Repair of centrifugal pumps and their maintenance

Though, that centrifugal pumps are reliable devices, used for pumping liquids, they may also need repair. Improper operation is not always the cause of centrifugal pump failures, this may be due to the quality being pumped, and with a number of other factors. If the centrifugal pump malfunctions, then you must first eliminate external causes and only then diagnose the equipment itself.

Disassembly of the centrifugal pump

Правильна експлуатація

To significantly extend the service life of the centrifugal pump and to face the repair of such equipment as rarely as possible, you must use this device properly. The operating instructions for the centrifugal pump require compliance with the following rules.

- Check before turning on the centrifugal pump, so that the working chamber is completely filled with liquid.

- A strainer must be installed in front of the suction pipe, which will protect the product from the inside from solid insoluble inclusions, contained in the pumped liquid medium.

- Protection of the drive motor against overloads is provided by a special latch, which is installed on the suction pipe, which restricts the flow of fluid entering the pump.

- When starting the pump, check it, so that the drive motor shaft and the impeller rotate clockwise.

- Tank depth, from which the liquid medium is pumped out, should not exceed the permissible level, specified in the technical passport.

- Pipe, on which the suction of the liquid medium from the tank, should have as few bends and joints as possible, and its inner diameter should be as large as possible.

- Pipe, through which the liquid medium from the pump is transported in a horizontal plane, it is desirable to place with a slope relative to the place of supply of liquid. If you meet this requirement is not possible, then the pump should be installed as high as possible above the ground.

During operation of this pump depressurization of input of a cable was allowed, as a result of which the motor winding burned out

The most common causes of breakdowns

First, what needs to be done, if malfunctions are noticed in the work of the pumping equipment, - stop its operation and start a thorough inspection of all components. Quite a common situation, in which pumping equipment requires maintenance or even repair, there is wear of seals. A number of reasons can contribute to a more active process of wear of glandular elements of pumping equipment:

- uneven rotation and beating of the drive motor shaft;

- tightening the bolts too much, which fastens the pump cover (seals best cope with the task of sealing in that case, if they are sufficiently moisturized);

- overheating of the drive motor;

- Improper maintenance or repair of the centrifugal pump (replacement of not all seals, etc.).

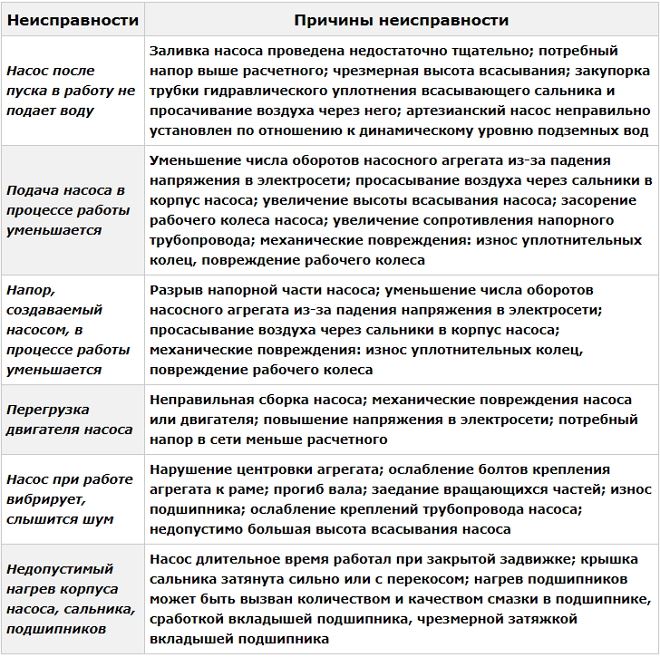

The main faults in the operation of centrifugal pumps

Another common cause of incorrect operation and even failure of pumping equipment is inaccurate centering of the drive motor shaft with the pump housing. The consequences in this case may be the destruction of glandular elements, and failure of bearing assemblies.

