Mini drilling machine with your own hands: circuit board machine

The PCB drilling machine belongs to the category of mini-equipment for special purposes. If desired, such a machine can be made with your own hands, using available components. Any specialist will confirm, that without the use of such a device is difficult to do in the manufacture of electrical products, circuit elements which are mounted on special printed circuit boards.

Simple mini machine for printed circuit boards

General information about drilling machines

Any drilling machine is required for this, to enable efficient and accurate machining of parts, made of different materials. There, where high precision machining is required (and this applies to the process of drilling holes), manual work must be excluded from the technological process as much as possible. Similar tasks are solved by any drilling machine, including homemade. It is almost impossible to do without machine tools when processing solid materials, for drilling holes in which the efforts of the operator may not be enough.

Design of a table drilling machine with a belt drive (click to enlarge)

Any drilling machine is a design, assembled from many components, which are securely and accurately fixed relative to each other on the load-bearing element. Some of these nodes are fixed to the load-bearing structure rigidly, and some can move and be fixed in one or more spatial positions.

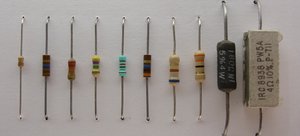

Example of engines, used in the manufacture of homemade drilling mini-machine

Basic functions of any drill, due to which the processing process is provided, there is rotation and movement in the vertical direction of the cutting tool - the drill. On many modern models of such machines the working head with the cutting tool can move and in the horizontal plane., which allows you to use this equipment to drill multiple holes without moving the part. in addition, automation systems are being actively implemented in modern drilling machines, which significantly increases their productivity and increases the accuracy of processing.

Below, for example, are several design options for homemade drilling machines for boards. Any of these schemes can serve as a model for your machine.

Features of equipment for drilling holes in printed circuit boards

PCB drilling machine is one of the types of drilling equipment, which, due to the very small size of the parts processed on it, belongs to the category of mini-devices.

Any radio amateur knows, that the printed circuit board is the basis, on which the components of the electronic or electrical circuit are mounted. Such boards are made of sheet dielectric materials, and their size directly depends on it, how many elements of the scheme must be placed on them. Any printed circuit board, regardless of its size, solves two tasks simultaneously: accurate and reliable positioning of circuit elements relative to each other and ensuring the passage between such elements of electrical signals.

Depending on the purpose and characteristics of the device, for which a printed circuit board is created, it can be placed as a small, and a huge number of circuit elements. To fix each of them in the board you need to drill holes. The accuracy of the location of such holes relative to each other is very high, because it depends on this factor, whether the elements of the scheme will be located correctly and whether it will be able to work at all after assembly.

Drilling holes in foil getinax on a homemade machine

The difficulty of processing printed circuit boards is also, that the bulk of modern electronic components are miniature in size, therefore, the holes for their placement should have a small diameter. A miniature tool is used to form such holes (in some cases even micro). Of course, what to do with such a tool, using an ordinary drill, is not possible.

All the above factors have led to the creation of special machines for forming holes in printed circuit boards. These devices have a simple design, but can significantly increase the productivity of such a process, as well as to achieve high precision machining. Using a mini drilling machine, which is easy to make with your own hands, you can quickly and accurately drill holes in printed circuit boards, intended for a complete set of various electronic and electrotechnical products.

Drilling machine from an old microscope

As a machine for drilling holes in printed circuit boards

From the classical drilling equipment the machine for formation of apertures in printed circuit boards differs in the miniature sizes and some features of the design.. Dimensions of such machines (including homemade, if the components are properly selected for their manufacture and their design is optimized) rarely exceed 30 cm. Naturally, and their weight is insignificant - to 5 kg.

Design of a self-made drill

If you are going to make a mini-drilling machine with your own hands, you need to pick up such components, as:

- bearing frame;

- stabilizing frame;

- plank, which will move the working head;

- shock absorber;

- handle for controlling the movement of the working head;

- device for mounting the motor;

- the electric motor itself;

- Power Supply;

- collet and adapters.

