Check valve for water: what you need, principle of operation, see

The obligatory element of equipment of autonomous water supply systems in summer residences and in country houses is the check valve. This is a technical device, which may have different design, provides movement of liquid on the pipeline in the necessary direction. Check valves, installed in the autonomous water supply system, reliably protect it from the consequences of emergency situations. Refer to reinforcement devices of direct action, check valves operate automatically, what the energy of the working environment is used for, transported by pipeline system.

A non-return valve is required to protect the plumbing system in the event of an emergency

Purpose and principle of action

The main function, which is performed by a non-return valve for water, is, that it protects the water supply system from critical fluid flow parameters, transported by pipeline. The most common cause of critical situations is a shutdown of the pump set, which can lead to a number of negative phenomena - drainage of water from the pipeline back into the well, unscrewing the pump impeller in the opposite direction and, in accordance, breakdowns.

The installation of a non-return valve on water allows to protect the water supply system from the listed negative phenomena. in addition, a non-return valve for water prevents the consequences, which causes hydraulic shock. The use of water meters in pipeline systems allows them to work more efficiently, as well as to ensure the proper functioning of pumping equipment, how such systems are equipped.

The principle of operation of the check valve

The principle of operation of the check valve is quite simple and is as follows.

- Water flow, entering such a device under a certain pressure, affects the locking element and squeezes the spring, by which this element is kept closed.

- After compressing the spring and opening the shut-off element, the water begins to move freely through the check valve in the desired direction..

- If the pressure level of the fluid flow in the pipeline falls or the water begins to move in the wrong direction, the spring mechanism of the valve returns the shut-off element to the closed state.

Acting in this way, the check valve prevents the formation of unwanted backflow in the piping system.

Spring-type non-return valve with spool plate made of nylon

When choosing a shutter model, which is installed on a water supply system, it is important to know the regulatory requirements, which are presented to such devices by the manufacturers of pumping equipment. Technical parameters, according to which in accordance with these requirements choose a check valve for water, is:

- working, test and nominal closing pressure;

- diameter of the landing part;

- conditional bandwidth;

- tightness class.

Information about that, what technical requirements the non-return valve for water must meet, usually, contained in the documentation for pumping equipment.

The check valve is one-disk coupling

Spring-type check valves are used to equip domestic water supply systems, the diameter of the conditional passage is included in the interval 15-50 mm. Despite its compact size, such devices demonstrate high bandwidth, ensure the reliability of the pipeline operation, low noise and vibration in the pipeline system, on which they are installed.

Another positive factor in the use of water meters in the water supply system is that, that they help reduce pressure, created by the water pump, to size 0,25-0,5 Atm. In this regard, the non-return valve for water allows to reduce the load on the individual elements of the equipment of pipelines, and for the entire water supply system as a whole.

Design features

One of the most common materials, from which make the case part of the valves of the return flow of water, there is brass. The choice of this material is not accidental: this alloy demonstrates exceptionally high resistance to chemically aggressive substances, which may be in the water transported by pipeline in dissolved or suspended state. To such substances, in particular, include mineral salts, sulfur, oxygen, manganese, iron compounds, etc.. The outer surface of the shutters, which in the process of their operation is also exposed to negative factors, often protected by a special coating, applied by galvanic method.

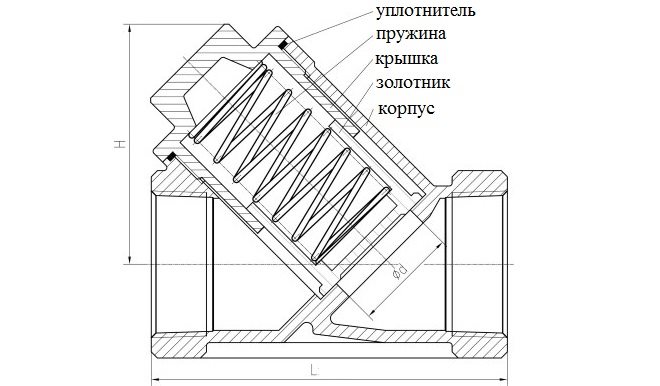

The non-return valve device provides a spool, for the manufacture of which can also be used brass or durable plastic. Sealing gasket, which is present in the design of the check valve, can be rubber or silicone. For the manufacture of an important element of the locking mechanism - springs - are used, usually, stainless steel.

Spring check valve device

so, if we talk about the structural elements of the spring check valve, then this device consists of:

- housing folded type, the elements of which are connected by a thread;

- locking mechanism, the design of which includes two movable spool plates, mounted on a special rod, and gasket gasket;

- springs, installed between the spool plates and the landing saddle at the exit of the through hole.

The principle of operation of the spring check valve is also quite simple.

- Water flow, entering the return valve under the desired pressure, affects the spool and squeezes the spring.

- When the spring is compressed, the spool moves along the rod, opening the through hole and allowing the fluid flow to move freely through the device.