Centrifugal pump bearings are elements, requiring the most careful attention and regular care. To minimize the risk of failure of such components and provide them with the most optimal operating conditions, it is necessary to control the amount of oil.

Recommendations for repair of centrifugal pumps

Repair of centrifugal pumps, as well as any other technical devices, requires certain knowledge and skills. Meanwhile, if you follow the instructions for following this procedure and follow the recommendations below, then there should be no difficulties with its implementation.

Specialists, who have experience with pumping equipment, recommend to carry out its repair in the following sequence:

- Disassemble the device and carefully inspect the elements of the internal structure.

- Check the technical condition of the rotor, perform measurements of gaps in the landing elements of the sealing elements.

- Replace worn and failed bearings with new ones.

- Check the geometric parameters of the shaft necks and in case of defects to perform their grooving and grinding.

- After correcting all detected defects, assemble the pump, check the condition of its body and the correctness of the assembly.

Disassembling the pump, should be remembered (record or take photos) location of details

According to the above algorithm, scheduled repair of centrifugal pumps is performed, which, according to the recommendations of the manufacturers, should be carried out through each 4500 hours of its operation.

More technically complex repairs require pumping equipment after each 26000 hours of its operation. As part of such repairs with centrifugal pumps perform the following actions:

- replace the wheel and impeller;

- replace the sealing rings of the pump housing, spacer and clamping sleeves;

- in some cases, sectional pumps completely replace the sections;

- perform surfacing and boring of seats in the housing of the device;

- after assembly of the pump carry out its hydraulic tests.

If the seasonal operated pump will leave for the winter with moisture inside, then in the spring it can jam. The problem is solved by disassembly and cleaning

The greatest difficulty in the process of repairing a centrifugal pump according to the above scheme is the following procedures:

- disassembly of bearing assemblies;

- removal of inserts;

- removal of the half-coupling by means of the special stripper, complete with pumping equipment;

- dismantling of the unloading disk (heels);

- removal of a pressure flange.

When disassembling the centrifugal pump, the impellers must be removed very carefully from the shaft, it is important not to get them stuck. This procedure is performed in turn with each section. In that case, if the impeller is not removed or removed with difficulty, you can warm it up a bit.

You can heat the impeller with a portable gas burner

Assembling a centrifugal pump is a rather complicated procedure, in the process of which it is necessary to perform the following actions:

- check, how exactly the new details correspond to those, which have already been installed in the pump, as well as drawings of repaired pumping equipment;

- accurately adjust the new parts to the size of the seats, in which they will be installed;

- perform grinding and grinding of surfaces of details;

- tighten threaded fasteners evenly, using a torque wrench, allowing precise control of the force applied to such elements;

- when installing on the impeller shaft, check the accuracy of the formed axial clearance;

- control, that the error of perpendicularity of the face side of an unloading disk at its installation did not exceed 0,02 mm.

If you experience such a breakdown of the device during operation of the centrifugal pump, as the destruction of the impeller or housing, then you should not try to restore them, using for this, example, welding. Restored in this way, the wheel or body will not last long and can cause even more serious damage.

These are the details of the pump, damaged by "dry running", are not subject to repair and require replacement

The following procedures are performed during maintenance of centrifugal pumps at home, as:

- checking the technical condition of bearings and their replacement, if necessary;

- crankcase cleaning and flushing;

- oil change in bearing assemblies;

- check of a technical condition of stuffing elements;

- washing of oil-conducting channels;

- check the centering of the pump and, if necessary, adjust this parameter.

Faced with the failure of the centrifugal pump, you have to evaluate, how much can it cost to repair. In some cases, when the pump failure is too severe, its repair will cost much more, than buying new equipment. In any case, the decision on the feasibility and possibility of repairing the centrifugal pump should be made only after a complete diagnosis of the equipment and identify the causes of its failure..