Centrifugal water pump: principle of operation, see, rules of choice

Centrifugal water pumps are more popular than many pumping devices for this purpose, which is explained not only by their performance characteristics, but also versatility. The use of centrifugal water pumps allows to ensure the efficient operation of various systems, which include autonomous water supply systems, drainage, irrigation and firefighting, as well as drainage and sewerage systems.

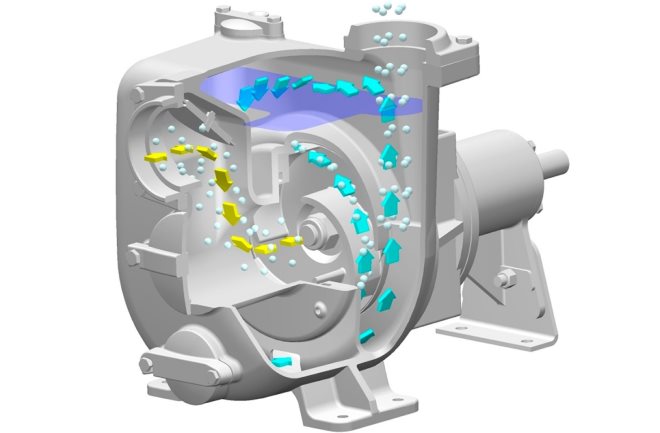

Centrifugal pump of a household class

Design and principle of operation

The main elements of the design of centrifugal pumps for water, which ensure the efficient operation of such devices, is:

- frame, which can be made of cast iron or steel alloy;

- drive electric motor;

- shaft;

- impeller with blades, which is fixed on the drive shaft;

- bearing assembly and sealing elements.

Schematic diagram of a centrifugal pump

The main working body of the centrifugal pump, which interacts with the pumped water, ensuring its movement, there are impellers. On the outer surface of the impeller is fixed at an angle to the blade, their curvature is directed to the side, opposite to the direction of rotation of this structural element, which provides greater efficiency of pumping equipment. Structurally, the impeller of a centrifugal pump can consist of one disk, on which the blades are fixed, or two disks, spaced a certain distance apart and connected by blades.

The considered pumps work at the expense of centrifugal force, affecting the pumped water when moving it inside the equipment together with the impeller blades.

The movement of water in a centrifugal pump

The principle of operation of centrifugal water pumps can be described in more detail as follows.

- Water, located in the inner working chamber, admires the blades of the rotating impeller and begins to move with them.

- When rotating, the centrifugal force throws water to the walls of the working chamber. So, excess water pressure is formed under the walls of the working chamber, which contributes to its ejection through the pressure pipe.

- Due to that, that under the walls of the working chamber of the pump is formed excess fluid pressure, in its central part a rarefaction of air is created. This leads to the suction of a new portion of the liquid medium through the inlet pipe.

So, acting on the above principle, centrifugal water pumps suck in and push out the liquid medium pumped by them in a continuous mode, which practically eliminates pressure pulsations in the serviced pipeline system.

