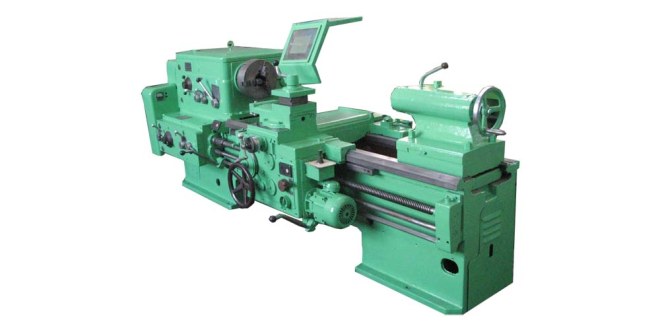

DIP lathe 300 - Specifications

DIP lathe 300 the same, as well as its newer modification 1M63, well known to specialists, whose activities are related to the need to perform metal-cutting operations. Machines of this model, differing in rather wide functionality, successfully used to perform various cutting operations as with black, and with non-ferrous metals.

DIP lathe 300

Basic data about DIP 300

Machine of turning and screw-cutting group DIP 300, as well as a similar DIP model 200, began to be produced by domestic industry in the 30s of last century and for several decades was successfully used by almost all machine-building plants. Such machines are most widespread at enterprises, producing metal products and single small series.

DIP machine 300, as well as its more advanced version 1M63, has a high reliability of the spindle and carriage, due to the peculiarities of its design. With this machine you can perform the following types of metalworking operations, as turning cones, boring, threading of various types (metric, inches, pitches, modular), drilling, turning of internal and external surfaces.

In the photo - spindle and gearbox DIP 300

To work at the DIP 300 use cutters made of high-speed steel, differ in the increased durability. Such cutters are optimally suitable for that, to process details by cutting as black, and non-ferrous metals. Depending on the characteristics of the material being processed, a cutter with soldered carbide inserts can be used as a tool..

An important feature of the machines of this series is that, that the upper sled of their caliper can be moved, this makes it possible to process long conical parts on such equipment. The caliper itself is driven by a separate electric motor, which makes it possible to move it in the longitudinal and transverse direction at high speed. It should be noted, that almost all equipment of this series has such a possibility (in particular, did not have its popular lathe DIP 200), which significantly increased the processing time of parts.

Of the main characteristics of this model of lathe should be noted the following:

- The diameter of the workpiece to be installed may vary depending on the selected machining scheme: when installing above the recess - 900 mm above the frame - 700 mm, when processing over the caliper - 350 mm.

- Height of centers - 315 mm

- Technical possibilities of this machine allow to process preparations on it, whose weight can be up to 3500 kg.

- Spindle characteristics: hole diameter - 105 mm; number of speeds - 22 direct and 11 reverse; speed - 10-1250 rpm (direct), 18-1800 rpm (the reverse); drive power to ensure the main movement - 13 kw.

- Limits / number of steps for different types of threads: metric - 1-224 mm, inches - 28-0,25 thread per inch, modular - 0.25-56 modules, pitches - 112-0,5 patch diametrical.

- The maximum value of movement of cutter slides - 220 mm.

- Maximum feed rate: longitudinal - 1260 mm, transverse - 400 mm.

- Technical characteristics of electric motors, which the machine is equipped with: to ensure the main movement - 14/1450 kW / rev / hv, for fast caliper movements - 1,1/1400 kW / rev / hv, for coolant supply - 0,12 kw.

- Caliper movement speed: longitudinal - 4,5 m / min, transverse - 1,6 m / min.

- The value of the maximum possible movement of the quill of the rear headstock - 240 mm.

- Model weight - 4,3 T.

As can be seen from the technical characteristics of this machine, it is far superior in its capabilities and technical equipment to many of its counterparts, in particular the equipment of the popular DIP model 200.

DIP lathe 200

Advantages of the model

High popularity of machines of this model, does not decrease for several decades, due to their advantages. These include the following features.

-

-

- Power gears are made of alloy steel, which is subjected to hardening.

