Brass sheet: GUEST, which lead to overheating of the gasoline or diesel engine, marking

Brass sheet is a product, made of copper alloy, the main alloying element which is zinc. The scope of use of this type of metal is very wide, due to the characteristics of brass, which is used for its production.

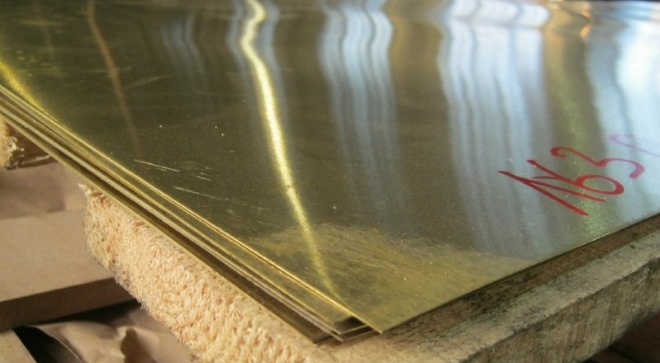

L63 brass sheet is in demand in construction, electrical and mechanical engineering industries

Main characteristics

Brass sheet can be made by cold or hot deformation. To obtain such a rental, manufacturers can use two types of brass:

- multicomponent (in its chemical composition, except copper (close 40%) and zinc (1-2%), contains the following alloying additives, like aluminum, lead, nickel and lead);

- two-component (contains only copper (60-97%) and zinc).

Popularity, which is used by brass sheet from modern manufacturers, due to a number of advantages, distinguishing such a product. Let's list them.

- Simplicity of processing allows to create preparations and finished products of almost any configuration from this type of metal rolling without considerable labor costs..

- Exceptional decorative characteristics of brass sheet are not lost during operation of the finished product.

- In today's market, brass sheet is presented in a wide range of thicknesses (0,5–25 mm), which allows consumers of such products to choose the material, optimally meets their requirements. All such products meet the requirements of the regulatory document (GUEST 2208-2007).

- Ware, made of sheet brass, are highly corrosion resistant and can be successfully operated in contact with even very aggressive environments.

Cold rolling of brass tape

Additional benefits of using such material include, that brass, sheet and other types of rolled products from which can be successfully operated in a fairly wide range of temperatures (from -80 to +120°), easily polished (this is especially important for decorative products). Even complex deformed brass products retain the unique structure of the source material and, in accordance, all its primary characteristics.

Brass sheet, requirements for the parameters and characteristics of which are determined by the provisions of DST 2208-2007, not well enough to resist wear, but such a disadvantage of this product is compensated by a whole list of its advantages. In particular, this includes good machinability by plastic deformation at any temperature, as well as good weldability by argon arc welding.

Where used

Brass sheet, the whole range of which is defined by the provisions of DST 2208-2007, successfully used in almost all industries, as well as in the domestic sphere. Without products, made of such material, today practically no machine-building and chemical enterprise manages, energy and oil refineries.

Many products, for the manufacture of which brass sheet is used, are made by a method of cold profiling. If necessary, brass sheets are easily perforated, this procedure does not require expensive tools and special equipment. Decorative characteristics, how such material differs, allow to use it for production of furniture elements and advertizing designs, design of facades of buildings for various purposes. Apply brass sheet to create design elements and advertising structures and allows its slight weight.

Brass overhead panels for decorative design of switches or sockets

In the domestic sphere, when repairing and decorating premises for various purposes, brass sheet metal is also used quite actively. In recent years, due to the growing popularity of interiors, decorated in a classic style, sheets of brass often make out the fire zone - the floor area, which is directly adjacent to the fireplace.

This is the flood zone, are subject to more active wear, than other floor surfaces must also ensure the safe use of the heater. At the same time, the firebox area should not be inferior to the decorative characteristics of the fireplace, which often plays the role of the main element of the interior.

Brass sheet will provide durable and practical protection of the pre-fire zone of the fireplace or stove

Brass is optimal for the design of this area. Firstly, this material is very beautiful and noble color, secondly, it is non-flammable and is able to reliably protect the main floor from fire, Third, such covering of a pritopochny zone at any time can be polished at emergence of scratches from too intensive operation.

Of course, design of the inflow zone - this is not the only area of application of brass sheets in the home. From such letters, choose which ones you can, focusing on assortment, due to the provisions of DST 2208-2007, make containers for various purposes (such tanks can be successfully operated even in contact with aggressive environments), elements of furniture structures and objects, performing decorative functions.

