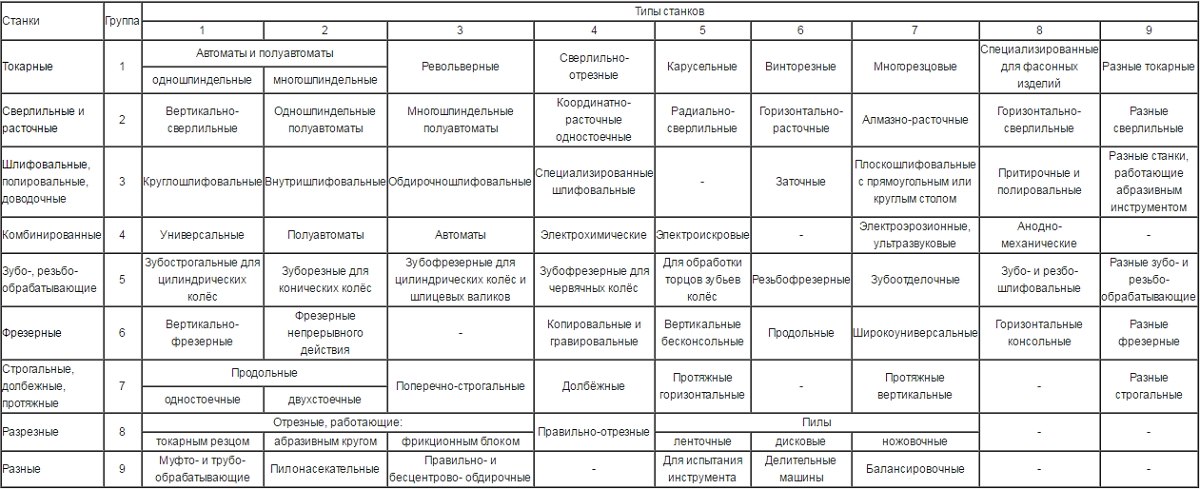

Metal-cutting machines - classification, marking, device

Metal-cutting machines, produced by domestic manufacturers, are divided into several categories, which characterize the corresponding classification. Identify, to which category this or that equipment belongs, it is possible on its marking, which says a lot about that, who understands it. However, no matter what category the metal-cutting device belonged to, the essence of processing on it comes down to that, that the cutting tool and the part make shaping movements, namely, they determine the configuration and size of the finished product.

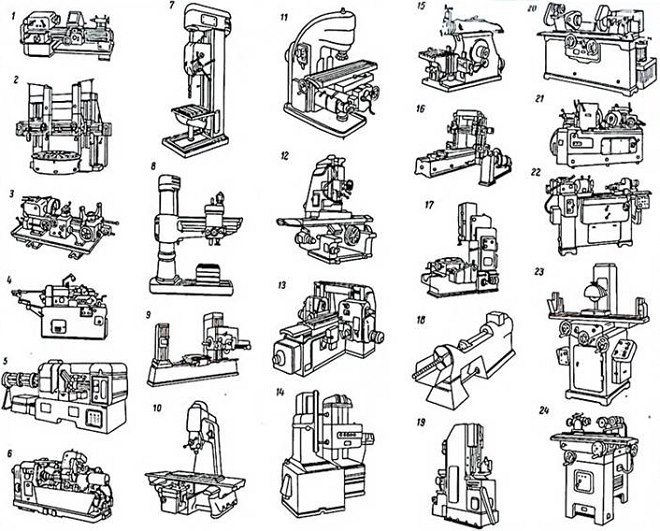

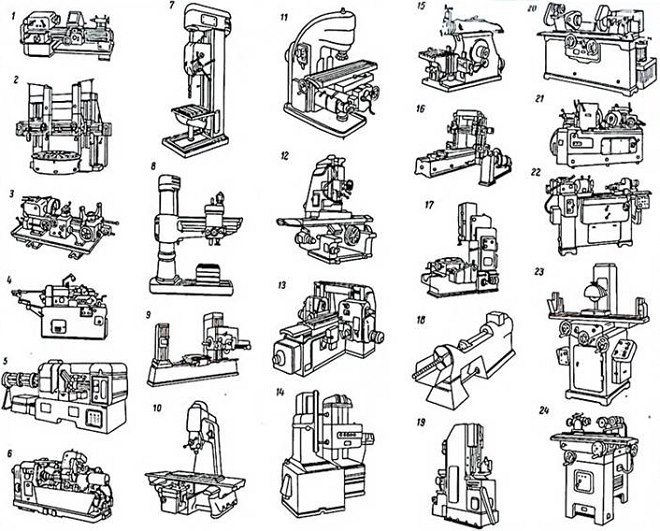

The most common types of metal cutting machines: 1-6 - lathes, 7-10 - drilling, 11-14 - milling, 15-17 - planers, 18-19 - long, 20-24 - grinding.

