Chimney diameter for gas boiler: features of calculation

Installation of a gas boiler is a serious event, which requires certain knowledge and skills. In addition to the installation of heating equipment, a very important point is to calculate the diameter of the chimney for a gas boiler. Properly selected dimensions of the chimney structure provide high-quality removal of combustion products outside the house.

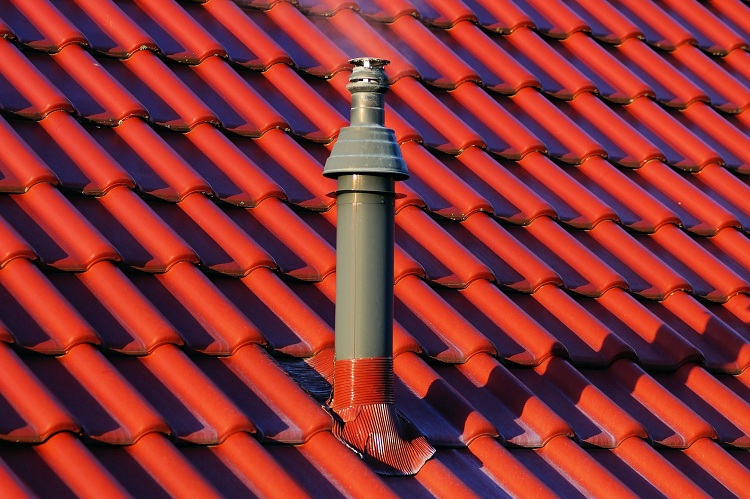

The size of the chimney for a gas boiler is selected depending on the power of the device

Which chimney is better for a gas boiler?

Pipes for the removal of combustion products of gas boilers can be made of different materials. Installation of heating and chimney requires compliance with construction rules and regulations, as improper installation of these structures can lead to an emergency. At once it is necessary to tell, that the temperature of the combustion products of such systems, usually, do not exceed the mark in 150 °C.

However, even in this case, the choice of material for flue communication must be taken seriously, since the products of gas combustion contain sulfuric acid. Sulfuric acid is an aggressive chemical compound, which corrodes the walls of smoke ducts of different materials, be it brick or stainless steel.

Council! To remove the products of combustion of gas boilers, experts recommend choosing structural elements for chimneys, which are made of acid-resistant steel grade (AISI 316L).

You should pay attention to another important factor - the dew point. The dew point is the limit of condensation in the chimney, which stops the combustion process in the heater. Such a point arises in that case, if there is a difference between the temperatures inside and outside the flue. This leads to the formation of a water plug, which prevents the removal of combustion products of the gas boiler. Brick structures are the most susceptible to this problem, since they have rough inner walls, contribute to the accumulation of condensate.

The best choice for a gas boiler are steel or ceramic chimneys

In the channels, mounted in stainless steel, the occurrence of a water plug is unlikely. The same applies to ceramic and asbestos-cement chimney pipes. However, asbestos-cement pipes when heated emit substances harmful to human health - carcinogens. The best option for the removal of combustion products of heaters, processing gas, are considered sandwich pipes. Such products consist of two pipes and a layer of thermal insulation between them.

Types of gas boilers

Not only the appearance of the heating structure depends on the type of boiler, but also its operational characteristics and features. To date, there are two main types of gas heaters. Consider them:

With open burner. Such equipment, usually, is mounted on the floor and has a fairly large capacity, which is higher 30 kw. The main difference between this equipment and the second type of gas boilers is, that oxygen is used to burn gas, which is indoors, where the boiler is installed. The open type of burner requires good ventilation of the room for normal operation. Therefore, buying a boiler of this type is recommended to take care of ventilation.

Insufficient ventilation of the working space will lead to the release of carbon dioxide during combustion, which endangers the lives of residents. To remove the combustion products of such a boiler, it is desirable to use a classic vertical flue. Such a vertical channel must be placed on the roof of the house, in which the boiler room is located.

