Connection of metal-plastic pipes with fittings during plumbing installation: features of work

The popularity of metal-plastic pipes with the advent of polypropylene counterparts has declined slightly. However, even today they occupy a large niche in the plumbing market. Example, when equipping a heated floor there is no worthy replacement of metal-plastic pipe products. From metal these products received durability, and from plastic flexibility. The right approach to the connection of metal-plastic elements will save a considerable amount when installing the pipeline.

Installation of metal-plastic pipes is often carried out by a special type of fittings

Design and characteristics of metal-plastic pipes

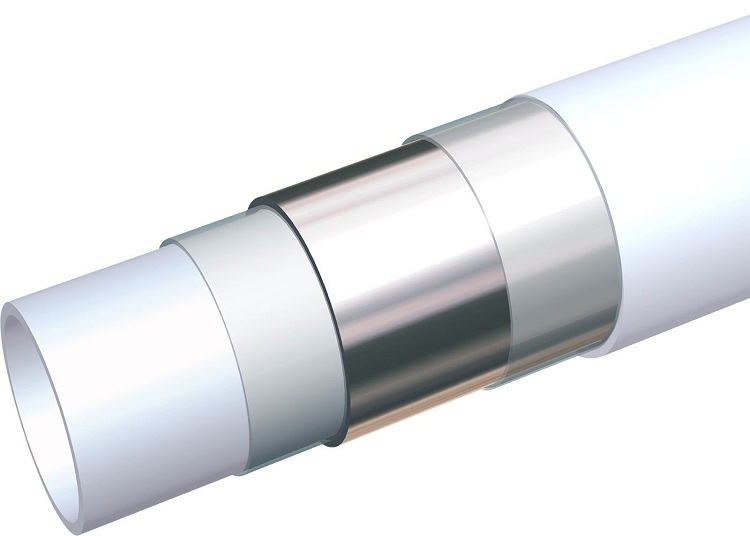

The inner and outer parts of these products are made of plastic, due to which the design has a high resistance to negative factors. Between these parts is a reinforcing layer, which is an aluminum foil. Glue is applied on both sides. It securely fixes it between the plastic layers. On the one hand, such a device provides flexibility of the product, but multiple inflections in one place are not allowed.

The reinforcing layer is overlapped by ultrasound or laser butt. Pipe products with a connection according to the first option are characterized by uneven geometric parameters, and for this reason it plays in strength. Ware, butt welded using laser technology, called seamless. They have a uniform thickness along the entire length, more reliable, but also cost more.

Aluminum layer on the main operating parameters of the pipeline impact, practically, does not do anything. Her tasks are as follows:

- providing partial compensation for the expansion of the polymer when heated;

- creating a diffusion barrier, which prevents oxygen from entering the pipe.

Because the movement of the liquid is carried out on a plastic layer, that is why it forms the performance properties of metal-plastic pipe products.

Useful to know! Both layers - inner and outer - are made of cross-linked polyethylene. And for the metal-plastic water supply system an expensive type of this polymer is used - food polyethylene, and for the sewer pipeline cheaper.

Metal-plastic pipe is a multi-layered product, inside which is a reinforced layer

Water hammer systems can occur in water supply systems. Pipe products cope with them perfectly, marked with such sequences of characters: PEX and PE-RT. And here for the arrangement of branches of a water supply system, in which the probability of water hammer is high, from metalplastic pipes with PE-RS marking, PE-HD and HDPE are better to give up - they work at low pressure.

Among the advantages of these products should be highlighted:

- ease of installation;

- high chemical resistance;

- environmentally friendly materials are used for production;

- flexibility makes it possible to bypass inequalities and angles, which in some cases reduces the relevance of the connection of metal-plastic pipes with fittings in a limited space. They can simply be bent;

- no scale is formed on the inner surface;

- not prone to corrosion;

- long service life - up to 50 years.

But there are also shortcomings. The main ones are as follows:

- exposure to ultraviolet light causes "aging" of metal-plastic pipe products;

- such products are prone to burning.

