The piston pump is liquid: device and principle of operation

Liquid piston pump is one of the oldest devices, whose purpose is the pumping of liquid media. Piston pumps operate on the simple principle of displacing liquids, which is carried out mechanically. Compared with the first models of such devices, modern liquid piston-type pumps have a much more complex design, they are more reliable and efficient to use. So, piston pumps, produced by modern manufacturers, have not only an ergonomic and strong case, but also a developed element base, and also provide more opportunities for installation in pipeline systems. Due to this versatility, liquid piston pumps are actively used in pipeline systems as an industrial, and household purposes.

Piston pump for open hydraulic systems

Design features

The main element of the liquid piston pump is a hollow metal cylinder, in which all work processes take place, carried out with the pumped liquid. Physical impact on the fluid has a plunger piston. Due to this element, this liquid pump got its name.

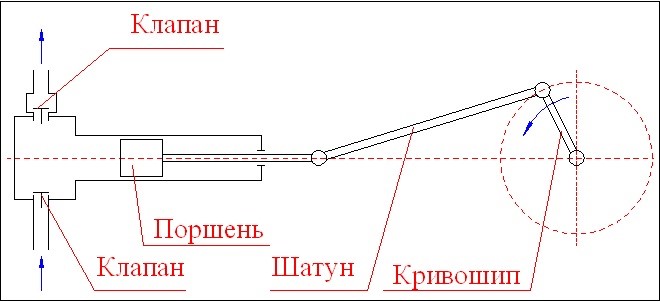

The principle of operation of the piston pump is based on the reciprocating motion of its working body, which acts as a hydraulic press. Thus in a design of such car, unlike classic hydraulic devices, there is a mechanism of valve distribution, as well as a number of additional structural elements (in particular, crank and connecting rod, forming the basis of the power part of the pump of the liquid piston type).

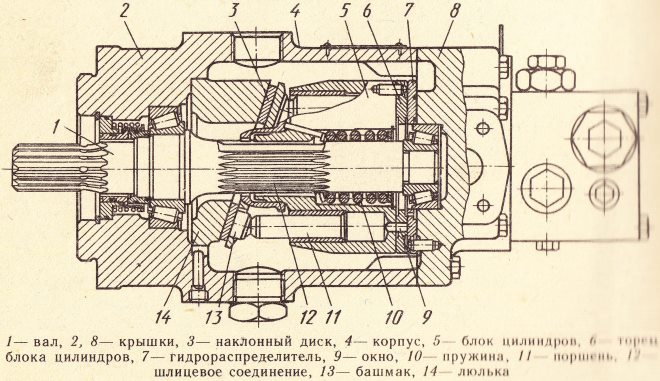

Axial-piston pump device

The principle of operation

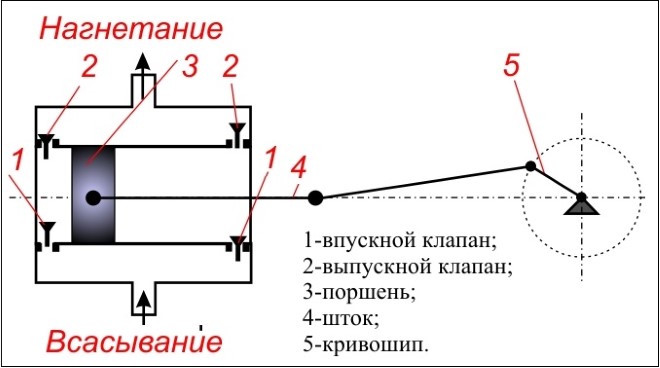

From most of those, who selects technical devices for equipping pipeline systems, experts hear: "Explain the operation of a piston pump with an air chamber". It is necessary to tell at once, that principle, which is operated by a liquid piston pump, invented several centuries ago, quite simple. It is as follows: carrying out translational movement, the piston creates a vacuum of air in the working chamber, due to which the liquid is sucked into the chamber from the supply pipe. At the return movement of the piston of such pump, which, according to some historical data, invented by an ancient Greek mechanic, fluid from the working chamber is pushed into the discharge line. Piston pumps, as mentioned above, are equipped with the valve mechanism, whose main task is, to prevent the liquid from getting back into the suction channel at that moment, when it is pushed into the discharge line.