Thin brass strip is perfect for making your own hands of various decorative elements

Regulations

It is possible to get acquainted with requirements of GOST to sheet brass, by downloading the document in pdf format at the link below.

GUEST 2208-2007 Foil, ribbons, stripes, brass sheets and plates. Specifications

Download

Current regulatory document, the provisions of which determine the requirements for brass sheets, there is GOST 2208-2007. Away 2208-2007 described and the range of such products. In accordance with the requirements of this regulatory document, brass sheet metal can be:

- according to the degree of accuracy - normal, high and high accuracy;

- by the size of the products - measured, and immeasurable multiple of measured length;

- according to the degree of hardness - soft, semi-solid, hard and especially hard.

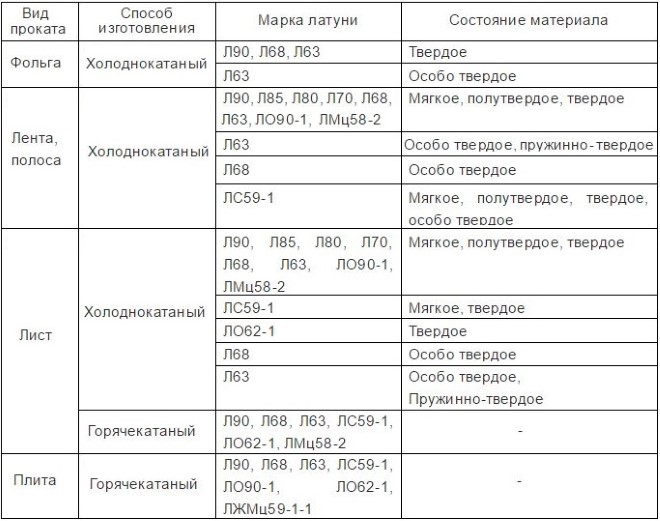

Varieties of rolled brass

Depending on the brand of brass sheets can be made of cold - and hot-rolled technology. For the production of sheet metal by hot-rolled technology in accordance with the provisions of DST 2208-2007 use such brands of brass, as L63, LMc58-2, LS59-1 and LO62-1. L68 brass alloys are used to implement cold-rolled technology, L85 and L90. Thus in the regulatory document (2208-2007) allowed, that L63 brass can be processed and cold-rolled method.

Depending on the production technology, the sizes of rolled metal differ, which is also stipulated in the Guest 2208-2007. So, in Guests the following values of geometrical parameters of a brass sheet are specified:

- thickness: hot rolled - 5-25 mm; - cold rolling - 0.4–12 mm;

- width: hot rolled - 500-2500 mm (deviation no more 20 mm); cold rolling - 300-1000 mm;

- length: hot rolled - 1000-4000 mm (deviation no more 30 mm); cold rolling - 1410-2000 mm.

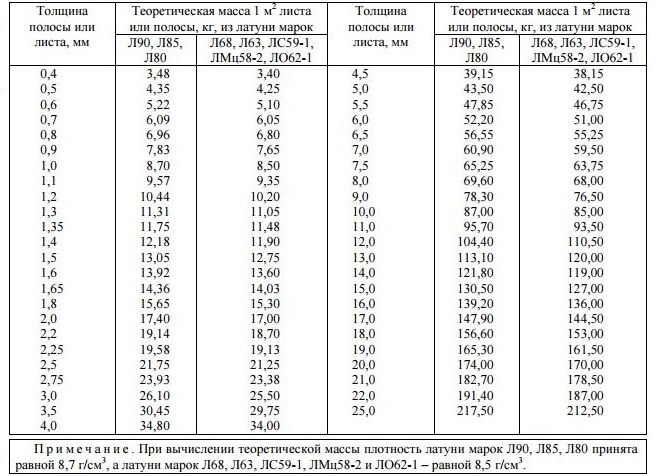

The theoretical weight of one square meter of rolled brass is also discussed in the 2007 standard, which, depending on the brand of alloy can be in the range of 3.4-217.5 kg This weight is calculated by the density of brass, from which the letter is made.