The main varieties

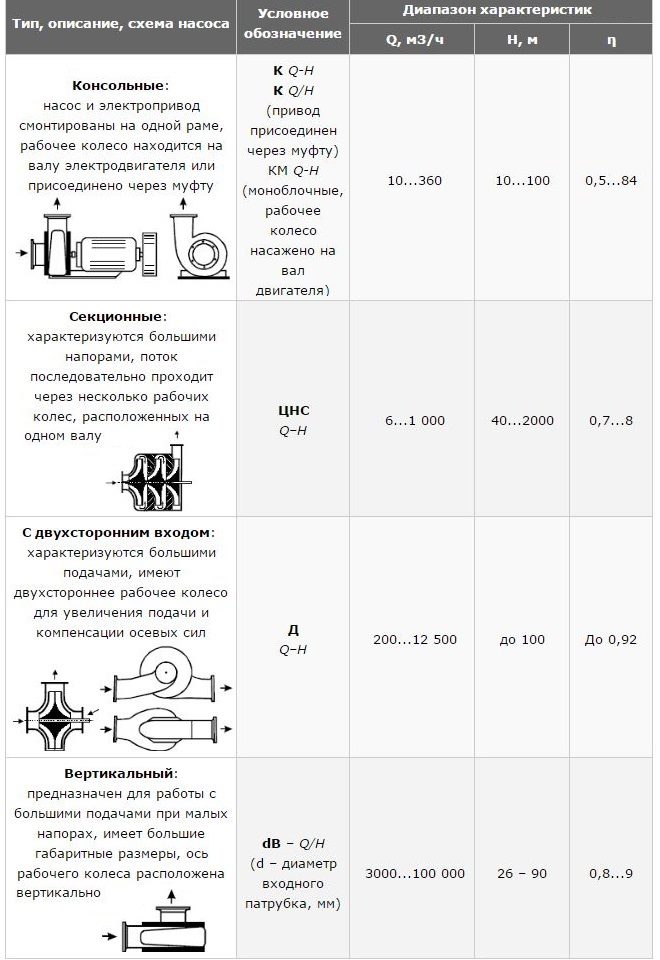

Modern manufacturers produce various types of centrifugal pumps for water, working, despite the different design, on the same principle. Centrifugal pumps can be divided into categories according to a number of parameters, what to consider, selecting such equipment to solve certain tasks.

Classification by design features

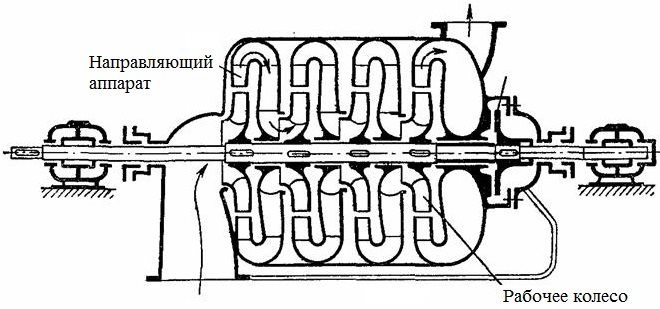

At household centrifugal pumps for water pumping (as in industrial) there may be different numbers of impellers. So, depending on this parameter are distinguished:

- centrifugal pumps of single-stage type, which are equipped with one impeller;

- multistage pumping devices, which can be equipped with two or more impellers, located in series on one drive shaft.

Scheme of a multistage sectional centrifugal pump

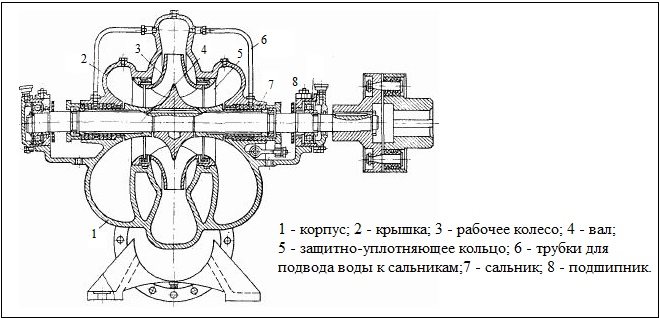

Centrifugal pumps can form a different number of streams of water pumped by them, depending on what they may be:

- single-threaded;

- two-threaded;

- multithreaded.

Centrifugal pump with two-way water supply to the impeller

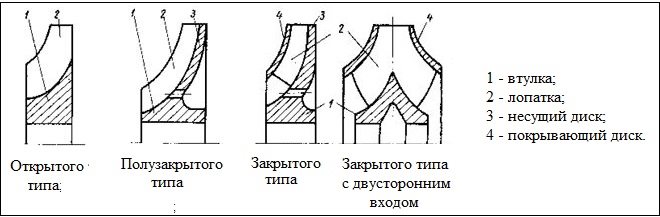

According to the design of the impeller, there are centrifugal pumps:

- with an impeller of the closed type, consisting of one disk, on the outer surface of which are fixed blades;

- with open impeller, which consists of two disks, spaced a certain distance apart and connected by blades.

