Transparent plastic pipe. Areas of application, production

The range of pipe rolling is constantly changing. Example, today you can buy not only ordinary plastic and metal products in this industry, but also transparent pipes. For their manufacture is used as plexiglass, and the latest materials, example, polycarbonate. This substance is optically inferior to ordinary glass 1-2%, but is characterized by high strength and low specific gravity.

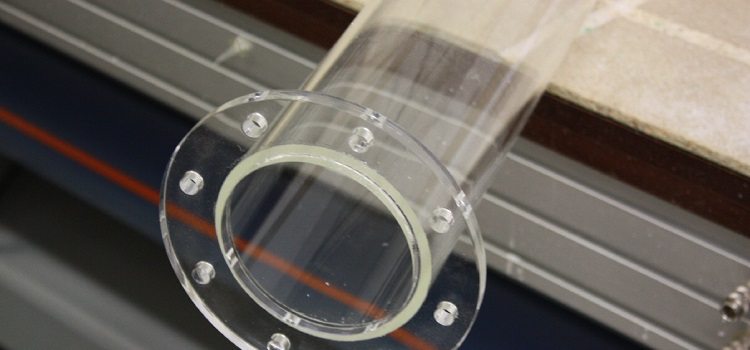

Transparent plastic pipes are made of different materials, but regardless of the raw material, products have high technical characteristics

Areas of application of plastic transparent pipes

Technical and operational characteristics of these products allow to use them in various spheres of human activity.

Medical and food industry. Transparent tubes provide an opportunity to monitor the supply of drugs and food with constant monitoring of their consistency. The material fully preserves the nutritional value of the product and its taste. The water transferred through a transparent plastic pipe remains primary pure. From the point of view of medicine it is very important, that the material does not react with drugs. The same property has determined the use of these products in the chemical industry. In particular, in laboratory devices, where visual control is especially important, what's going on.

Furniture industry. Here from transparent pipes from plastic details for furniture sets of modern style are made, interior accessories, exhibition stands, bar counters, trade counters, stair railings and more.

One of the options for using a transparent pipe is to make containers for various purposes for the food and medical industries

Advertising. In this area, they create a variety of lighting effects.

Materials for production

As raw materials for the manufacture of transparent plastic pipes are used, mainly, two materials. Let's dwell on them in more detail.

Plexiglas. Another name for this material is polymethylmethacryl (PMMA). It belongs to the group of thermoplastics. Popularity is due ??its unique optical properties. It? surface gloss in the absence of any image distortion. In such a plastic tube, it can be not only smooth, but also glossy or velvety. exept this, the transparent pipe from plexiglas gives in well to processing - cutting and drilling by the usual tool. And given the high impact resistance, products of this type are widely used in the manufacture of various equipment.

Useful Information! Externally, the surface of such pipes is brilliant polishing, while the inside has a matte hue.

Polycarbonate. The high demand for this material in industry and everyday life is due to ??the presence of such properties:

- high mechanical strength. In this respect, polycarbonate is superior to acrylic 10 times;

- lightness. Polycarbonate weighs about 2,5 times less, than glass.

Plexiglas is a material, easily processed, so working with pipes from it is quite simple

in addition, this material is respected by installers. The plastic transparent tube made of it can be processed by the simple carpenter's tool - to drill, cut, grind and you can screw a self-tapping screw into it without any problems.

Other advantages of such pipes include:

- well withstand temperature changes in a wide range. That is suitable for outdoor use;

- inertness to food (alcohol, drinking water, dairy products);

- resistance to detergents, solvents, acids and other aggressive compounds.

Technologies for the production of transparent pipes

For the production of acrylic (PMMA) transparent plastic tubes use two technologies - pressing and casting.

One way to produce transparent pipes requires the use of an extruder, this technology is also used for the production of other types of plastic pipe products

The extrusion process is performed by heating the plastic and then pushing it through an annular hole. The press is used for this purpose. Calibration is carried out in a special vacuum chamber. The future pipe is pressed against its walls by atmospheric pressure.

Production by casting technology includes the following stages:

- pouring plastic into a special mold, placed in a centrifuge;

- switching on this unit at the required number of revolutions. Under the influence of centrifugal force, liquid acrylic will be evenly distributed on the walls of the mold;

- the required product configuration is obtained after cooling the material.

Particular interest in such pipes is due to their transparency. They can be designed according to your preferences. However, the use of transparent pipes when creating a water pipe is not recommended. There are more practical analogues for this.