The main causes of matrix failures, inkjet and laser printers

Mainly, all printer malfunctions, regardless of its model and method of printing, occur due to improper operation or due to wear of the main modules of the device. From the whole mass of breakdowns, due to which office equipment stops working properly, you can select the most common, relating to different types of printers.

Dot matrix printer failures

Despite the abundance of inkjet and laser printing devices, dot matrix printers are still successfully used in offices and institutions, due to its reliability and low cost of consumables. But they are, as well as any office equipment, break for quite common reasons for this type of device.

The printer does not turn on

If the device refuses to turn on, the network indicator is off, and the print head is in place, that does not mean, the printer broke. Mainly, this problem may occur for the following reasons.

-

- There is no voltage in the socket. To check, connect any electrical appliance to it (iron, table lamp, etc.). If the devices do not turn on, so, or there is a fault in the socket, or there was a complete power outage in the building.

Check the voltage with other electrical appliances

Check the voltage with other electrical appliances - Defective electrical cable of the device. Perhaps, it is damaged or near the electric plug itself, or at the entrance to the device. You should also check the plug itself, if it is collapsible.

- The switch has failed. The mechanics of the switch itself may break, or unsoldered wires, connected to it.

- Fuse blown. Occurs either due to internal malfunctions of the device, or due to a surge in mains voltage.

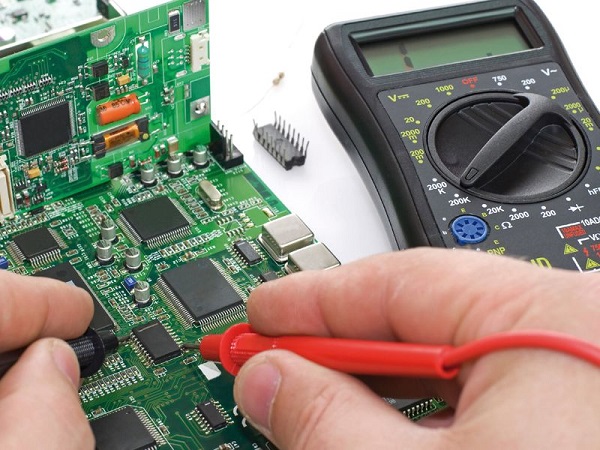

- No current is coming from the input circuits. Lack of voltage can cause breakdown of the transformer or stabilizer components. To accurately diagnose the cause requires "ringing" the input circuits with a multimeter and inspection of the electronic board.

- There is no voltage in the socket. To check, connect any electrical appliance to it (iron, table lamp, etc.). If the devices do not turn on, so, or there is a fault in the socket, or there was a complete power outage in the building.

The device turned on, but does not print

This situation can be caused by the following factors.

- Broken controller. Mainly, memory chips or signal processor burn out. Other components of the controller burn out less often.

- Data loop damage or broken contacts. Check the connection of the cable to the controller and the print head, as well as between separately located elements. It is impossible to exclude a fracture of a loop in any place.

- The electric motor has blown. To move the print head (PG) an electric motor is used, in the windings of which sometimes there is a short circuit. You will need to remove this part from the device and ring the windings for a short circuit.

- The GHG failed. The problem is solved only by replacing this part with a new one.