Shell and tube heat exchanger: classification and features of the device

Shell and tube heat exchanger is a type of heat engineering devices and performs the function of heat transfer from the coolant to the heated substance. Depending on the specific case, steam or liquid can act as a heat carrier. To date, the shell-and-tube model of the heater has become the most widespread.

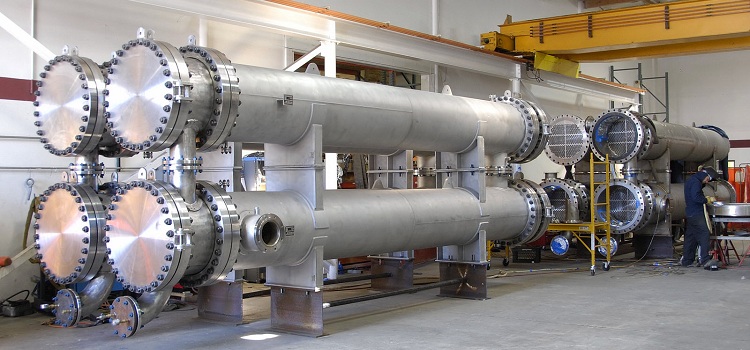

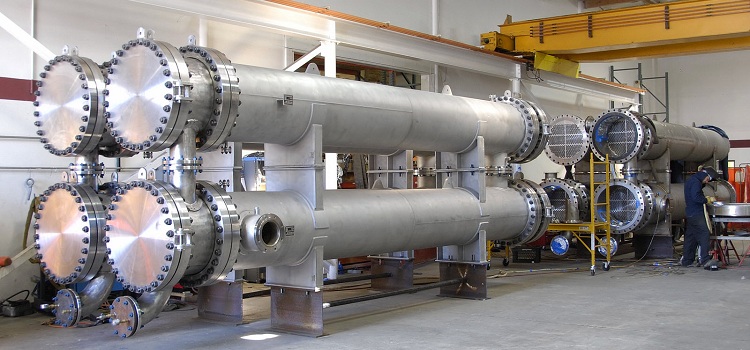

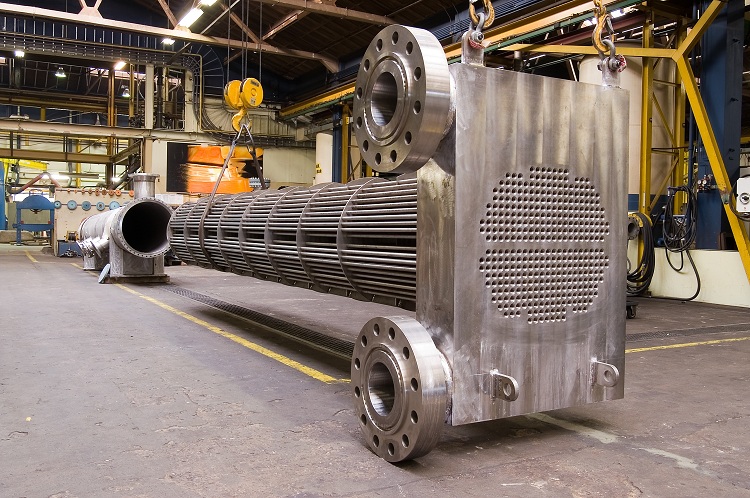

The heat exchanger is a rather complex device, used as a capacitor, heater or evaporator

Areas of use

Production of these devices began in the early twentieth century. It had to do with that, that thermal power plants needed heaters with a large surface area, operating at high pressure.

Shell and tube heaters are used in many industries, including:

- oil and gas industry;

- chemical production;

- food industry.

Virtually every production involves the release or absorption of heat, therefore, heat exchangers are in demand in various fields of human activity. The productivity of the equipment at the enterprises depends on their design and properties, as well as the operation of household air conditioners and heaters, cooling radiators in cars, etc.. d.

pay attention! Heaters of this type are most often used for cooling of working liquids and heating of the refrigerant for work of heat pumps..

Shell and tube heat exchangers are widely used as condensers, as well as evaporators. Today, thanks to the development of industrial technologies, the design of heat exchangers has become more advanced and continues to be modernized.

