TV-6 lathe - technical characteristics, device

TV-6 lathe, the release of which was established in the 80s of the last century at the Rostov plant of training machine tools, was specially designed for that, to teach him the basics of the profession of turner. The device of this model was traditionally equipped with workshops of schools and special educational institutions.

Training lathe TV-6

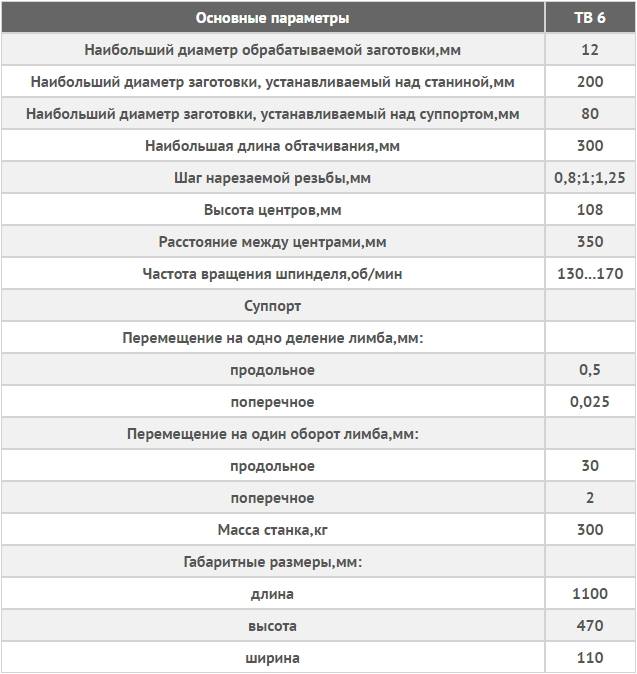

Technical characteristics of the TV-6 training lathe

Because the TV-6 lathe was created for that purpose, to train novice professionals, it has rather modest technical characteristics. The simplest turning operations can be performed on the equipment of this model:

- trimming the ends;

- drilling holes;

- boring and grooving of cylindrical and conical parts;

- metric thread cutting;

- segment of the workpiece.

TV-6 lathes may be used only for the manufacture of steel and non-ferrous metals, which are not emitted when processing volatile compounds and fine dust, which can have a detrimental effect on the student's body.

The main technical characteristics of the TV-6 machine

Weight (300 kg) and dimensions of the TV-6 lathe (div. Photo) impress with their minimalism: length - 1440 mm, width - 470 mm, height - 110 mm. Thanks to such parameters to install this unit will not be difficult even in a small workshop. Technical characteristics of the TV-6 machine allow to process details on it, the maximum diameter of which is:

- 20 cm - above the frame;

- 8 cm - above the caliper.

On the TV-6 machine it is possible to process preparations, the maximum length of which is equal to 35 cm, and the maximum length of the drilling site - 30 div. An important characteristic of any lathe is the height of its location of the centers above the support surface of the cutter, in this model of equipment it is 12 mm. You can use cutters on the machine, the height and width of the handle which does not exceed 12 on 12 mm.

The caliper with the following technical characteristics is installed on the TV-6 lathe.

- Valid value of transverse displacement - 100 mm. On one division of a scale on a limb such movement makes 0,025 mm

- Valid value of longitudinal movement - 300 mm. It is one division of the scale on the limbus 0,25 mm

- Cutter sledges are moved to the maximum size 85 mm. On one division of a scale of a limb such movement makes 0,025 mm

- Possibilities of a support allow to cut on the TV-6 machine a metric carving of three types.

- There are three stages of feed adjustment for longitudinal movement of the machine support.

- In the longitudinal direction, the caliper of the machine can feed at the limit values 0,12 rpm.

The cutting sledge of the unit together with the cutter holder can turn on 45 degrees.

The equipment of the TV-6 lathe includes a spindle, which has the following characteristics.

- Speed of rotation, performed in the forward and reverse directions, - to 700 rpm.