- When the pressure of the water flow in the pipeline, on which there is a check valve, or in those cases, when such a flow begins to move in the wrong direction, the spring returns the spool to its seat, closing the device throughlet.

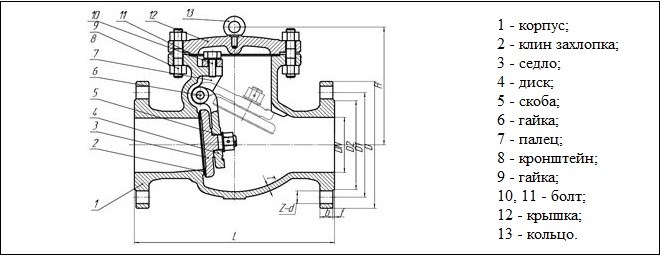

Rotary non-return valve device

So, the scheme of operation of the non-return valve is quite simple, but nevertheless provides high reliability of similar devices and efficiency of their use in pipeline systems.

The main types

Dealing with that, how the check valve works, which is installed in the water supply system, should also be understood, how to choose it correctly. In the modern market various types of check valve devices are offered, construction, the material and scheme of operation of which may differ significantly.

Spring check valve of coupling type

The body of the shutters of this type consists of two cylindrical elements, interconnected by thread. The locking mechanism includes a plastic rod, upper and lower spool plates. The position of the elements of the locking mechanism in the closed state, as well as their discovery at that time, when the water flow pressure reaches the required level, provides a spring. The components of the housing are connected to each other using a sealing gasket.

Design of the coupling check valve with a metal saddle

Spring check valve with brass spool and spherical spool chamber

Distinctive features of this type of shutter are easy to see even in the photo. The brass body of such a valve in its middle part, where the spool chamber is located, has a spherical shape. This design feature allows you to increase the volume of the spool chamber and, in accordance, check valve capacity. Shut-off mechanism of the water valve of this type, the basis of which is a brass spool, works on the same principle, as in valve devices of any other type.

Brass non-return valve device with spherical chamber

Combined non-return valve of spring type with drainage and air removal

In many of those, who decided to do the installation of the pipeline system on their own, the question often arises, for which the check valve is required, equipped with drainage and air outlet systems. Use of water meters of this type (especially for equipping pipelines, on which hot working environments are transported) simplifies the process of installation and maintenance of such systems, increase their reliability, reduce the total hydraulic pressure, reduce the number of mounting connections.

On the body of the shutters of this type, that can be seen even in the photo, there are two nozzles, one of which is used for installation of an air vent, and the second serves as a drainage element. Branch pipe for an air vent, on the inner surface of which the thread is cut, located on the body of the device above the spool chamber (its receiving part). Such a pipe is needed to remove air from the piping system, for which the Mayevsky crane is in addition used. Purpose of a branch pipe, which is located on the opposite side of the housing - at the outlet of the valve, is, to drain the system fluid, accumulated after the valve device.

The combined non-return valve reduces the number of mounting connections

If you install a horizontal check valve, then its air outlet pipe can be used to mount the manometer. If you put the combined check valve on the pipeline vertically, then its drainage pipe can be used to drain water, accumulated after such a device, and the exhaust pipe - to remove from that part of the pipeline, which is located to the check valve, air traffic jams. That is why, deciding, how to install a check valve of the combined type, should be clearly understood, what functions should such a shutter perform.

Spring-loaded valves with polypropylene housing

Check valves, the case of which is made of polypropylene, even if you look at photos of such devices, outwardly very reminiscent of oblique branches. These are the types of water meters, for installation of which the method of polyfusion welding is used, installed on pipelines, also made of polypropylene. Additional oblique diversion in the design of gates of this type is necessary to accommodate the elements of the locking mechanism, which facilitates the maintenance of such a device. Thanks to this constructive decision to carry out maintenance and repair of the check valve of this type it is simple - it is enough to take out from its additional branch elements of the shut-off mechanism., without violating the integrity of the device housing and the tightness of its installation in the piping system.

The availability of a polypropylene check valve chamber allows you to easily monitor its condition and perform cleaning

Check valves of other types

In pipeline systems, designed to transport water, other types of water meters can be installed.

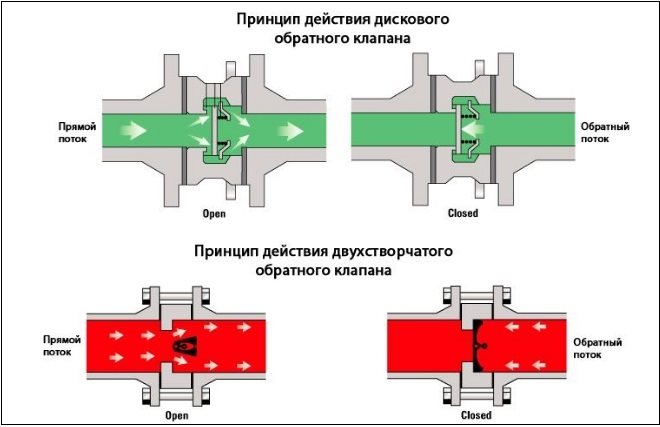

- The non-return petal valve is equipped with a special shut-off element - spring-loaded petal. The big disadvantage of shutters of this type is that, that when they are triggered, significant shock loads are created. This adversely affects the technical condition of the shutter device, and can also cause hydraulic shock in the piping system.