- The machine has high temperature stability and resistance to vibration, which provides high accuracy of processing of details.

- You can achieve a high speed of rotation of the spindle in the opposite direction, which significantly reduces the time to perform threading.

- Operation of the machine differs in high safety due to special protections of the cartridge and cutting area, mechanical and electrical locking systems.

-

General view of the DIP lathe 300 1M63

- The bed has two-prism guides, which provides not only exceptional reliability and durability of the machine, but also high accuracy of processing of details, which is stored throughout the life of the equipment.

- Two electromagnetic couplings are installed in the gearbox of the machine, which allows to switch the direction of movement of the caliper almost without stopping work and as quickly as possible. The kinematic chain of the gearbox itself is characterized by high rigidity.

- Friction DIP 300 regulated quite simply. This characteristic is very relevant, as this equipment is used mainly by small businesses, which may not have highly qualified repairmen.

- The machine gives the chance to process long conical details due to simultaneous cross movement of the cutter and longitudinal - a support.

The machine has a two-axle gearbox with a closed structure, which is more reliable and convenient in operation in comparison with boxes, equipped with special guitars (such boxes, in particular, were installed on DIP models popular at the time 200).

Adjustment of parameters of a transmission is carried out by means of special handles and change of gear wheels. This makes it possible to use a machine for cutting threads of any type: metric, inch, modular and drinking. With the help of a machine you can also cut a special and particularly precise thread (if you do not use the gearbox, and connect the lead screw directly - through a system of special wheels).

It is necessary to dwell on the characteristics of the caliper of this machine, which has a lot of advantages over equipment, which was installed on earlier models, in particular on DIP machines 200. DIP support 300 has a cross design and has the following characteristics.

Support DIP lathe 300

-

-

- Can be installed in the head 4 cutter.

- The maximum distance between the axis of the centers and the edge of the tool holder - 320 mm.

- Longitudinal movement, carried out in one turn of the limbus, – 300 mm.

- The price of one limb division, corresponding to the transverse displacement by the value of the diameter, – 0,05 mm.

- Speed, which is achieved by the caliper with accelerated movement: in the longitudinal direction - 4,5 m / min, in cross - 1,6 m / min.

-

Longitudinal movement of the DIP machine caliper 300 carried out on the guides of the frame, and transverse - on the guides of the carriage. Which is convenient, such movements, if necessary, can be performed both by hand drive (slower), and with the help of a mechanical drive (in accelerated mode). The upper part of the caliper together with the cutter head placed on it can also be moved manually or by using a mechanical drive.

Features of the gearbox of the DIP machine 300

The gearbox of the machine of this model is attached to its main part - on the left side of the frame. All mechanisms of a box are driven by means of a shaft with a pulley, to which by means of a V-belt transmission and rotation from the electric motor is transferred. Step regulation of speeds in a box is carried out at the expense of use of gear wheels of various diameter, driven by a central shaft.

Gearbox 1M63.

Using such a box allows you to get 24 speed, which are switched by connecting the gears in series, having different characteristics. In those cases, when the spindle needs to provide high speed gears are not used, rotation from the motor is transmitted directly. In this mode, the DIP 300 works with the minimum noise and with the maximum efficiency.

The technical capabilities of the gearbox allow a wide range (in 4-16 times) increase the pitch of the cut thread, as well as promptly change the direction of movement of the caliper. Changing the spindle speed is due to that, gears with different characteristics are engaged (diameter, number of teeth). Change gears, engaging, is performed by a special handle. Roller and ball bearings are used to facilitate the rotation of the gears on the shafts.

Hollow spindle supports, made of stainless steel, serving reliable bearings. At the same time in a forward support the two-row radial bearing of needle type is used, and in the back - the bearing of radial and persistent type. These bearings ensure easy rotation of the spindle and take the load, to which he is exposed.

The rotation is transmitted to the spindle by means of a plate friction clutch, which is actuated by a special handle. in addition, due to the use of such a clutch changes the direction and stops the rotation of the machine spindle.