- In the through hole in the spindle you can insert a rod with a diameter up to 12 mm

- To adjust the direct rotation of the spindle is provided 6 degrees.

- Spindle taper Morse - No. 3.

The TV-6 lathe does not have a spindle braking system and locking the handles of its node.

Structural elements of equipment

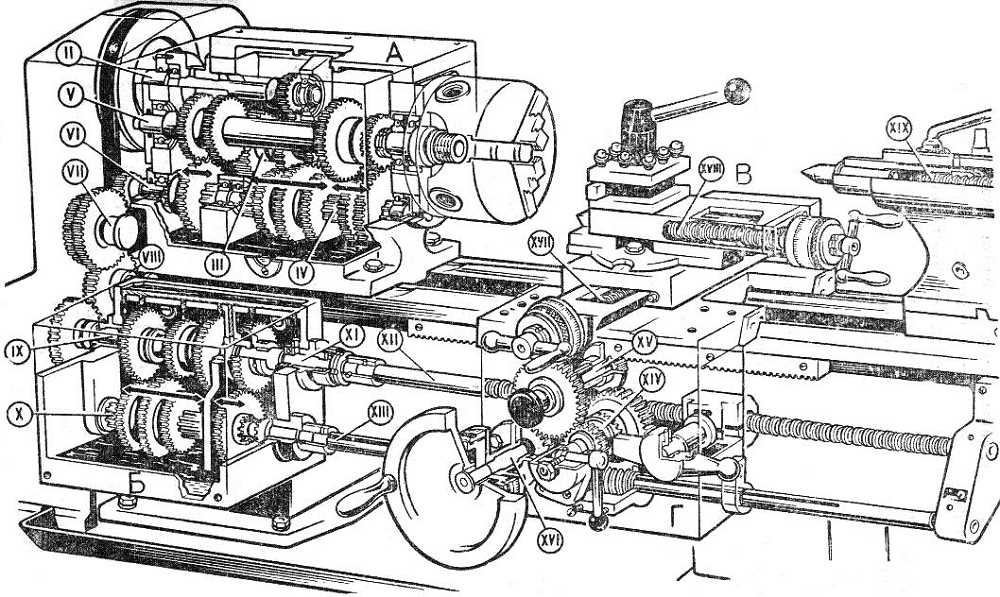

The TV-6 lathe consists of the following components, as:

- feed control box;

- front and rear cabinets;

- protective screen;

- oil supply pan;

- front grandmother;

- apron device;

- back grandmother;

- bearing frame;

- elements of the electrical system;

- guitar;

- protective cover.

