Terminals for connecting wires: see, advantages and features of competent cable connection

Without wires you can not imagine the transmission of electricity. But it is necessary to do so, that these wires properly connect consumers to sources. Wire clamps must be performed correctly. How can this be done?

Improperly twisted wires can result in electric shock or power failure.. It is in incorrectly connected wires that short circuits most often occur. It is necessary to do so, so that the wires fit snugly together. Terminals help to make the right connection. What are the types and what are their differences? Let's talk about this later.

Requirements for twisting wires

There are only three requirements, namely:

- Length. Twisting should be long, since at a shorter length the collision area is smaller, so, heating is faster.

- To increase the reliability of the twist should be performed as tight and dense as possible. Pliers will help, they make reliable contact of wires.

- Soldering. It is necessary to solder the wires together to ensure the same reliability.

When twisting, you can use the usual insulation tape. But at the moment there are special caps. They are also called connecting insulating clamps. They are convenient and safe to use. The cap is like a glass, which has a spring to ensure the reliability of the connection. When choosing caps you need to consider, that there are caps on multi-core and single-core, calculate the total diameter (it should be less, than the diameter of the cap), learn, whether there is a special paste to prevent oxidation. It is inadmissible to twist wires of different materials.

see terminal

terminal blocks

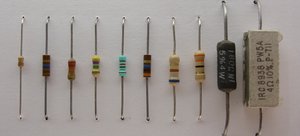

Nowadays, instead of twisting, special terminal blocks are more often used to connect wires. You can find many different options for terminal blocks for the price, quality, implementation. But all of them are made the same: there are cells in the case, where brass tubes with threaded holes on both sides are placed. Depending on the cross section of the wire, tubes of appropriate diameter are made.

The advantages of such terminals are, that you can combine different materials. Example, terminal connection of aluminum and copper or large cross-section and small. It is very convenient, because the connected aluminum and copper wires are oxidized, which causes inconvenience during further operation. Connecting terminals do not allow direct contact of wires with each other. You need to know the current when choosing, which will flow through the wires, it must be less than the rated current of the terminal block. Reliability, Of course, Less, than when soldering, but it is very convenient, and reduces installation time.

There are the following types of wiring with a terminal block:

- screws;

- spring not;

- knives.

screw terminal blocks

Installation of a terminal block does not cause trouble even to people, which are far from electricity. The wires are very easy to connect: you need to select the pad with the desired cell size, insert the wires inside and clamp them with screws. It is necessary to tighten with strong enough effort. You need to feel the moment, when the screw is tightened, so as not to damage the vein. You need to check the connection in about a year, if necessary tighten the screw. This refers to the shortcomings. It is also not possible to connect three wires.

You can also use a rivet instead of a screw. But then you need a special tool, and must be taken into account, that the design is then difficult to disassemble. Aluminum wire must be placed on the rivet, then a spring washer, copper wire and flat washer. This structure is compressed with a special tool. If the same materials are used, then the washer should not be placed between them. But the last puck must be the same.

spring terminals

There is an even more convenient option for electricians - it's spring terminals. They are used not only in everyday life, but also in large industry. An increased guarantee of a secure connection is guaranteed. For installation it is necessary to strip only isolation and to insert a core in the terminal block. The lever will tighten the wire and will not release it for anything. To pull the vein, just pull the lever back. In the people such terminal blocks are called "nuts" or clamping terminals.

The disadvantages include the fact, that you have to constantly select the terminal block by the number of connections. That is, if you need to connect three wires, then you need a terminal block, which provides for the connection of three wires. If there are more than six wires, then you have to combine the terminals with each other. Electricians recommend the use of spring terminals to separate the phase and neutral. It is also important to remember, that if you disconnect the lever once, then the reliability of the connection deteriorates further when re-clamped.

knife terminals

Knife terminals are also easy to use. No need to pre-clean the contacts when connecting. But force must be used, after all it is necessary to fix carefully a vein in a special knife. Such terminals are often called capped and used in cars, example, when connected to the headlight lamp.

Terminals for junction boxes

Terminal blocks are also used in distribution cabinets. They are presented in the form of a polycarbonate case with a copper platform, on which the holes for connection are located. They also have steel springs for fixing wires. It is very convenient to use terminal blocks, when it is necessary to connect carrying out grounding in one general. This type of terminal is suitable for connecting different types of wires. For convenience of installation on the case the data with value of rated current are put, diameter of wires, maximum allowable loads. There is also a paste to prevent overheating.

Terminals with fuse

Manufacturers have also provided additional protection for wiring and equip the terminals with a fuse. This type of connection has a holder, where the standard fuse is placed. Very convenient when operating electrical appliances without a built-in fuse.

Terminal blocks for lighting

Terminals for lighting can significantly simplify and reduce installation when laying electrical equipment for lighting. The case allows to maintain temperature close 105 degrees, copper contacts make it possible to improve conductivity, springs securely fix the cores. Such terminal blocks are sometimes made with a special paste, which protects the connection from oxidation and prevents conductors from overheating.

Terminals for lamps

When installing chandeliers, floor lamps or fans together with the chandelier can be used terminal block for lamps. It is very convenient to connect up to five wires at the same time. Equipped with self-clamping contacts, which facilitates installation and assembly, this also reduces the amount of consumables. All terminals are marked, there are convenient latches, which allow you to perform a quick installation.

Wires made of different materials

You simply cannot use a direct connection of conductors, made of different materials. Most often, these materials mean copper and aluminum, these are the most common types. At elevated temperatures, a gap may form between the conductors, which leads to a break in this circle. This gap is formed due to a number of factors:

- fever;

- connection resistance;

- the appearance of oxidation.

The result is a malfunction of the network or short circuit.

It is the screw or spring terminals that do not allow the connection of copper and aluminum with each other. No direct contact, veins separated by special dividing washers.