Types of metal-cutting equipment

Depending on the purpose, metal-cutting machines are divided into nine main groups. These include such devices:

- lathes - all types of lathes (in the label are denoted by the number "1");

- drilling and boring - machines for drilling and boring (group "2");

- grinding, polishing, finishing - metal-cutting machines for finishing, grinding, sharpening and polishing technological operations (group "3");

- combined - metal-cutting devices for special purposes (group "4");

- carving- and dental - machines for processing elements of threaded and toothed connections (group "5");

- milling - machines for milling works (group "6");

- grooving, planing and drawing - metal-cutting machines of various modifications, respectively, for planing, chiselling and stretching (group "7");

- different - equipment for cutting work, including drinking (group "8");

- different - examples of such metal-cutting units - without centers peeling, sawdust and others (group "9").

Groups and types of metal-cutting machines (press, to increase)

in addition, metal-cutting machines can belong to one of the following types:

- many- and single-spindle, specialized (semiautomatic and automatic), copying cutters, revolvers, drilling and cutting, carousel, front and special types of lathes;

- equipment for technological operations of boring and drilling: many- and single-spindle, semiautomatic devices, vertical drilling machines, horizontal and radial type, boring device coordinate, diamond and horizontal type, different drilling models;

- different types of grinding machines (flat, inside and round), peeling and polishing equipment, sharpening and specialized units;

- types of metalworking machines, designed for machining gear and threaded connections: gear cutters (including designed for processing conical wheels), gears - for cylindrical gears, gear milling, threaded, carving- and tooth grinders, dental, testing, thread-milling, devices for processing tooth ends and elements of worm pairs;

- metal-cutting machines, belonging to the milling group: console (vertical, horizontal and universal models) and consonantless (vertical devices, longitudinal, copying and engraving models);

- planing equipment and similar models: longitudinal machines, on which it is installed ??one or two racks; horizontal and vertical extension devices;

- cutting equipment: equipped with an abrasive wheel or a smooth metal disk, cutter or saws of various designs (tape, disk, hacksaws); correct-cutting types of metalworking machines;

- other types of machines for processing metal workpieces: dividing, used to control drills and grinding wheels, pollinating, balancing, right- and without centers peeled, sawtooth.

Vertical milling machine - one of the representatives of a large milling group

Classification of metal-cutting machines is also carried out according to the following parameters:

- by weight and overall dimensions of the equipment: large, heavy and unique;

- by level of specialization: machines, designed for processing workpieces of the same size - special; for details with different, but the same size - specialized; universal devices, on which it is possible to carry out processing of details of any sizes and forms;

- according to the degree of accuracy of processing: increased - P, normal - N, high - In, particularly high accuracy - A; also distinguish machines, on which it is possible to carry out especially exact processing - With, they are also called precision.

marking of machines

Equipment classification, intended for processing of preparations from metal, provides, what, seeing his markings, any expert will be able to tell at once, which metal-cutting machine is in front of him. This marking includes alphanumeric characters, which indicate the individual characteristics of the device.

The first digit is the group, to which the metal-cutting machine belongs, the second is a type of device, his type, third (and in some cases the fourth) - the basic standard size of the unit.

Deciphering the marking of metal-cutting machines

After the numbers, listed in the labeling of the model, there may be letters, by which it is determined, whether the model of the metal-cutting machine possesses special characteristics. Such characteristics of the device may include the level of its accuracy or indication ??for modification. Often in the designation of the machine the letter can be found after the first digit: this indicates, that in front of you is an upgraded model, in the typical design of which any changes were made.

As an example, it is possible to decipher marking of the 6M13P machine. The numbers in this notation indicate, that in front of us is a milling machine ( «6») the first type ( «1»), which belongs to the 3rd standard size ( «3») and allows to carry out processing with the increased accuracy (letter "P" ). The letter "M", which is present in the labeling of this device, indicates that, that it has undergone modernization.

levels of automation

Types of lathes, as well as devices for any other purpose, which are used in the conditions of mass and large-scale production, called aggregate. That's why they got this name, that they are completed with the same type of components (units): stanin, working heads, tables, spindle assemblies and other mechanisms. Quite different principles are used in the creation of machines, which are necessary for small-scale and single production. The design of such devices, characterized by high versatility, can be absolutely unique.

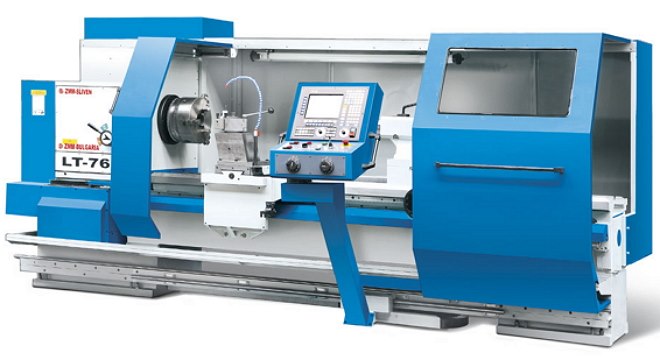

CNC lathe

Classification of lathes (as well as equipment of any other categories) the level of automation implies their division into such types:

- hand models, all operations on which are carried out manually;

- semi-automatic, in which part of the technological operations (workpiece installation, start the device, removal of the finished part) performed manually (all other operations, related to the auxiliary, are held automatically);

- automatic, for which it is only necessary to set processing parameters, all other operations they perform independently, according to the set program;

- CNC metal-cutting units (all processes on such machines are controlled by a special program, which contains a coded system of numerical values);

- metal-cutting equipment, belonging to the category of flexible automated modules.