The main components and controls of the TV-6 machine

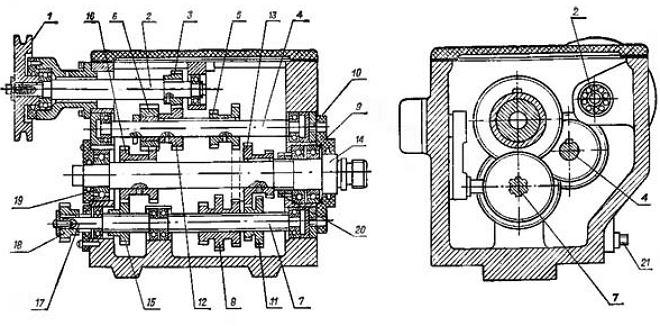

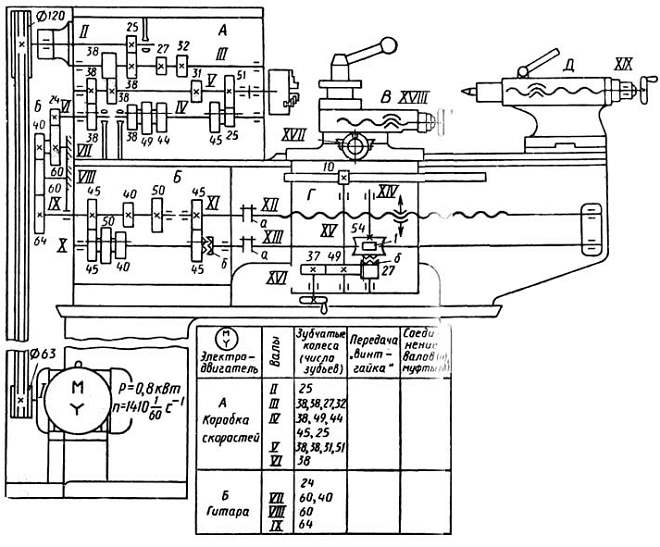

Feed box of the TV-6 lathe, which is actuated by a gearbox by means of gears of the transmission mechanism, consisting of:

- two shafts;

- five gears with different parameters;

- block gears;

- travel roller;

- couplings;

- round nut;

- switching handles;

- drain plug.

The handle on the front side of the gearbox allows you to determine the parameters of the cut on the workpiece thread.

Another handle, located on the gearbox panel, is responsible for the inclusion of the running roller of the machine. The device of this unit of the TV-6 machine makes it impossible to simultaneously turn on the lead screw and the running roller. Models of lathes are equipped with a similar safety system, belonging to the category of industrial equipment. Lubricate all gear units (gears and friction surfaces) provided by oil, which is fed from the trough with the help of special wicks.

Front headstock device

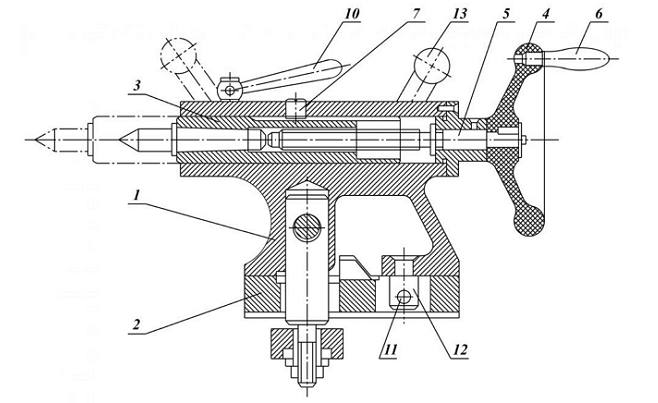

Rear headstock device

The front pedestal has a U-shaped configuration, and to increase its rigidity in the upper and lower parts there are special ribs. The drive motor of the unit is installed on its rear side, and on the front - a button, which controls its reversible inclusions. The rear curbstone of TV-6 has a similar design, a shield with electrical equipment is mounted on it.

Rear grandmother, in which there is a landing hole under the Morse taper №2, includes the following elements:

- basis;

- node housing;

- connecting screws;

- quill;

- screw key;

- flywheel to control the movement of the quill;

- handles for fixing the quill and the rear headstock.

The design of the rear headstock allows you to move the quill a distance to 65 mm.

The bed of the device, due to which all its structural units are connected and maintained in a given position, has a box structure with several windows. There are two prismatic guides on the frame, one of which (front) the carriage moves, and the second (posterior) - rear head unit. The load-bearing elements of the frame itself, in front of which the rail with the running screw fastens, there are two cabinets.

The most important mechanism of the TV-6 lathe is its apron, in which it is necessary to highlight the following elements:

- four gears (two worm and two rail);

- control handles;

- flywheel for manual feed control;

- uterine nut;

- running roller, which is responsible for the longitudinal feed of the caliper;

- shaft.

Carriage the machine

The support of the TV-6 lathe is composed of four carriages. This unit of equipment is responsible for fixing the cutting tool and its movement during metalworking. Tool holder, in which the working tool is fixed, is located on the carriage №4, it is able to move along the guides of the carriage №3 only in the longitudinal direction. The carriage №3 is rotary, which is attached to the second carriage. Carriage №2 is mounted on carriage №1, it is able to move in its direction in the transverse direction. The carriage №1 moves along the guides of the frame - the longitudinal direction.