For a gas boiler with an open firebox, the chimney is displayed vertically on the roof

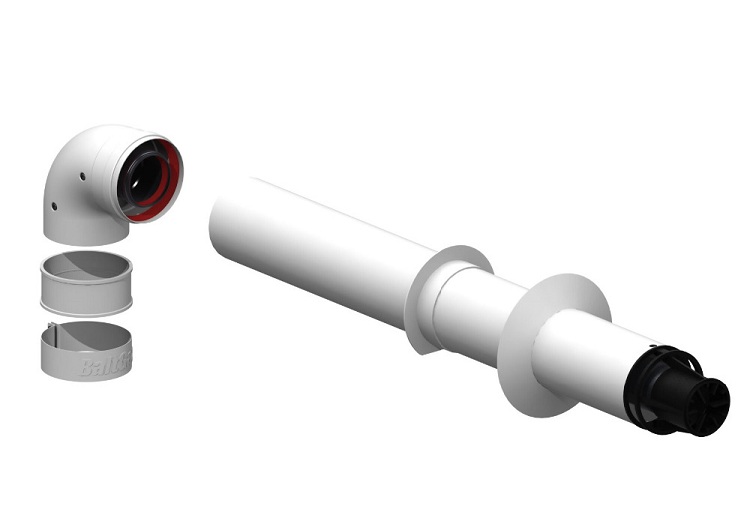

With closed burner. This type of burner is installed on heating equipment, characterized by low power (to 35 kw). In such boilers, fuel combustion takes place in a special sealed chamber. In this case, the gas output is possible only through the opening of the coaxial flue. Coaxial chimney is a modern technology, based on the specific design of the pipes. One of the pipes of such a chimney is located in the second pipe and has a smaller opening, but longer, than the second. The products of gas combustion move through the pipe with a smaller internal cross-sectional index, and on the second pipe there is a receipt of pure air in the heating device.

This heating structure operates due to special pumps, therefore it is energy dependent. Unlike vertical communication with a closed burner, such a system must be mounted in a horizontal plane..

Calculation of the chimney cross section for a gas boiler

First of all, you need to pay attention to one of the main indicators, on which the efficiency and efficiency of the flue depends. This indicator is the diameter of the chimney for a gas boiler. The calculation of the required cross-section of the channel in this case is carried out as a rule, which indicates that, what 1 kW of power of the heater is not less than, than 5,5 cm?.

Pipes from two heaters must be located at a distance from each other

Importantly! No more than two boilers may be installed for one residential building, located on different or on one tier.

Gas combustion products of two heaters, operating on gas and located on different tiers of the building, must enter the flue at a distance 50 cm (in height) one from another. This rule also applies to two heaters, located on one tier of the building.

Building codes do not prohibit the removal of combustion products from two heaters, operating on gas, in one chimney. However, in this situation, the cross section of the chimney is calculated from the total capacity of the units.

Other requirements when calculating the chimney

Consider other requirements, which must be observed when calculating the flue for a gas heater

- flue communication for the device, running on gas, should end in a vertically arranged pipe. This is a necessary rule for the normal removal of combustion products;

- in such communication a certain inclination is allowed (up to 30 °). The deviation of the flue communication to the sides should not exceed 1 m;

- indicator of cross-section of plots, located at an angle should in no case be less, than a similar parameter of vertical pipes;

- the cross-sectional area of the duct must not be less than or greater than the similar parameter of the exhaust pipe of the heater;

- chimney segment, located in the horizontal plane, must have a slope to the boiler (2 see on 1 m length of the channel);

- horizontally located segments of the flue must be equipped with viewing windows (audits);

- a tee connector must be installed at the lower point of the vertical communication, equipped with a hole for removing condensate;

- round chimneys have the minimum resistance and carry out the most qualitative removal of products of combustion of the gas heating equipment;

- the presence of chimney joints at the level of floor slabs is strictly prohibited;

- at the turning points of the system in the same way, as in the case of horizontal sections, inspection hatches must be installed.

It is important for the chimney not to have a lot of bends and turns, knees should be no more than three

pay attention! The maximum number of connecting elbows for flue communication is three.