How to connect metal-plastic pipes correctly

Special press fittings are used to connect these elements of the water supply branch, compression parts and sliding press fittings. Consider the method of their installation in more detail.

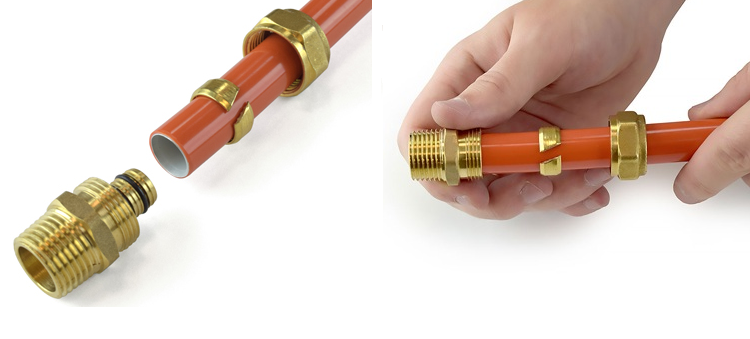

Compression fittings are convenient and easy to operate, they can be used more than once

Compression parts. In this case we are talking about the use of crimp brass fittings. To connect the elements of the water supply branch with their help, enough to have a wrench. The design of the part includes a cap nut, fitting and split ring. Crimp fittings can be disassembled, and reuse.

Even a man, who has only basic plumbing skills, can cope with the task of connecting metal-plastic pipes with this technology. The sequence of measures is as follows:

- first a pipe of the required length is prepared. The basic requirement sounds like this: the area of the workpiece at a distance 10 cm before and from the incision site should be smooth;

- then the workpiece on the marking is cut with precision scissors. The plane of the cut must be strictly perpendicular to its longitudinal axis;

- after checking the integrity of all parts and gaskets, a nut is put on the pipe, and then the ring from the fitting;

- the edge of the workpiece is processed by scanning. The calibration side removes the inner chamfer on 1 millimeter. The other side is the outer chamfer;

- the pipe is placed on the fitting until it stops;

- the union nut is screwed on the union at first manually, and then with the key. Ultimately should remain in mind 1-1,5 thread turn.

Advice! Tighten the nut very carefully. Excessive force may cause the ring to crack.

This factor determines the presence of one feature of such collet connection of metal-plastic pipes. It consists in the need to periodically tighten the cap nut.

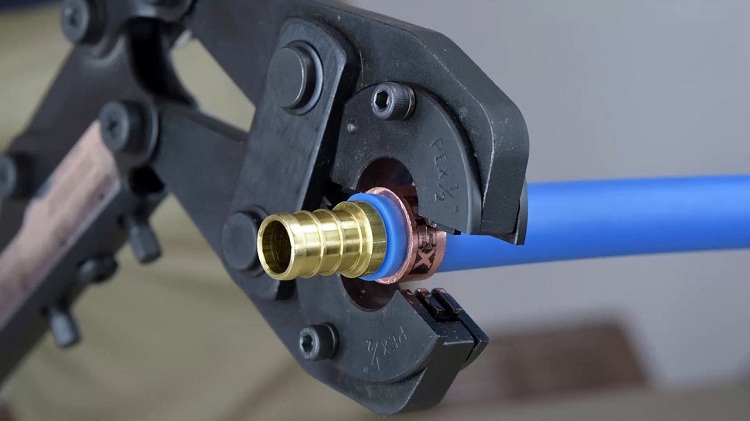

If there is a need for concealed piping, then press fittings should be used for their installation

