Cutters for metal lathes - classification, see, appointment

Specialists, who often use cutters for the lathe when performing work on metal, as well as those, who is engaged in the sale of these products or the supply of machine-building enterprises, well aware of that, what types of these tools are. The same, who often encounters in his practice with lathe cutters, it is quite difficult to understand their types, presented in the modern market in a great variety.

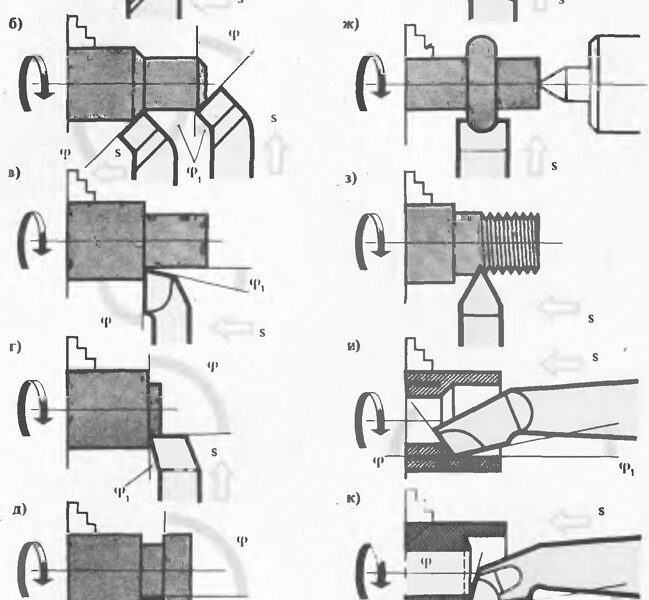

Types of turning cutters for metal processing

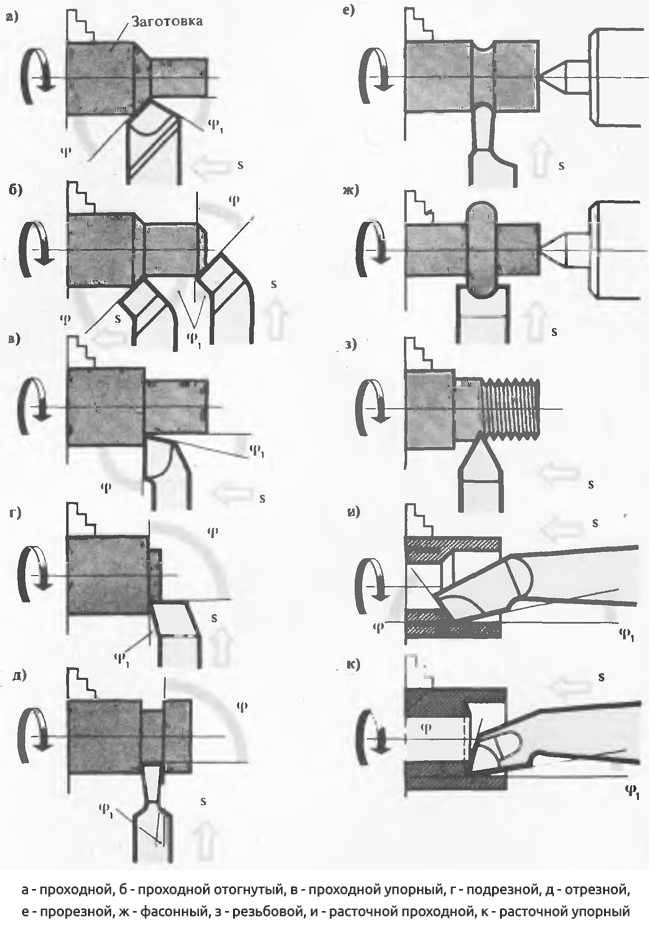

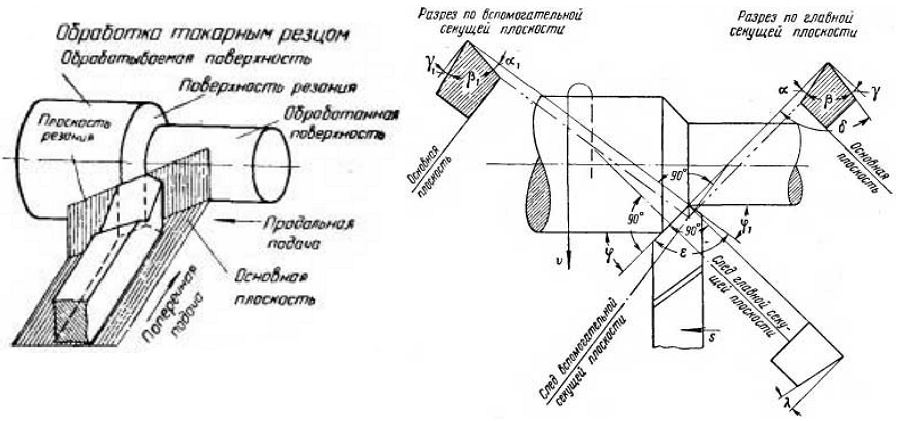

Design of a turning cutter

In the design of any cutter, used for turning, there are two main elements:

- holder, by means of which the tool is fixed on the machine;

- working head, by means of which metal processing is carried out.

The working head of the tool is formed by several planes, as well as cutting edges, the angle of sharpening which depends on the characteristics of the material of the workpiece and the type of processing. The holder of the cutter can be made in two versions of its cross section: square and rectangle.

Cutter design

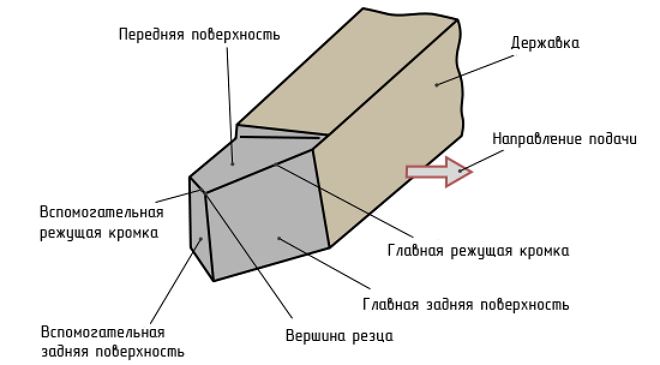

By its design, cutters for turning are divided into the following types:

- direct - tools, in which the holder together with their working head are located on the same axis, or two, but parallel to each other;

- the cutters are curved - if you look at such a tool from the side, it is clearly visible, that its handle is curved;

- bent - the bending of the working head of such tools in relation to the axis of the holder is noticeable, if you look at them from above;

- extended - such cutters have a smaller working head width, than the width of the handle. The axis of the working head of such a cutter may coincide with the axis of the holder or be offset relative to it.

Varieties of cutters by design

Classification of cutters for turning

Classification of turning cutters is regulated by the requirements of the relevant GOST. In accordance with the provisions of this document, cutters fall into one of the following categories:

- holistic tool, made entirely of alloy steel. There are also cutters, which are made of tool steel, but they are used very rarely;

- cutters, on the working part of which the plate is watered, made of hard alloy. Tools of this type are the most common;

- cutters with removable carbide inserts, which are attached to their working head with special screws or clamps. Cutters of this type are used much less often in comparison with tools of other categories.

