Repair of bread machines with your own hands in case of various malfunctions

A malfunction in the home bakery can catch you by surprise. It is possible, Of course, take to the service center, but some malfunctions, that originated in your bread machine, can be eliminated independently.

Such breakages are most common in the rough:

- temperature sensor malfunction;

- Tena burnout;

- software failure in the control module;

- the electric motor has failed;

- the belt slipped;

- no power supply;

- faulty relay to reverse;

- breaking buckets for ingredients.

Other breakdowns are not excluded, inherent in other models and brands, because they may have differences in design features.

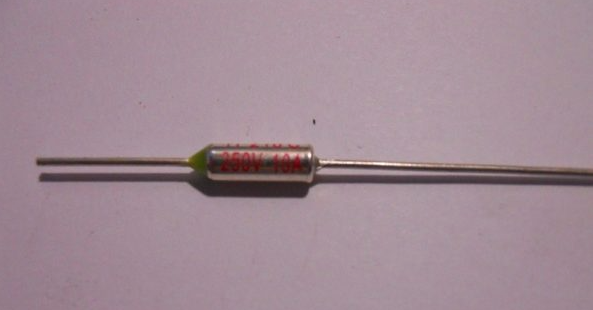

Temperature sensor malfunction

The quality of baked bread depends on the correct operation of the temperature sensor. If the thermal relay is faulty, then the bread will burn, or vice versa, will remain sluggish. It is this sensor that regulates the temperature in the oven during the baking program. The figure below shows, for example, what the temperature sensor of the Kenwood bread machine looks like.

Thermal fuses are often located near the thermistor. They do not allow to exceed the temperature above a certain, in case of failure of the thermal relay.

After disassembling the baking unit, it will not be difficult to find these details by external signs. They will also be easy to replace with new ones, pre-purchasing them online or at a service center.

Ten's burnout

Suspect that, that the heater does not work, very easy: bread just won't bake. To check it out, it is necessary to disassemble the device:

- unscrew the screws on the bottom of the oven and inside it, opening the lid;

- then carefully detach the bottom from the case, without breaking the wires;

- disconnect the wires from the terminal block;

- you will see a large metal tubular ring.

This is the heating element (tubular electric heater). In some bread machine models, it may be inside an iron bucket container. It can be checked by a tester for burnout. If the burnout is confirmed, it must be replaced with a new one.

Software failure in the control module

If your bread oven has started to behave strangely: some buttons have stopped turning on, the end of baking signal appears, when it first began, this may indicate a software module failure. Unfortunately, repair of bread machines with such breakage cannot be done independently. This should be done by qualified service center personnel. Otherwise, due to ignorance, you can aggravate the fault and repair the module will be more difficult and expensive.

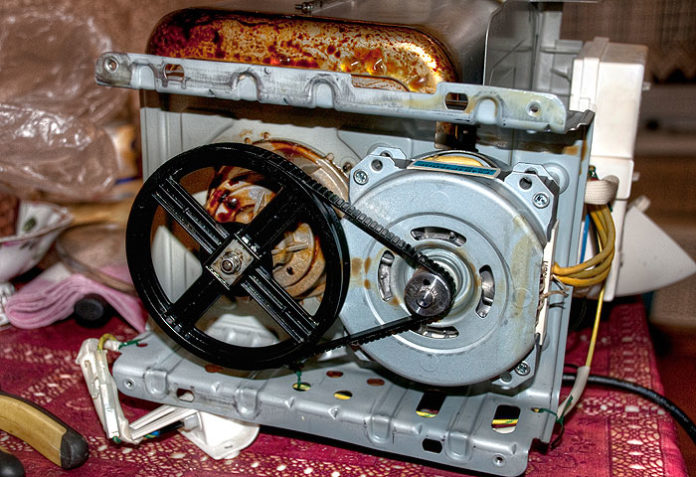

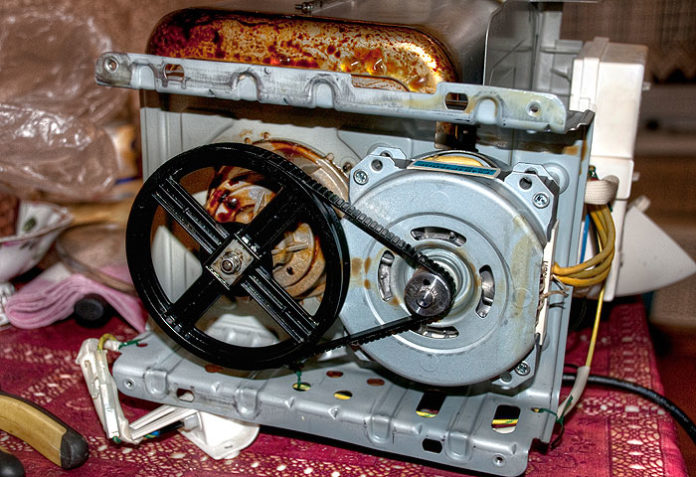

The electric motor has failed

This failure is easily determined. If you have switched on the unit, and the stirrer did not start to rotate and at the same time did not hear a sound of the working engine, this means, that the belt for the bread machine does not receive rotational movement from the pulley - faulty electric motor. Repair of this site, unit, as mentioned above, must be conducted by a master.