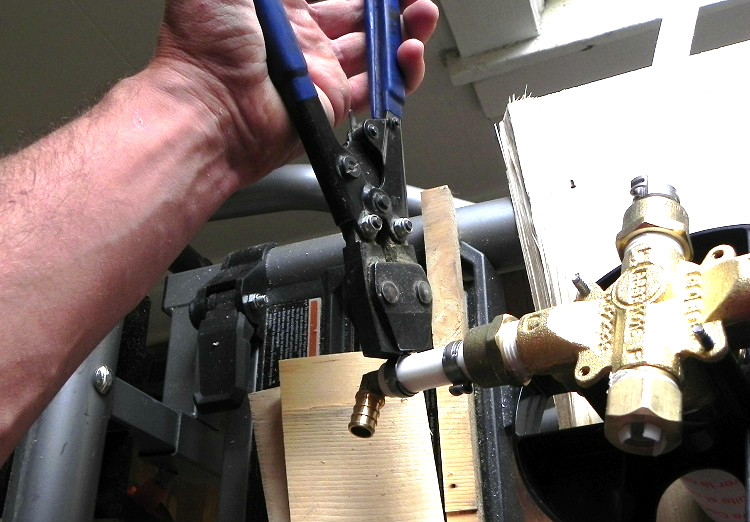

Special press fittings. These connecting elements are used when laying concealed communications and when installing underfloor heating. The work is carried out using a tool, which is called press ticks. Installation in this case is more reliable, than when using compression fittings. The connection is as follows:

- the pipe is cut. The edge is calibrated by removing the chamfers, as external, and internal. Control of diameter of a pipe is carried out by means of the calibrator;

- the fitting is checked for the presence of sealing rings and a dielectric gasket;

- a crimp sleeve is put on its edge;

- rings of seals are put on the union, then the fitting is inserted into the pipe;

- in the process of crimping the coupling with the help of press pliers it is necessary to control the penetration of the flange of the sleeve into the recess on the press nozzles. This tool is equipped with inserts, suitable for working with pipe products of different diameters. It is undesirable to crimp the coupling again, it is necessary to act so, that a positive result came out the first time.

Press fittings are on sale, the coupling on which is already fixed. This technical solution allows you to immediately put the part on the pipe. The planting depth is controlled through the hole in the coupling.

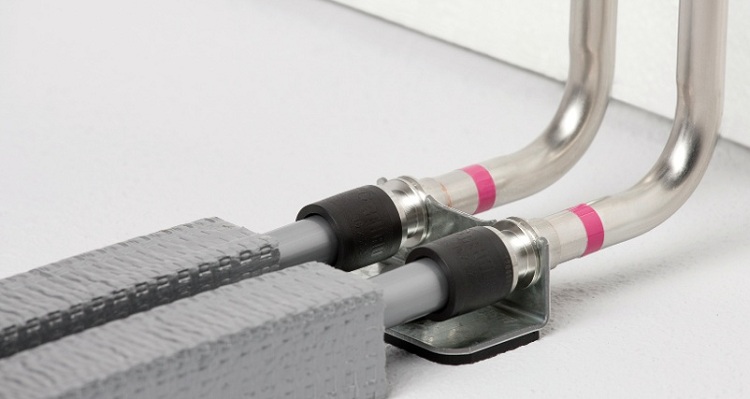

Sliding fittings. This connector for plumbing metal-plastic pipes is fixed not only with the help of press pliers. In this case, it is also envisaged to use an expander to expand the diameter of the pipe to size, that allows to carry out reliable fastening of a fitting. The result is an inseparable connection. Use it when installing a hidden pipeline.

Sliding fitting provides an integral connection, and can also be used for concealed wiring

Answer to the question, how a metal-plastic pipe is connected to a fitting of this type begins with a standard phrase: first prepare a segment of the required length. Then put the clutch on it, then the edge of the pipe is expanded with an expander. Then the fitting is put on, the coupling is clamped by a press, and the fitting on the fitting is tightened. Doing so will ensure a secure and tight connection.

How to connect metal-plastic pipes to metal pipes

The need for this operation arises, When, example, only a part of a water supply system changes or if the metalplastic branch is deduced from a metal riser. It is important to follow the step-by-step instructions. The most common option is to use a crimp fitting.

Perform the work in the following sequence:

- if the pipe is old, clean it of rust, and screw the fitting on it, using a wrench.