The principle of operation of a one-way piston pump

In principle, on which piston pumps work, explains that fact, that flow, created by such devices, moves along the pipeline at different speeds, jumping. To avoid this negative phenomenon, use pumps, equipped with several pistons, which work in a certain sequence. Advantages, which are achieved when using liquid pumps with multiple pistons, is also that, that such devices are capable of pumping fluid even at that moment, when their working chamber is not filled with it. This is the quality of a multi-piston plunger pump, which is called "dry suction", relevant in many areas, where similar devices are used.

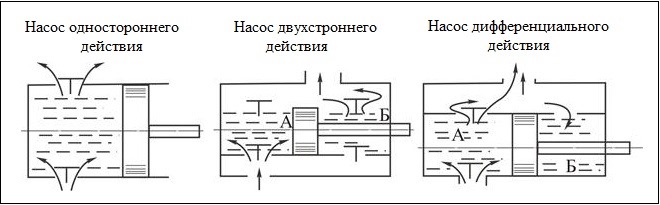

Piston pumps differ in the number of actions

Two-way pumps

Main reason, from which the double-acting piston pump was developed and began to be actively used, is the desire of manufacturers to reduce the level of pulsation of the fluid flow, injected into the pipeline system. To understand the benefits of using a double-acting pump device, enough to understand, how a reciprocating liquid pump of this type works.

The peculiarity of the device of the double-acting liquid piston pump is that, that the rod and piston cavities of this machine are equipped with individual valve systems. This is the design of a double-acting piston pump, the uniqueness of which can be seen even in the photo, allows not only to eliminate the ripple of the flow in the pipeline system, but also significantly increase the efficiency of the machine itself. Meanwhile, single-acting piston pumps, if you compare them with two-sided models, due to the simple design are more reliable and durable.

The principle of operation of a two-way piston pump

There is another constructive scheme of the piston pump, when using which it is possible to eliminate pulsating processes in pipeline systems. Pumping equipment, performed according to this scheme, which involves the use of a special accumulator. The main purpose of such accumulators, used to equip pumping stations, is, to store the energy of the fluid flow at the moments of peak pressure in the pipeline and give it away then, when such pressure is not enough for normal system operation.

However, whatever types of piston pumps are used and whatever additional technical devices are equipped with pumping stations, it is not always possible to eliminate pulsation processes in pipelines. In such situations, additional equipment is often used, which provides effective drainage of excess fluid outside the pumping station.

Areas of application

The scope of liquid piston piston pumps is quite wide, due to their high versatility. Meanwhile, the design of such machines does not allow them to be used in those cases, when it is necessary to pump large volumes of water or other liquid. One of the main advantages of these hydraulic machines is that, that their pistons, displacing the fluid through the discharge line, at the same time suck its new portion through the supply channel, which in the conditions of the dry cylinder is very important. This quality determines the purpose of reciprocating liquid pumps as the most efficient devices, used in the chemical industry.

Hydraulic piston pump for truck crane

Areas of application of liquid piston-type pumps are expanding due to the fact, that such equipment can be successfully used to work with chemically aggressive environments, certain fuels and explosive mixtures. Pumps of this type are also actively used for household purposes, with their help it is possible to create pipeline systems for autonomous water supply of private buildings and for irrigation. Meanwhile, deciding to use such a device, don't forget about it, that it is not intended for pumping large volumes of liquid.

Another area, in which liquid pistons of piston type are actively used, there is a food industry. This is due to the fact, that such devices have a very delicate attitude to the fluid pumped through them.

Advantages and disadvantages

If we talk about the benefits, which have piston-type pumps, employees for pumping liquid media, then one of the most significant can be attributed:

- simplicity of design, which is demonstrated even by pictures and schematic images of such devices;

- high reliability, which is determined not only by the use of high-strength materials for the production of such machines, but also the principle of operation of the piston pump;

- ability to work with media, which require special requirements for the starting conditions of pumping equipment.

The main disadvantage of this pumping equipment, mentioned above, is its low performance. Of course, you can expand the technical capabilities of such devices, but why do it, if this problem is solved with lower financial costs using pumping equipment of another type.

Choosing liquid piston type pumps, first decide, what such equipment will be used for. If you do not intend to pump too much fluid, then affordable and reliable piston-type liquid pumps are best suited for your goals.