, whose thickness exceeds 4 mm. To obtain a connection by this method, melting electrodes and current with reverse polarity are used. The formation of the weld takes place under a layer of special flux, which is pre-kneaded, grind through a sieve and roast at a temperature 300 degrees.

Modes of argon arc welding of aluminum with a tungsten electrode

Welding, carried out in the environment of helium and argon gases, which perform a protective function

Such a technological process, in which arc discharge is also used, is performed using melts, made of tungsten. Thanks to the use of shielding gas, the arc during such welding is characterized by exceptional combustion stability, therefore, this technology can be used to connect even very thin parts. To cook in this way, automatic or manual devices can be used. In the first case, welding wire is used, which is automatically supplied to the welding zone, in the second, the electrodes for forming an arc and the additive material made of aluminum do not melt. Welding using this technology can also be performed on three-phase current, for this, a submersible and pulsed arc should be used.

Aluminum welding, in which a plasma arc is used, powered by alternating current

In devices, working on this technology, tungsten electrodes are used (diameter 0.8–1.5 mm), and arc protection is provided by helium or nitrogen.

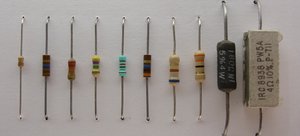

Types of electrodes

For welding aluminum, as well as alloys based on it, several types of electrodes are used. In particular, they include the following.

Alkaline-salt group electrodes (OK: 96.10, 96.20, 96.50)

It is best to use such electrodes, to cook alloys, the basis of which is aluminum, magnesium and manganese, as well as technical aluminum parts. Such electrodes are very critical to storage conditions due to high hygroscopicity, therefore, they need reliable protection from high humidity.

Electrodes are OK 96.20

Aluminum electrodes of the popular "OZANA" brand

There are two modifications of electrodes of this brand, one of which ("OZANA-1") used for joining or welding parts, made of A0-A3 grade alloys, and the other ("OZANA-2") — for working with AL4 stamps, AL9, AL11 and others. Distinctive characteristics of such electrodes are not only their ability to ensure arc stability and high quality of the formed seam, as well as that, that with their help you can cook as horizontal, and vertical seams.

OZA brand electrodes, which are made of aluminum welding wire: SvA1, SvA3, SVA5, SvA10

Parts made of pure aluminum are welded with such electrodes, as well as products from an alloy based on aluminum with silicon.

Electrodes brand "UANA"

These electrodes are used to connect parts made of aluminum alloys, belonging to the foundry and deformable group.

Electrodes, made of tungsten, with which devices for welding in the environment of protective gases are equipped.

Despite all its advantages, such electrodes have one significant drawback — it is rather difficult to ignite an arc with them.

Elitech WP tungsten electrodes

Electrodes for aluminum welding are produced by modern industry in a wide range and in sufficient quantity, but their cost is at a high level. However, you can seriously save on their purchase, if you make such electrodes with your own hands. It is quite easy to do, if you follow the following algorithm of actions:

- aluminum wire in diameter 3-4 mm and cut into pieces lengthwise 250-350 mm;

- prepare a smear for electrodes, which will include heavily crushed chalk, mixed with silicate glue;

- the mixture brought to a paste-like state is followed by an even layer (1-2 mm) apply to the prepared wire and dry the prepared electrodes until their coating is completely hardened.

With the help of electrodes, it is easy to weld aluminum parts. Making electrodes with your own hands will allow you to significantly save on this technological process.