Advice! To prevent leakage, the tested method will approach: impregnate the tow with paint and wind the resulting sealant in a thin layer on the pipe thread, then screw on the connector.

- while the paint dries, work with metal-plastic pipe product: pull it through the nut and press washer, and calibrate the pipe itself;

- then screw the cone to the metal pipe and put the metal-plastic pipe product on it;

- tighten the nut with a wrench, having achieved that, to compress the washer tightly to the metal-plastic pipe element.

Connection of metal-plastic pipes with radiators

To perform this procedure, several schemes have been developed using fittings and special adapters.

- When the pipeline is laid in the floor by the method of hidden wiring, bottom-down scheme used. The presence of valves and thermostats requires the use of special adapters, designed to secure all necessary connections.

There are fittings, that allow you to connect metal and metal-plastic pipes

- Adapters and are also used for side connection, in addition, tees - brass or chrome with metric thread.

- Connection to the floor exit. Complicates the implementation of this scheme "running" of the front pipes. This phenomenon effectively compensates for the telescopic fitting.

- Diagonal or angular connection scheme. This method is not the only one that exists, implementation of which requires the use of swivel knees.

Installation of metal-plastic pipes. Tips from professionals

One of the great advantages of this pipe product is the ability to create shaped elements from it, change the direction of the pipe to any desired angle, not to mention that, that under certain conditions it is possible to fold even in a ring. When installing a metal-plastic pipe, professionals recommend using a collector. This approach will ensure uniform pressure of water flow to all connected consumers. You should also listen to another piece of advice from plumbers, behind whose shoulders a long experience of work. It sounds like that: to minimize the number of connections and, in accordance, to increase system reliability, the pipe from the collector to the end consumer is better to use "one thread".

To bend pipe products from metalplastic it is necessary with use of a pipe bender or a manual conductor, which is a spring. It can be worn on top or placed in a pipe.

Advice! It is better to use the internal conductor at production of small shaped elements. Then this accessory will not slip through, that the contractor controls the bending stress of the pipe and, in accordance, conductor with his own hands.

Installation of structures made of metal-plastic pipes must be carried out according to all the rules, otherwise the system will be unreliable

You can't do without an external conductor if you need to create turns or several turns of the pipeline (example, when laying a warm floor). If you do not have the skills to work with metal-plastic pipes, it is not recommended to bend these products only with your hands without tools.

pay attention! In the best case, you will narrow the cross section of the branch of the water supply, and at worst - just break the pipe at the bend.

Returning to the conversation about the connection of metal-plastic pipes with fittings should be noted, that pipelines, laid in the floor or in the wall, are equipped with integral maintenance-free parts. The same ones, which go openly, it is allowed to equip with any convenient combination. The use of compression fittings is advisable when connecting, example, taps and other plumbing fixtures. This will ensure their quick repair or replacement.

Fixed and movable supports are used for fastening of pipelines to a wall. They are made of plastic of any kind, example, polyvinyl chloride. Having decided to use similar metal accessories, equip them with an elastic gasket. Supports must not cause deformation of the pipe or its outer layer. Laying a branch of water supply in an open way, use detachable supports.

How to disassemble the fittings of metal-plastic pipes

It should be noted immediately, that not all types of connections can be replaced with new connectors without damage. It all depends on the technology used to connect the metal-plastic pipe products, example, which fittings were used when performing this procedure for specific sections of the pipeline.

If the connection was made using press fittings or fittings with sliding couplings, subjected to pressing with press tongs, such compounds belong to the category of non-demountable. Therefore, if necessary, their replacement is performed by complete dismantling followed by cutting off this section of the pipeline. Then you will need a new set of fittings and also an additional piece of pipe.

If a compression-type connector was used for metal-plastic pipes, you only need to unscrew the clamping nuts, which is quite simple. And so it will not be difficult to disassemble the whole area with a problematic connection.

The choice of fittings for such pipe products must be approached with great care. It is better to prefer products from well-known companies. After all, the most common cause of all accidents and leaks - poor quality connecting elements of metal-plastic pipelines.