Advantages and disadvantages of shell and tube heat exchangers

From a constructive point of view, heat exchangers of this type are similar to the first models, which were produced in the early twentieth century. The modernization of these devices affected only some elements, however, the basis has remained unchanged. Modern materials, which are used for shell and tube heaters, allow to improve their operational properties.

Modern materials are used in the production of heat exchangers, significantly improve the quality of finished devices

Shell and tube heat exchangers have a number of positive qualities, which allows them to remain indispensable elements of various industries:

- resistance to water hammer in the system;

- ability to work with polluted environments;

- low heat transfer rates;

- good efficiency;

- durability;

- maintainability;

- resistance to high pressure;

- resistance to aggressive chemicals;

- operational safety;

- reliability and durability.

Heaters of this type have their drawbacks, including:

- rather large dimensions;

- high cost.

Device and principle of operation

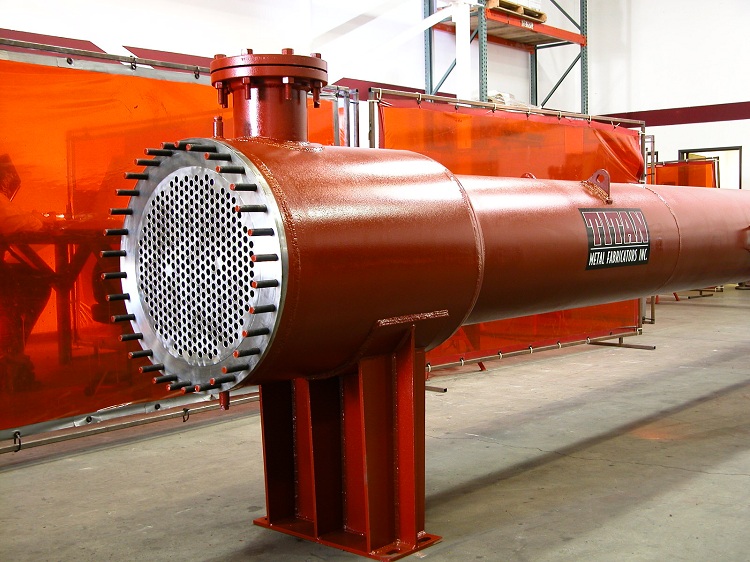

Shell and tube heat exchanger includes several structural elements. Consider the main ones:

- shroud (frame);

- distribution and directing chamber;

- internal system of tubes;

- pipe gratings;

- partitions and seals.

This model of device differs in the presence of a casing, which hides the inner tubes, hence the name - "shell-and-tube"

Two branch pipes are welded to the case. One of them is responsible for bringing the working environment, and the other - for the conclusion. Special flanges are welded at the end of the casing.

exept this, the composition of such a heater includes pipe gratings, between which the pipes are welded, equipped with remote grilles. This design forms the tubular system of the recuperator and allows the heater to be multi-pass.

Two pipes are inserted into the bottom of the recuperator, which are the same, as well as branch pipes of the case carry out bringing and deducing function. The bottom of the recuperator is equipped with flanges. The recuperator flanges are the corresponding housing flanges. The piping system of such a device is inserted into the housing. Lattices are fixed by means of special sealing elements and bolts between flanges of a recuperator and the case. It allows, if necessary, unimpeded repair of any element of the casing device.

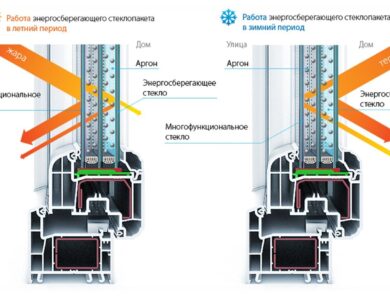

The principle of operation of this type of heater is as follows: hot and cold medium circulates through two different channels. The process of heat transfer is carried out between the walls of these channels.

Types of shell and tube heat exchangers

Shell and tube heater is quite complex, from a constructive point of view, device and has several varieties, which are worth paying attention to. Due to design features (the presence of the recuperator), shell-and-tube devices belong to the recuperative type.

Shell and tube heat exchangers belong to the recuperative type of such devices

exept this, depending on the direction of movement of working environments, shell and tube heaters are divided into the following types:

- direct current;

- crossover;

- countercurrent.

The shell-and-tube model received the name because of that, that pipe, on which the heat carrier circulates, placed inside the casing. There is a dependence of the speed of the working medium on the number of tubes, located in the casing. In turn, the higher the speed, the higher the heat transfer rate of the device.

