The machine for production of paving slabs by own hands

To start making large volumes of paving slabs, you will need a machine, it is easy to make with your own hands. Of course, it will be inferior to professional equipment, but still reduce production costs.

This design improves the quality of products and speed of manufacture

What is a professional machine

The standard device has the form of a complex installation. Despite the modest size, with its help organize not only the production of street tiles, but also establish mass production, that is, open your own business. In the second case, it is advisable to buy a ready-made device. This machine has five main parts:

- matrix;

- platform;

- capacity under the solution;

- vibrating installation;

- press.

The principle of operation is organized as follows:

- The mixture is put in the tank. It moves to the molds and through the bottom of the concrete is fed into the matrix.

- After that, the plates are superimposed on top and press the mass to the platform.

- Vibration is applied for better compaction and removal of voids. Fluctuations in combination with high pressure instantly seal the solution.

- After the form rises, and elements remain on the platform.

- Then they are removed together with the stand and dried.

The professional machine is intended for production of a strong street tile in large volumes

This design is made with their own hands, however, its capacity will be much less compared to professional equipment.

Devices for home production

To make quality paving slabs yourself, appropriate equipment must be prepared. Otherwise you will not reach the perfect state of concrete after pouring in the matrix.

The following devices are used in the production of standard products:

- vibrating table;

- pressing verstat;

- polyurethane molds for pouring.

The vibrating table can be improved and equipped with a clamping plate.

High-quality facing material is produced using a vibrating table

A person without design experience is unlikely to make such equipment without errors, but still worth a try.

How to make a vibrating press

The simplest option is to make a vibrating table. To design such equipment, will be needed:

- welding device;

- Bulgarian;

- drill;

- mounting bolts.

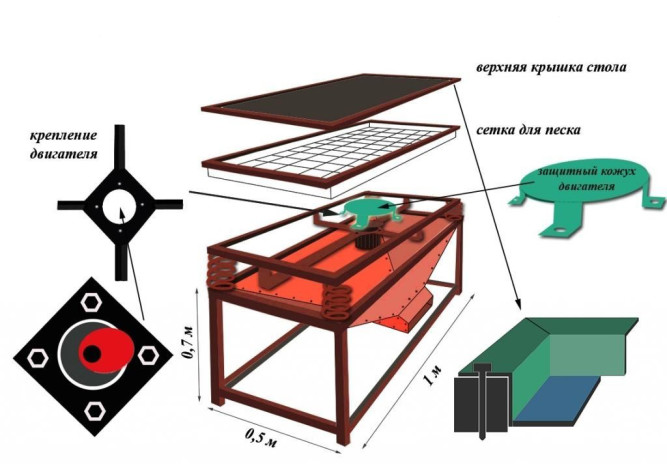

Preliminarily carefully process the drawings, to calculate the optimal position of the engine under the countertop. Then the framework from corners of 50х50 mm is welded and fixed on legs with plates in the bottom end face.. They will be needed, to lock the installation in one place. Then at the corners and in the middle fix strong metal springs. On them establish a flat table-top with sides. The engine is screwed in from below, example, from the washing machine.

Scheme of homemade vibrating table

An additional panel in the form of a flat cover is fixed on the vibrating table to arrange the press, she is under a lot of pressure. Individual elements are used, which are slightly smaller in size and are included, to compress the solution.

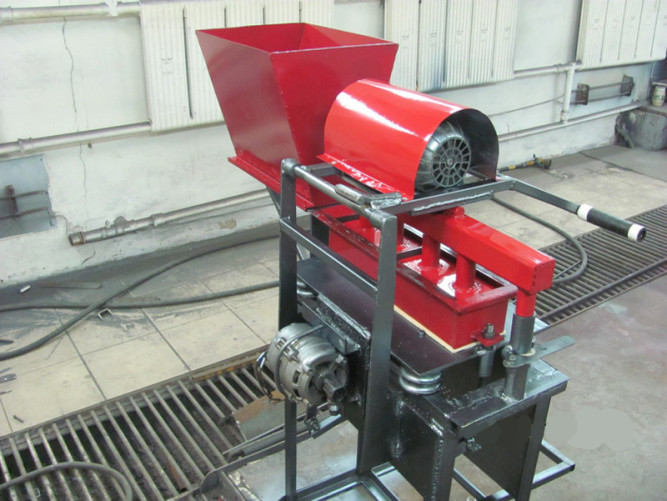

If you rely on the production model of the machine, then you will need a sheet metal profile. From the last the framework is welded. The container with the solution should look like a trapezoid, tapering downwards. The bottom folds down and provides supply of mix in a matrix, which are metal formwork and wooden slats. From above make a movable press from plates, included in the form of the clamping mechanism. Vibration is added to ensure the release of air. This option is used in the production of ordinary rectangular tiles.

It is not easy to assemble a full-fledged installation on your own, but possible

How to make shapes

If you want to make figured street tiles, you will need molds to pour the solution. You can make them yourself. Requires polyurethane with hardener and tile-sample or homemade element. It is made of plaster - the best option for creating figures of any complexity and configuration. The three-dimensional element is filled with liquid polyurethane. Since it mixes with the hardener, it will come out soft after a while, but a solid product, removed from the workpiece after complete drying.

Polyurethane prints every bend, recess or protrusion of the matrix, therefore, select reference samples as a template.

To ensure sufficient production volumes, will need at least 10 forms.

Краще купити готові поліуретанові матриці під розчин

Production recommendations

For full-fledged production of paving slabs, it is not enough to just buy the necessary equipment, it is important to follow the technology and take into account all the key points, related to this process:

- The machine with the press should give uniform uniform pressure on each centimeter of solution.

- Strong vibration disrupts the integrity of the mass and breaks the tile.

- Crushed stone and plasticizers are used in the preparation of concrete, increase the strength and elasticity of the solution.

- Cement grade should not be lower than M500.

- Before using the tiles, the blanks are completely dried, it usually takes at least a day. In order to speed up the process, special dryers are used.

- It is important to maintain optimal storage conditions in the production room: humidity, temperature, dust level, etc.. d.

- The equipment is regularly cleaned and checked for serviceability.

- When planning the mass production of products, you need to prepare the area for storage of products.

If you want to start a business for the production of paving slabs at home, it is better to buy factory equipment. And here for personal needs the machine, made with his own hands, - This is a very suitable replacement.