Capacitor for electric motor: how to choose and use, calculation of capacity for starting and working, connection and operation

Many owners often find themselves in a situation, when you need to connect such a device in the garage or cottage, as a three-phase asynchronous motor to various equipment, which can be an emery or drilling machine. This raises a problem, since the source is designed for single-phase voltage. What to do here? In fact, this problem is quite easy to solve by connecting the unit according to the schemes, used for capacitor. To implement this idea, requires a working and starting device, often referred to as phase shifters.

Capacity selection

To ensure the proper operation of the motor, you need to calculate certain parameters.

For working capacitor

To find the effective capacity of the device, it is necessary to perform calculations according to the formula:

- I1 - rated stator current, for measurement of which special pincers are used;

- Networks - mains voltage with one phase, (V).

After performing the calculations, the capacity of the working capacitor in the IFF will be obtained.

It may be difficult for someone to calculate this parameter according to the above formula. However, in this case, you can use another scheme to calculate the capacity, where you do not need to perform such complex operations. This method allows you to easily determine the required parameter based only on the power of the induction motor.

That's enough to keep in mind, what 100 The watt of power of the three-phase unit should correspond approximately 7 uF capacitance of the working capacitor.

The calculations need to monitor the flow, which is fed to the phase winding of the stator in the selected mode. It is considered inadmissible, if the current is more important, than the nominal figure.

For starting capacitor

There are situations, when the electric motor has to be included in the conditions of big loading on a shaft. Then one working capacitor will not be enough, so you have to add a starting capacitor to it. The peculiarity of his work is that, that it will work only during the start-up of the device no more 3 seconds, what the SA key is used for. When the rotor reaches the level of rated speed, the appliance switches off.

If due to negligence the owner left the starters on, this will lead to the formation of a significant skew in the currents in the phases. In such situations, there is a high probability of engine overheating. When determining the capacity should be based on that, that the value of this parameter should be in 2,5-3 times the capacity of the working capacitor. Acting in a similar way, you can achieve that, that the starting torque of the engine reaches the nominal value, as a result, there are no complications during its launch.

To create the required capacity, capacitors can be connected in parallel and in series. It should be borne in mind the operation of three-phase units with a capacity of not more than 1 kW is allowed in that case, if they are connected to a single-phase network in the presence of a working device. And here you can do without a starting capacitor.

A type

After calculations it is necessary to define, what type of capacitor can be used for the selected circuit

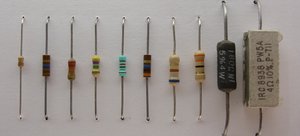

The best option, when a similar type is used for both capacitors. Usually the operation of a three-phase motor is provided by paper starting capacitors, dressed in an airtight steel case type MPGO, MBGP, KBP or MBGO.

Most of these devices are made in the form of a rectangle. If you look at the case, then there are their characteristics:

- Capacity (uF);

- Operating voltage (V).

Application of electrolytic devices

Using paper starting capacitors, you need to keep in mind the following negative point: they are quite large, while providing a small capacity. For this reason, for the efficient operation of a three-phase low-power motor has to use a large number of capacitors. If desired, paper can be replaced by electrolytic. In this case, they need to be connected in a slightly different way, where additional elements must be present, represented by diodes and resistors.

However, experts do not recommend the use of electrolytic starting capacitors. This is due to their serious shortcomings, which is manifested in the following: if the diode does not cope with its task, the device will start selling AC power, and this already threatens its heating and subsequent explosion.

Another reason is, that today on the market you can find improved with metallized coating polypropylene starting models of alternating current type SVV.

Most often, they are designed to work with voltage 400-450 St.. they should be preferred, considering, that they have repeatedly shown themselves on the good side.

High-voltage

Considering different types of starter rectifiers for three-phase motor, connected to a single-phase network, this parameter should also be taken into account, as operating voltage.

It will be a mistake to use a rectifier, the voltage of which exceeds the required order. In addition to the high cost of its acquisition will have to allocate more space for it due to its large size.

At the same time, models should not be considered, in which the voltage has a lower value, than mains voltage. Devices with such characteristics will not be able to perform their functions effectively and will fail soon enough.

To reduce the error when choosing the operating voltage , the following calculation scheme should be followed: the final parameter must correspond to the product of the actual mains voltage and the coefficient 1,15, the estimated value must be at least 300 St..

In that case, if paper rectifiers are selected for AC mains operation, then their operating voltage must be divided by 1,5-2. Therefore, the operating voltage for the paper capacitor, for which the manufacturer specified the voltage 180 V, in the conditions of work in an alternating current network will make 90-120 St..

To understand, how the idea of connecting a three-phase electric motor to a single-phase network is implemented in practice, perform an experiment using the AOL unit 22-4 power 400 (W) . The main task, which must be solved - starting the motor from a single-phase mains voltage 220 V.

The electric motor used has the following characteristics:

power indicator yesterday - 400 kw;

- mains voltage 220V AC;

- Current, all the characteristics of which were determined using electric measuring tongs in three-phase mode - 1,9 A;

- Star winding connection diagram.

With that in mind, the electric motor used has low power, when connecting it to a single-phase network, only a working capacitor can be purchased.

Calculation of the capacity of the working rectifier:

Using the following formulas, take the average value of the capacity of the working rectifier indicator 25 uF. A slightly larger capacity was chosen here, equal 10 uF. So we will try to find out, how this change affects the start-up of the device.

Now we need to buy rectifiers, as the latter will be used capacitors such as MBGO. Then on the basis of the prepared rectifiers assembly of necessary capacity is carried out.

Keep in mind as you work, that each such rectifier has a capacity 10 uF.

If you take two capacitors and connect them to each other in parallel, then the final capacity will be 20 uF. The operating voltage will be equal to 160V. To achieve the required level in 320 you need to take these two rectifiers and connect them to the same pair, capacitors, connected in parallel, but already applying a sequential scheme. As a result, the total capacity will be 10 uF. When the battery of working capacitors is ready, connect it to the engine. Then all you have to do is run it in a single-phase network.

In the process of conducting an experiment with the connection of the motor to a single-phase network, the work requires less time and effort. Using a similar unit with the selected battery of rectifiers, should be taken into account, that its useful power will be at the level of 70-80 % from rated power, the rotor speed will correspond to the nominal value.

Importantly: if a mains-operated motor is used 380/220 V, then when connecting to the network you should use the scheme "triangle".

Pay attention to the content of the tag: it happens so, that there is an image of a star with voltage 380 V. In this case, the correct operation of the engine in the network can be ensured, fulfilling the following conditions. First you have to "gut" the overall star, then connect to the terminal block 6 ends. Look for a common point in the front of the engine.