Guided by the above rules, it is possible to execute high-quality installation of a flue design for the gas heating unit.

Chimneys of open gas boilers. What materials are used?

Different materials are used for installation of open gas boilers. For, to select a suitable material for the flue pipe, which will carry out the removal of combustion products of the gas boiler, it is necessary to get acquainted with their properties. Consider these materials:

- Brick. Brick chimneys are a real classic, however, for laying the flue of the gas boiler brickwork is the least advantageous solution. It has to do with that, that the inner walls of such a channel are rough and able to accumulate condensate, which causes corrosion of the chimney. There is one more minus - the brick smoke channels have insufficient tightness and are capable to pass products of combustion of gas.. In the case of brickwork, it is recommended to insulate the inner channel of the chimney with steel or aluminum sheets.

- Steel. Steel sheets for the interior of the chimney or pipe made of this material is a very reliable solution. It has to do with that, that steel of certain grades (316, 310S, 304, 316L) has good heat resistance and resistance to corrosion.

- Aluminum. This material is often used for this purpose, to perform the treatment of the inner surface of the exhaust communication, constructed of brick.

- Enameled pipes. Such products can be made at once with a heat-insulating layer on sandwich technology. From such enameled segments it is possible to mount the smoke channel without special effort, which will not require additional thermal insulation.

Choosing steel pipes, you need to prefer products with good heat resistance

Determination of the chimney cross section for an open type gas boiler

It is recommended to make a plan of future works before starting installation of chimney communication for open type gas boiler.. Determining the rectangular cross-section of the chimney is performed somewhat differently, than in the case of round structures. Consider the calculation of the correct cross section for both options:

- for rectangular communication, the cross section of the pipe is determined as follows: 1 kW of power must match 5,5 cm?;

- the indicator of round section of a flue has to be not less than diameter of an output branch pipe of the gas heating unit.

Importantly! When laying a chimney on a gable roof must be remembered, that the chimney should be above the highest element of the roof on 0,5 m. And if the roof is flat, then the channel must dominate its surface at least, than on 2 m.

Chimney communication, which is located vertically, must have a thermal insulation layer. Fire-resistant insulators are used for these purposes. Consider examples of fire-resistant insulation materials, which are perfect for this purpose:

- asbestos cement;

- brick;

- solution of lime and slag.

In addition to the mandatory installation of insulation, it is necessary to take care of the tightness of the structure. This is necessary for that, to prevent the penetration of combustion products into residential premises.

It is recommended to use a coaxial chimney for a closed gas boiler

Tips for proper chimney laying for a closed boiler

For closed heating device, running on gas, as mentioned above, special coaxial chimneys are used. The calculation of the cross-sectional coaxial chimney is reduced to one important rule: the cross section of the channel should not be less, than a similar indicator of the boiler outlet.

exept this, there are other rules, as well as provisions, which must be followed for the normal installation of the smoke channel of the coaxial type. Consider other rules for installing a coaxial smoke duct:

- you need to remember first, that the coaxial structure must be mounted in a strictly horizontal plane. Vertical mounting in this case is strictly prohibited;

- the distance from the coaxial chimney to the ground must be at least, than 2 m. Chimney, located below, will not function properly;

- minimum distance from windows, doors and openings, relating to ventilation communication, should be equal to 50 cm;

- vertical distance from windows, which are located above, must be at least 1 m;

- exept this, important to remember, that at a distance of one and a half meters from the coaxial smoke channel, there should be no obstacles. Obstacles in this case may be: pillars, fences, walls, etc.. d.;

- it is strongly recommended not to install smoke ducts in the arches, tunnels and transitions, which are located underground;

- do not forget about the required slope of the coaxial pipe. This slope ensures the removal of condensate from the structure and, usually, is from 6 to 12 degrees.

Proper installation of the gas boiler chimney is the key to long and safe operation of this equipment. The size of the chimney for any gas boiler is the main characteristic, which includes a number of parameters, which are determined in fairly simple ways. However, for reliability, it is recommended to consult a specialist, who are able to perform these calculations, pick up materials and mount a quality system from them.