Schemes of different impellers

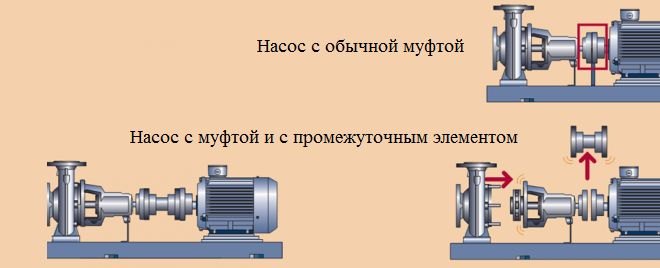

Depending on that, how the motor shaft connects to the drive shaft, pumping devices can be:

- direct drive;

- couplings;

- gear type.

Pumps with coupling

According to the principle of water drainage, pumped allocate:

- hydraulic machines with spiral drainage of the medium;

- pumps with annular guide grooves.

According to the location of the axis of the drive shaft (and, in accordance, the axis of rotation of the impeller) distinguish:

- device with a horizontal arrangement of the shaft axis;

- hydraulic machines of vertical type.

Classification by place of installation

Depending on that, how the centrifugal pump is positioned relative to the water it pumps, it may belong to one of the following species:

- submersible pump;

- surface centrifugal pump.

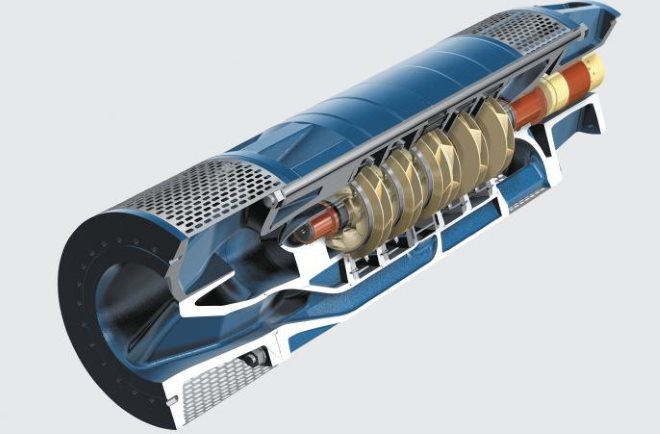

Immersion pumping devices in the process of their use are completely placed in the thickness of the water pumped by them. Housing of pumps of this type, which is made mainly of stainless steel, must be completely airtight, which is provided by use at its assembly of sealing elements. Depressurization of the housing of submersible centrifugal water pumps can lead to this, that their drive motor will simply fail.

Internal device of the centrifugal multistage pump of submersible type

Centrifugal pumps of surface type, as their name implies, are installed outside the source of water pumping, in the well pit, on a specially prepared site or in a separate room, if such equipment is planned to be used year-round. With the source, from which water is pumped out, such hydraulic machines are connected by a pipeline or a flexible hose.

Many modern models of centrifugal pumps (household and industrial) are equipped with float switches, allowing to automate work of pump installation. Surface pump, equipped with such a switch, itself shuts down at that moment, when the liquid level in the tank or well served by it decreases to a certain value, and turns on automatically, when this level rises.

Multistage surface-type self-priming centrifugal pump

Surface centrifugal pumps are used in those cases, when the depth of the well, from which you need to pump water, does not exceed ten meters. Submersible pumping equipment is used to service deeper wells, able to cope with such a task.

Scope

In addition to versatility, centrifugal pumping equipment has a number of other advantages, such as:

- absence of pulsations when water is supplied to the pipeline, which are characteristic, example, for piston pumping equipment;

- affordable price;

- high reliability;

- ease of use and maintenance, which can be done with your own hands, without the involvement of outside experts.

Відцентровий поверхневий насос в системі літнього поливу

If we talk about the use of water centrifugal pumps in the domestic sphere, then it is quite wide. Most often, household centrifugal pumps are used to solve the following problems.