Consider the main materials, from which such heaters are made:

- alloy steel;

- Stainless Steel;

- high-strength steel.

The tubes of such devices can be made of such materials:

- steel;

- copper;

- brass;

- titanium.

The use of such materials is related to this, that heat exchangers, usually, operated in harsh conditions and in contact with aggressive substances, which can cause corrosion.

Heat exchangers are made of materials, having high corrosion resistance, example, titanium or stainless steel

Importantly! Conventional steel is not suitable for shell and tube heat exchangers, because it has low resistance to corrosion.

Shell and tube models are also divided into types. Today it exists 4 types of these devices:

- heater, equipped with a temperature case compensator;

- heater with static (motionless) pipes;

- device with U-shaped and W-shaped tubes;

- floating head device.

Shell and tube heaters can be located in space horizontally, vertically or at a certain angle.

Increasing the heat transfer coefficient

The industry is not standing still - heat exchangers are constantly being upgraded. Improvement of technical characteristics is achieved through the use of the following methods:

- creating turbulent flows;

- execution of spiral inserts, due to which the longitudinal and transverse flow around the tubes is formed;

- production of profile and twisted pipes;

- use of mixtures, which include liquids and gases;

- creating vibration of surfaces, which are responsible for heat transfer;

- pulsating supply of the working medium.

The above methods can increase the heat transfer coefficient. It is also common to use several methods at the same time. This combination can significantly improve the performance of the shell and tube heater 2-3 times. It is also worth noting, that some methods not only increase heat transfer rates, but can also perform other useful functions. Example, turbulent flows prevent the formation of salt deposits on the inner walls of the pipes, which eliminates the narrowing of the lumen of the tubes.

Continuous improvement of the heat exchanger design allows to increase heat transfer and improve performance

Tips for choosing a heat exchanger

The program for calculating the shell-and-tube heater requires a clear formulation of the initial data. Good operation of the recuperative device requires a well-defined scheme. There are several provisions, which must be taken into account when choosing a shell-and-tube heat exchanger. These provisions are very important for calculations.

First of all, it is worth noting, that for liquid and gaseous heat carriers there is a speed of circulation on tubes. As mentioned above, the greater the speed, team, in accordance, better heat dissipation. For liquid media, the rate varies from 0,6 to 6 m / s. For gaseous media, the speed can be from 3 to 30 m / s. However, the amount of electricity consumed also depends on the speed, therefore in some cases the speed of the heat carrier is underestimated, to reduce electricity consumption.

When choosing tubes should pay attention to the material, of which they are made, as well as their diameter. The material of the tubes is selected depending on the working environment, which will circulate through them. It is important to remember that the more aggressive the environment, the more reliable the material of the tubes should be.

Importantly! If the cleaning of the system will be carried out using acid, then it is recommended to choose stainless steel tubes. Stainless steel has high anti-corrosion properties, has excellent resistance to aggressive reagents and, in addition, has a low coefficient of thermal conductivity.

Shell and tube heat exchangers are quite bulky devices, therefore, their size should be taken into account when choosing them, so that in the future there are no difficulties with their transportation and installation.

Large devices have a significant weight, which increases transportation costs

You also need to consider that, that after installation work in front of the recuperator there should be enough space, to carry out operative repair of the device if necessary. There should be so many places, so that the pipe system can be removed from the housing. The shell-and-tube heat exchanger must have a design, which takes into account free access not only to basic elements, but also to other spare parts. This is especially true of control devices.

Tips for operating a shell-and-tube heat exchanger

Heat exchangers of this type, however, are quite unpretentious devices, however, and they sooner or later need preventive cleaning or repair.

Repair of the heat exchanger entails some consequences - most often it is a reduction in heat transfer coefficient. The most vulnerable part of the shell-and-tube heater is the tube. Usually, they are the cause of failure. Knowing about this feature of heat exchangers, experts advise to buy them in stock. exept this, problems often arise, when adjusting these condensate devices. Any changes entail deviations in the area of heat transfer. Changes in the area of heat transfer, usually, are nonlinear.

It is quite difficult to make such a device with your own hands, and in some cases it is impossible. Shell and tube heat exchanger is a very complex equipment, for the production of which requires strict compliance with the technological process, which includes many stages.