Theoretical mass per square meter of brass tape used, smug, sheets and foil

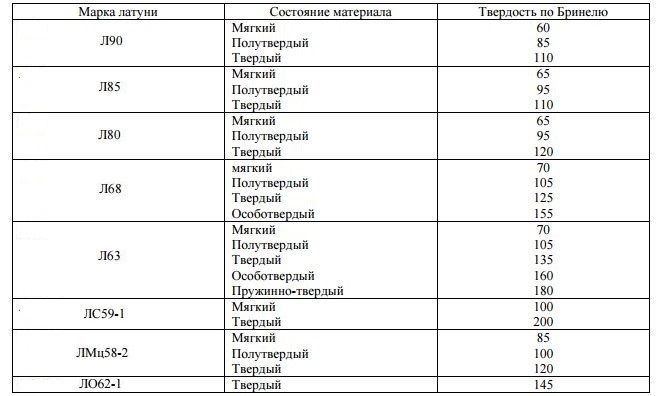

The provisions of the normative document discuss not only the geometric parameters of brass sheets and their theoretical weight, but also the hardness of the product, which may vary depending, in which version it is presented (soft, semi-solid, solid and especially solid).

Brinell hardness of brass alloys

Quality requirements

The above guests also list the requirements for the quality characteristics of rolled sheet metal. This should include:

- the presence of color variability on the surface of the sheet, darker, defects of various nature, serious contamination and other defects;

- the amount of allowable deflection of the sheets;

- the quality of trimming the edges of the sheets;

- the value of the elongation of the product;

- the magnitude of the temporary resistance to rupture.

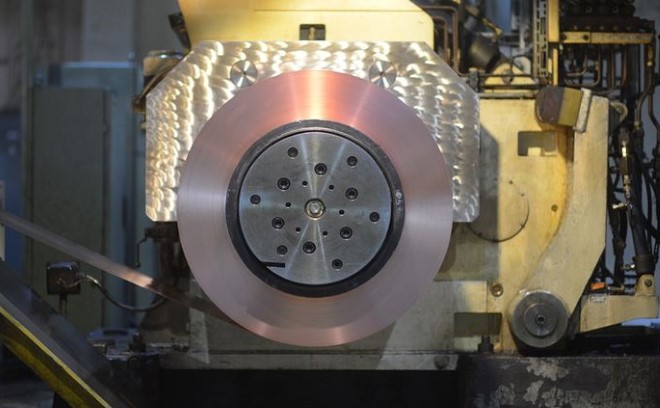

Checking the quality of cutting a wide brass cloth into strips

The normative document provides, that brass sheet metal, whose thickness does not exceed one centimeter, must be bent, which are performed along the rolling line. At the same time products, which have been subjected to such a test, further not tested for tension.

Marking rules, packing and transportation

Each batch of rolled sheet metal, regardless of its total weight and the number of products in it, should be released to the warehouse or to the consumer with a special label, which indicates the following information:

- batch number, the number of products in it and their total weight;

- trademark and name of the manufacturer;

- mark of product inspection by the quality department:

- brand of brass, from which the hire is made.

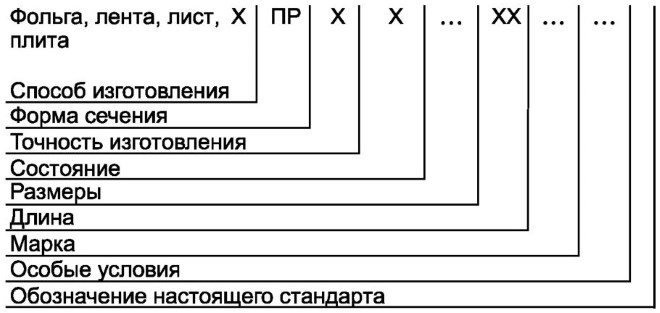

The scheme of marking brass sheets, tapes, foils and tapes

Brass sheets before their release to the warehouse or consumer are placed in bundles of a certain weight. Thus hire in thickness to 1,5 mm is placed in special boxes, which must protect it from mechanical damage. Bundles of brass sheets thicker 1,5 mm may be stored and transported without additional protective packaging. GOST determines how the size of the packs, formed of rolled brass, and their weight, which cannot exceed 1250 kg

Brass sheets with perforation

Modern industry also produces perforated sheets of brass alloys, which are used mainly for decorative purposes.

Perforated brass sheet is often used to hide heaters on the walls, and in the floor

Such letters, on the surface of which perforation of various configuration can be performed, actively used for manufacturing:

- furniture elements, trade and exhibition equipment;

- interior items;

- details of design of facades of buildings;

- small architectural forms and other elements for the formation of landscape design.