Drawings of machine parts (click to enlarge)

Drawing of the console of the machine

Let's understand that, what are all these units for and how to assemble a homemade mini-machine from them.

Structural elements of a mini-drilling machine

Mini drilling machines, collected with their own hands, can be seriously different from each other: it all depends, what components and materials were used to make them. However, as factory, and homemade models of such equipment work on the same principle and are designed to perform similar functions.

It will be easier to make a machine, if you take a sledge from a computer disk drive for the drilling head

The load-bearing element of the PCB drill design is the base frame, which also ensures the stability of the equipment during drilling. Based on the purpose of this structural element, to make a bed it is desirable from a metal frame, the weight of which must significantly exceed the total mass of all other components of the equipment. If you ignore this requirement, you will not be able to ensure the stability of your homemade machine, so, you will not achieve the required drilling accuracy.

The role of the element, on which the drilling head fastens, performs a transitional stabilizing frame. It is best made of metal rail or corners.

Carriage from the drive with the attached self-made corner under the engine

The bar and the damping device are designed to ensure the vertical movement of the drilling head and its springing. As such a bar (it is better to fix it with a shock-absorber) you can use any design (only important, that it performs the functions assigned to it). In this case, a powerful hydraulic shock absorber may come in handy. If you do not have such a shock absorber, the bar can be made with your own hands or use spring structures, removed from old office furniture.

Control of vertical movement of a drilling head is carried out by means of the special handle, one end of which is connected to the body of the drilling mini-machine, its shock absorber or stabilizing frame.

lever mounting

Engine mounts are mounted on a stabilizing frame. The design of such a device, which can be a wooden bar, collar, etc., Will depend on the configuration and design features of other components of the drill for printed circuit boards. The use of such fasteners is due not only to the need for its reliable fixation, but also that, that you must bring the motor shaft to the required distance from the movement bar.

Choosing an electric motor, which can be equipped with a mini-drilling machine, assembling with his own hands, should not cause any problems. Electric motors from a compact drill can be used as such a drive unit, cassette recorder, computer drive, printer and other devices, which you no longer use.

Engine from the hair dryer

Depending on that, what electric motor did you find, clamping mechanisms for fixing of drills are selected. The most convenient and versatile of these mechanisms are cartridges from a compact drill. If the appropriate cartridge could not be found, you can use a collet mechanism. Adjust the clamping device parameters as follows, so that very small drills can be fixed in it (or even "micro" size drills). Adapters must be used to connect the clamping device to the motor shaft, the dimensions and design of which will be determined by the type of motor selected.

Miniature collet chuck

Depending on that, which electric motor you have installed on your mini drilling machine, you need to choose a power supply. You should pay attention to this choice, that the characteristics of the power supply fully correspond to the parameters of voltage and current, for which the electric motor is designed.

Scheme of automatic speed control depending on the load for the engine on 12 V (click to enlarge)

The procedure for assembling a homemade device

As practice shows, to assemble a homemade machine for drilling holes in printed circuit boards is most convenient in a certain sequence. It is necessary to act in accordance with the following algorithm.

- Installation of a bed is carried out, and legs are attached to its lower side, if they are provided in the design.

- The moving bar and the frame of the holder are attached to the assembled frame, on which the drilling head will be mounted.

- The holder frame is connected to the shock absorber, also fixed on the frame of the equipment.

- The handle of management of movement of a drilling head is established, connected to the shock absorber or the frame of the holder.

- The electric motor is mounted, the position of which is carefully regulated.

- To the shaft of the drive motor by means of adapters the collet or the universal cartridge from a drill fastens.

- The power supply unit is being installed, which is connected to the electric motor by means of electric wires.

- A drill is installed in the chuck and securely fixed in it.

- The assembled homemade machine is tested, trying to drill a hole in the sheet dielectric.

In order for your homemade drilling mini-machine can always be disassembled and refined, it is best to use bolts and nuts to connect its components.

If you want to make your own mini-equipment for holes in printed circuit boards, you can always use the drawings and tips of those, who is already the owner of such a machine and is actively working on it in his home workshop.