- With the help of such hydraulic machines water is supplied to the autonomous water supply system of a private house or cottage from a well or well. Pumps, which are used for such purposes, can work with liquids, which contain a very small amount of insoluble solid inclusions.

- With the help of centrifugal pumps pump water from the well, wells, ground tank, natural or artificial reservoir and feed it under a certain pressure in the irrigation system of the homestead.

- Such equipment is also used to ensure constant circulation of the heat carrier in autonomous heating systems of country houses and dachas.. The use of special models of centrifugal pumps as an element of the heating system can significantly increase the efficiency of its work, and reduce energy costs (gas, electricity and fuel for the boiler). Household centrifugal pumps, used in heating systems, can be equipped with one or two rotors with special blades.

- For pumping water from basements and cellars, removal of accumulated fluid from the homestead, cleaning wells from silt deposits, special centrifugal pumps are also required for draining septic tanks and sewers. They belong to a certain type - drainage hydraulic machines. Centrifugal fecal pumps are used to equip sewer systems, where they are used to pump heavily contaminated liquids.

Submersible centrifugal pump in the water supply system from the well

The efficiency and convenience of using a centrifugal pump can be increased, if you equip it with additional technical devices, to which, in particular, include:

- coarse filters, that do not allow to get firm inclusions, contained in a liquid medium, into the inside of the device;

- check valve, which will not allow the fluid to go back to the source of pumping;

- float switch, with which the operation of the centrifugal pump can be switched to automatic mode;

- fluid level sensors;

- devices of the alarm system and protection of the driving electric motor against an overheat.

How to choose the right centrifugal pump

To you, how efficient the household centrifugal pump will be in operation, the correctness of his choice has a great influence. There are a number of factors to consider when buying.

- It is important to know the quality of the liquid medium, for pumping which it is planned to use a centrifugal pump. Evaluate in this case should be not only the number of insoluble inclusions in the pumped liquid medium, but also their particle size and type. If you ignore this requirement and choose a pump, which is not designed to work with a liquid medium with a certain degree of contamination, then you can not count on it, that the selected device will last a long time.

- Height or distance, to which it is necessary to transport the water pumped by the pump, is also important. Depending on this parameter, the centrifugal pump is selected according to the following characteristics, as pressure, which he is able to create.

- It is also necessary to determine the rate of water consumption, required for normal operation is served by the pump of the piping system. Focusing on this parameter, household or industrial centrifugal pump is selected according to the following characteristics, as productivity, which shows, how much fluid the pumping equipment is able to pump per unit time.

Choice of centrifugal pumps by design and characteristics

in addition, the choice of centrifugal pumping equipment is influenced by the following factors, as the depth of the well, well or tank, from which water will be pumped out, frequency of operation, as well as site characteristics, where it is planned to install a hydraulic machine.

When choosing a centrifugal pump should be guided not only by labeling, but also on special tables, by which you can pick up the device, optimally meets the requirements for it.

Preparation for work

Before starting the centrifugal pumping equipment, its inner working chamber should be filled with water. This is necessary for that, to avoid such a negative phenomenon, as idling.

Installing horizontal centrifugal pumps, remember, that the axis of rotation of their shaft and impeller should not be inclined. in addition, when installing centrifugal water pumps should be taken into account, that the flow rate of the fluid intake by such a device must be at least on 25% exceed the nominal value of the feed of the hydraulic machine. The pressure of the liquid, which is able to create a pump of a certain model, should on 5-6% exceed the distance from the dynamic level (the level of the liquid mirror in the water supply source) to the level, on which liquid, what is being pumped must be raised.

Centrifugal pump start diagram

Naturally, to be guided at installation of centrifugal pump hydraulic machines it is necessary on instructions of manufacturers or on the recommendation of consultants of trading companies, in which such equipment is purchased, and not on your intuition.

And finally a small video with recommendations on that, how to properly start the pump.