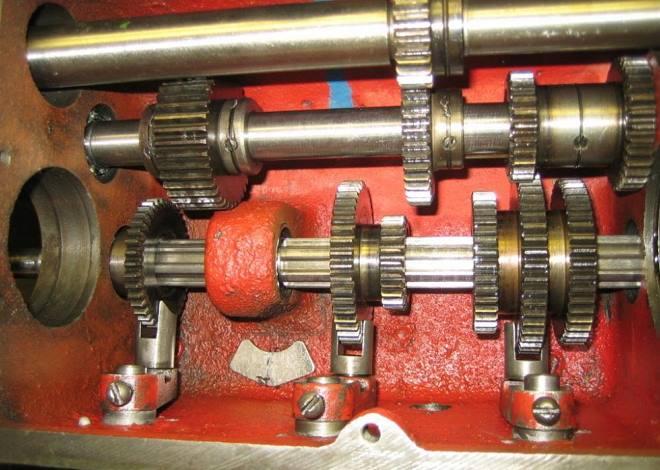

In order to transmit rotation from the gearbox of the gearbox unit, the transmission mechanism is used, also called a guitar. The main structural element of the guitar is the bracket, on which gears are mounted. Replaceable gears for the TV-6 machine are not provided, therefore the gear ratio, which provides a guitar, is constant and equal to ?.

Gearbox of the TV-6 machine

Features of TV-6 operation

Although TV-6 lathes are training, when working on them (if it is performed by a highly qualified specialist) it is possible to reach high accuracy and to carry out rather difficult turning operations. Due to such technical capabilities, these units are often purchased to equip home workshops.

The drive mechanism of the TV-6 lathe uses V-belt transmissions, which should be regularly checked for belt tension. This simple preventive measure will allow you to make the most of the power of the drive motor and significantly extend the life of the transmission. If the belt tension is loose, then it is easy to adjust. To do this, loosen the nuts, connecting sleds with drive motor, and set the required tension, which must be within 10 kg per branch of the V-belt.

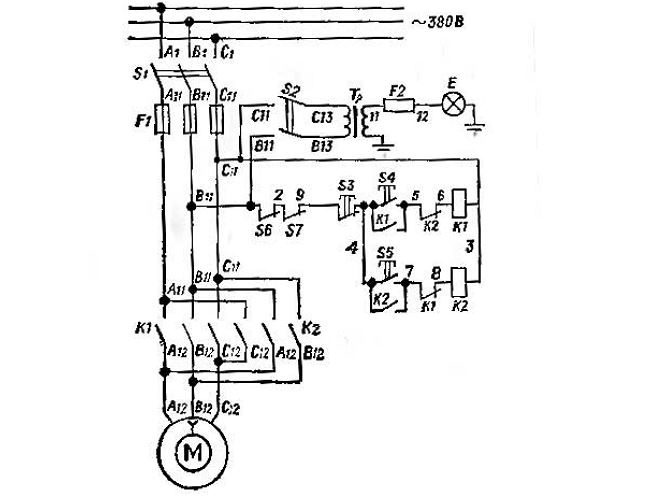

Wiring diagram TV-6

A fairly common malfunction of the TV-6 lathe is spindle vibration, which can be caused by loosening of the screw connections. If tightening of nuts of a spindle knot did not lead to weakening or elimination of such vibration, then, probably, it failed bearings, and this requires more qualified repairs.

If gaps are found in the spindle bearing assemblies, they can be eliminated by grinding the ends of the compensation rings or adjusting the nut and locknut. However, only small radial and axial gaps can be removed in this way.

The TV-6 model machine, like any other, needs regular maintenance and repair, which should be approached very responsibly. Only in this case you can count on it, that this equipment will last you a long time and will allow you to process parts with maximum accuracy.