Starting the motor when using capacitors

If we turn our attention to all sorts of technology, used in our world, then we will find out, that it often uses asynchronous electric motors. That such electric motor often rotated, a mandatory rotating magnetic field is required. Such units are different:

- simplicity

- low noise

- good characteristics

- as well as ease of operation

That such a magnetic field was created, requires a three-phase network. In this case, it is enough to place the electric motor in the stator 3 windings, which will be placed at an angle of one hundred and twenty degrees relative to each other, then connect to them the necessary and appropriate voltage. It is then that the circular rotating field is able to rotate the stator.

In everyday life, devices that have only a single-phase electrical network are often used. The most common single-phase asynchronous motors in this field are used for such devices.

When we place the winding in the stator of the motor, then the magnetic field in it can be formed only specifically during alternating sinusoidal current. This field, however, cause the rotor to rotate, Unfortunately, can not. To start the engine , you need to do two things. Firstly, place an additional winding at an angle on the stator 90 degrees relative to the operating winding. And secondly, turn on the phase-shifting element directly in series with the additional winding. Such an element may be a capacitor.

Starting and working types of connection schemes

When you perform the necessary actions, a circular magnetic field will appear in the electric motor, accordingly, the corresponding currents will appear in the rotor. The interaction of current and stator field can cause the rotor to rotate. There are several ways to connect capacitors to an electric motor.

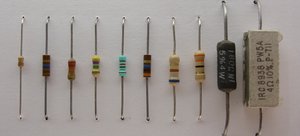

Depending on the method, there are different types of schemes. Can be used in these schemes, Firstly, starting capacitor, secondly, working capacitor, and at the same time the working starting condenser at once. The most common method is to connect with a starting capacitor.

Using a starting capacitor

When we start the engine, then the capacitor and the starting winding are switched on. This is due to this property, that the unit continues its rotation even in that case, when disconnecting the additional winding. For such start the relay and the button are most often used.

Because of that, that the start of a single-phase electric motor with a capacitor is quite fast, the auxiliary winding often runs for a very short time . Due to this, to save it, it is possible to make it from a wire with a relatively smaller cross section, than the main winding itself. To prevent and prevent overheating of the auxiliary winding, a thermal relay or a centrifugal switch is almost always added to the circuit. Thanks to these devices at a set by the electric motor of a certain speed or at achievement of strong heating it becomes possible regulating shutdown .

Scheme, which uses a starting capacitor has a fairly good starting characteristics of the motor, but the performance is deteriorating somewhat.

Advantages of the scheme with the working type of the element

You can get much better performance, if you use a circuit with a working capacitor. After starting the motor, the capacitor in this circuit does not turn off. Proper selection of a capacitor for a single-phase motor can provide great benefits. The main one is to compensate for field distortion and increase the efficiency of the unit. However, as expected, in such a scheme, the starting characteristics deteriorate.

It is worth considering as well, that when choosing the value of the capacity of the desired capacitor for the motor is made based on a certain load current. If the current changes relative to the calculated value, then, so, the field will change from a circular to an elliptical shape, as a result, the characteristics of the unit will deteriorate. To ensure high good performance, in principle, it is necessary to change the value of the capacitor capacity only when changing the load of the electric motor. However, this can make the switching scheme too complicated.

The most compromising solution is to choose a scheme, having starting and operating capacitors at the same time. In such a scheme, the starting and operating characteristics will be average compared to the previously discussed schemes. In general, if a large starting torque is required when connecting a single-phase motor, then in this case the scheme is selected specifically with the starting element. If there is no such need, then accordingly, the working element is used.

Here are some general tips for operation

When choosing a scheme, the user always has the opportunity to choose that scheme, which specifically suits him. However, of course, all the conclusions of the desired windings, the conclusions of the capacitor for the motor are displayed in the terminal box.

If you need to upgrade your system, and it is possible to do the necessary calculation of the capacitor for your used single-phase motor, then you can give advice. It is necessary to proceed from that, that for every kilowatt of power of your unit you need a guaranteed capacity 0,7 — 0,8 IFF for the working type or, in accordance, two and a half times the capacity of the starting type .

When checking the technical condition of the engine, you can often notice, that after a long period of work there was extraneous noise and unpleasant vibration. The rotor is difficult to check. The reason may be poor bearing condition. The treadmills were covered with horrible rust , scratches , dents . Some balls and the separator are damaged. In all these cases, you need to examine in detail and solve your problems. Yet, with minor damage is often enough:

- carefully and thoroughly wash the bearings with gasoline;

- then lubricate them;

- clean your engine case from dust and dirt.