The most striking representatives of metal-cutting machines are CNC devices, which are controlled by a special computer program. Such a program, which is entered into the memory of the machine by its operator, practically all parameters of operation of the unit are defined: spindle speed, processing speed, etc..

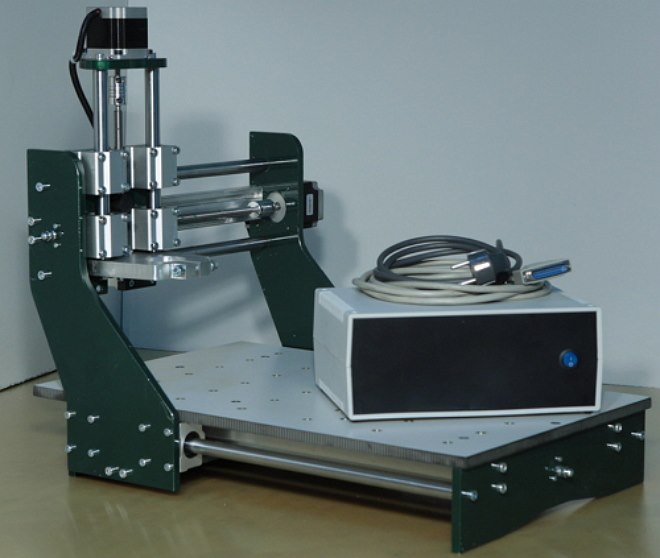

Even the most compact desktop machines can be equipped with the CNC system

All types of metalworking machines, equipped with CNC system, contain in their design the following typical elements.

- Remote controller (or console) operator, by means of which a computer program is stored in the machine's memory, that manages its work. in addition, by means of such panel it is possible to carry out also manual control of all parameters of work of the unit.

- The controller is an important element of the CNC system, by means of which not only control commands are formed, transmitted to the working elements of the equipment, and the correctness of their implementation is monitored, but also all the necessary calculations are performed. Depending on the degree of complexity of the unit model as a controller for its equipment can be used as a powerful compressor, and a conventional microprocessor.

- Screen or display, acting as a control and control panel for the operator. This element allows you to monitor the operation of the metal-cutting machine in real time, control the processing process, and if necessary, quickly change the parameters and settings.

The principle of operation of metalworking machines, equipped with a CNC system, incoherent. The program is written in advance, which takes into account all the requirements for the processing of a particular workpiece, then the operator enters it into the machine controller, using a special programmer. Teams, embedded in such a program, are fed to the working elements of the equipment, and after their execution the machine is automatically switched off.

Use of metal-cutting machines, equipped with numerical program control, allows to carry out processing with high accuracy and productivity, which is the reason for their active use to equip industrial enterprises, producing products in large series. Due to the high level of their automation, such units are perfectly integrated into large automated lines.

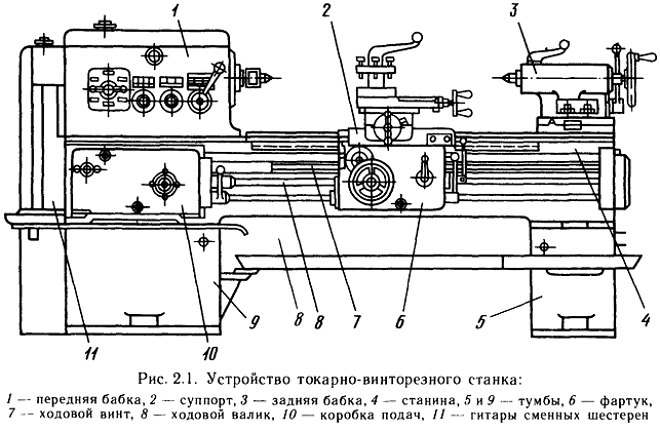

Device of a lathe

design of machines

All machines, which belong to the category of metalworking, have many common features in their design. Essentially, the device and technical characteristics of such units must ensure the correct execution of technological movements of two types:

- feed movement, which makes the cutting device or the workpiece itself;

- movement, by means of which cutting is carried out.

To perform these movements, as well as to ensure the stability of all other elements of equipment for metalworking, its design includes the following working bodies:

- management system, which is responsible for starting and stopping the machine, exercising control over all parameters of its work;

- node, by which the movement from the electric motor is converted and transmitted to the actuator;

- directly the drive itself, which can be electric, mechanical, pneumatic or hydraulic.

An important element of the design are also components of metal-cutting equipment, on which the cutting tool is installed and fixed. It is with the help of such nodes that the main function of the device is realized - machining of parts, made of metal.