The belt slipped

If, when the noise of the running motor is heard after switching on the device, but the oar does not turn, or they do not mix well when the ingredients are backfilled, this may be due to wear or slippage of the timing belt from the pulley.

The bread machine belt can be detected, removing the bottom of the unit. As the bread machine drive belt wears, it is determined, whether it needs to be replaced with a new one.

No power supply

A common cause, when the bread machine simply does not turn on, there is a lack of power supply. First you need to check the electric plug and the cord itself. Next you need to check the power supply, usually, pulse. He has his fuse. But do not rush and change it. If after connecting to a light bulb circuit 100 W she lit up, then urgently turn off the power to further search for a short circuit. When the power supply is working, the light bulb should not glow, she can only blink. The power supply unit usually consists of a rectifier and a capacitor. This is where the fault lies.

Repair of the bread machine with your own hands in this case is possible, if you know a little bit about radio.

Wrong relay to reverse

In some inexpensive units, oar (mixer) removed from the shaft. To do this, complete with the device is a hook to remove it from the bread. But there are models, when the stirrer is folded. If after baking on the product you find the imprint of the oar, means, faulty reverse. Repairs to eliminate this problem of the bread machine should be carried out with the participation of a specialist.

Breaking buckets for ingredients

Repair of the bucket of the bread machine due to failure of the bearing and stuffing box can be carried out independently. Symptoms of that, that is the reason, the following:

- there was a small leak from the tank;

- wedging or complete jamming of the shaft.

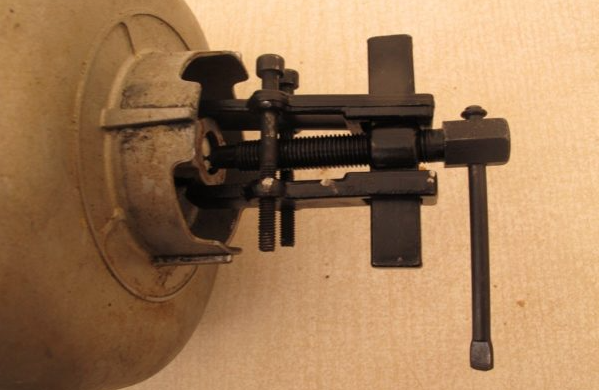

For a better understanding, below shows the repair of the bread machine LG with his own hands about replacing the bearing and seal (model of the LG HB-155CJ unit).

- You need to get a bucket and remove the ring, which is a stopper for holding on the shaft of a metal washer with plastic legs. At this stage, the ring, встановлене для фіксації підшипника можна не чіпати.

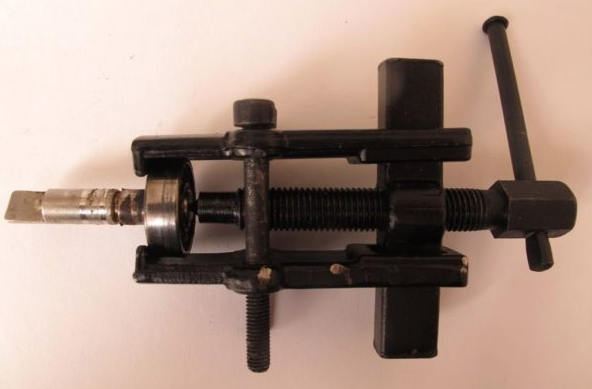

- The next step is to remove the bearing from its seat. You can't knock on a bucket, as it is fragile and can split. It will be correct to use a special two-dip camera. The puller is fixed in position, коли його зачепи добре закріплені в пазах на корпусі відра.

- A metal plate must be placed on the bearing shaft 1-2 mm thick.

- Then start screwing in the axis of the device until then, until the seal from the bearings falls out from the inside of the bucket. На наступному фото добре видно поганий стан деталей.

- Тепер можна зняти фіксацію з підшипника.

- Next, you need to remove the faulty part from the shaft with the same stripper and clean it from dirt using alcohol (solvents and gasoline must not be used to clean the shaft).

To continue, you need to buy the necessary spare parts: 608-and ball bearing (outer diameter - 22 mm, internal - 8 mm, height - 7 mm) and a special white oil seal.

Next in reverse order:

- Одягніть підшипник на вал і встановіть фіксатор.

- Gently press the bearing into your seat. It should be cooled before installation. You can still heat the bucket. Удари при запресовуванні не допускаються.

- Тепер можна зафіксувати вал спеціальної шайбою-стопором.

- Finally, you will need to install the seal. Repair of the bucket of the bread machine is finished!

Not all possible breakdowns of the bread baking unit were considered, as it is impossible to list them completely, and it depends on the characteristics of the models of different brands. Yet, troubleshoot, using this instruction, you can do it yourself.