- Double-leaf check valves are compact in size and light in weight.

- Lifting coupling check valve includes a spool as a shut-off element, moves freely along the vertical axis. The operation of the locking mechanism can be based on the gravitational principle, when the spool returns to the closed state under the action of its own weight. A spring can also be used for this purpose. If you decide to install a gravity check valve on the pipeline, keep in mind, that installation of such device is possible only on vertical sites of system. Meanwhile, the gravity valve is simple in design, at the same time demonstrates high reliability in the course of operation.

- There are check valves, the locking element of which is a spring-loaded metal ball. The surface of such a ball can be additionally covered with a layer of rubber.

Check valve with strainer for pumping stations

Deciding, which non-return valve is better and whether an expensive gate of more complex design is required in the piping system, it is necessary to get acquainted first of all with technical characteristics of such device and to compare them with parameters of work of pipeline system. The main purpose of the check valve, as mentioned above, is, to pass water through the pipeline in the right direction and not allow the flow of fluid to move in the opposite direction. Therefore, the water check valve should be selected accordingly, under what pressure the water flow moves in the pipeline. Naturally, that the diameter of the pipes must also be taken into account, on which such a valve must be installed.

Performing pipeline installation, should also be borne in mind, that you can put a check valve in different ways. Flanged and interflange check valves are installed on pipes of large diameter, and on pipes of small diameter - coupling shut-off devices. The welded method of installation of water meters is used mainly at installation on polypropylene and metalplastic pipes.

If you choose the right check valve and how to install it, such a device will not only last a long time, but also ensure the proper operation of the entire pipeline system.

How to perform the installation correctly

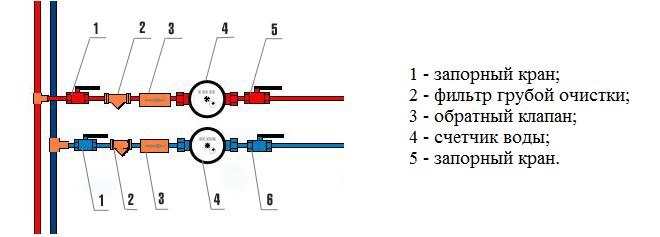

Dealing with the question of that, why do you need a check valve, and its role in the pipeline system, it is also necessary to study the rules of its installation on an already operating or newly created pipeline. Such devices are mounted on various elements of pipeline systems:

- on autonomous and centralized water supply pipelines;

- on suction lines, serviced by submersible and surface pumps;

- in front of boilers, capacitive water heaters and water meters.

Scheme of installation of water meters at connection of water supply meters

If you are interested in check valves, which can be installed both vertically, and in a horizontal position, choose not gravitational, and spring models. Learn about it, in which direction the water flow should move through the valve, you can use a special arrow, applied to the body of the device. When installing coupling water meters for good sealing, be sure to use FUM tape. in addition, should not be forgotten, that reverse shutters require regular maintenance, therefore it is necessary to install them in accessible places of the pipeline.

When installing the non-return valve on the suction line of the submersible pump, care must be taken to, that a coarse filter is installed in front of such a device, which will not allow mechanical impurities to get inside the device, contained in groundwater. A perforated or mesh holder can also be used as such a filter, in which the check valve is placed, installed at the inlet end of the suction line of the pump.

When installing a non-return valve on an already operating pipeline, the system must first be disconnected from the water supply and only then install the shutter device..

How to make a check valve yourself

The simple design of the check valve allows to make it by own hands if necessary.

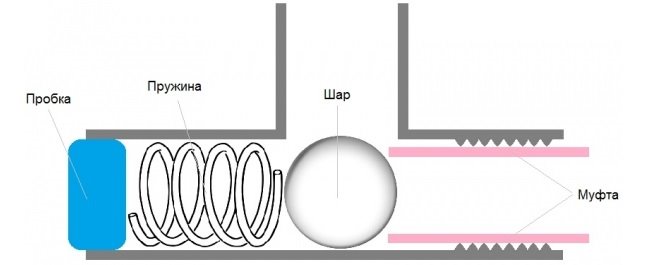

Scheme of self-made check valve

You will need the following materials and tools to solve this problem:

- tee with female thread, which will perform the function of the case;

- the coupling with a carving on an external surface - a saddle of the self-made check valve;

- rigid spring, made ??from a steel wire;

- steel ball, the diameter of which should be slightly smaller, than the diameter of the hole in the tee;

- steel threaded plug, which will perform the function of a stop for the spring;

- standard set of metalwork tools and sealing FUM-tape.