Basic concepts, concerning the work of the lathe cutter, and its main corners

(press, to increase)

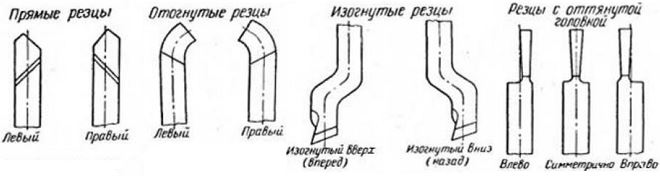

There are cutters and direction, in which the feed moves. So, happen:

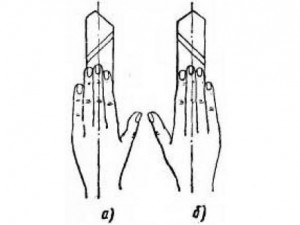

- turning tools of the left type - in the process of processing they are fed from left to right. If you put your left hand on top of such a cutter, then its cutting edge will be located on the side of the bent thumb;

- right cutters - type of tool, which is the most common, which is served from right to left. To identify such a cutter, it is necessary to put the right hand on it - its cutting edge will be located, in accordance, from the side of the bent thumb.

The difference between left and right incisors

Depending on that, what work is performed on turning equipment, cutters are divided into the following types:

- for finishing work on metal;

- for rough work, which are also called peelers;

- for semi-finished works;

- to perform fine technological operations.

Types of turning cutters for metal

In the article we will consider the whole range of turning cutters for metal and determine the purpose and features of each of them. An important clarification: whatever type the cutters belong to, certain brands of hard alloys are used as the material of their cutting plates: VK8, Т5К10, Т15К6, much less often T30K4, etc..

Passable straight cutters

Use a tool with a direct working part to solve the same problems, as bent cutters, but it is less convenient for chamfering. Basically such a tool for a metal lathe (by the way, did not become widespread) treat the outer surfaces of cylindrical workpieces.

Passable straight cutters

Holders of such cutters for the lathe are executed in two standard sizes:

- rectangular shape - 25 X 16 mm;

- square shape - 25x25 mm (products with such holders are used to perform special work).

Pass-through bent cutters

These are the types of incisors, the working part of which can be bent to the right or left, used for machining on a lathe end of the workpiece. They are also used to remove chamfers.

Pass-through bent cutters

Tool holders of this type can be made in different sizes (in mm):

- 16x10 (for training machines);

- 20x12 (this size is considered non-standard);

- 25x16 (the most common size);

- 32x20;

- 40x25 (products with a holder of this size are made mainly to order, they are almost impossible to find over the counter).

All requirements for metal cutters for this purpose are defined in GOST 18877-73.

Passable persistent bent cutters

Such tools for metal lathe can be made with straight or bent working part, but this design feature is not emphasized, and simply call them persistent checkpoints.

Passable persistent bent cutters

Pass-through thrust cutter, by means of which on the lathe processing of a surface of cylindrical preparations from metal is carried out, is the most popular type of cutting tool. Design features of such a cutter, which performs the processing of the workpiece along the axis of its rotation, allow even in one pass to remove from its surface a significant amount of excess metal.

Holders of products of this type can be made in different sizes (in mm):

- 16x10;

- 20x12;

- 25x16;

- 32x20;

- 40x25.

This tool for a metal lathe can also be made with a right or left bend of the working part.

Cutting bent cutters

Externally, such a cutting cutter is very similar to a checkpoint, but he has another shape of the cutting plate - triangular. With the help of such tools for a lathe on the metal workpieces are processed in the direction, perpendicular to the axis of their rotation. In addition to bent, there are also persistent types of such turning cutters, but their scope is very limited.

Cutting bent cutters

Cutters of this type can be made with the following sizes of holders (in mm):

- 16x10;

- 25x16;

- 32x20.

Cutting cutters

The cutting cutter is considered to be the most common type of tool for a metal lathe. In full accordance with its name, this cutter is used to cut workpieces at right angles. With its help also grooves of various depth on a surface of a detail from metal are cut. Identify, that in front of you is a cutting cutter for a lathe, quite simple. Its characteristic feature is a thin leg, on which the plate from a firm alloy is soldered.

Cutting cutters

Depending on design design allocate the right - and left-hand types of cutting cutters for the lathe on metal. It is very easy to distinguish them from each other. To do this, turn the cutter with the cutting plate down and look, on which side is his leg. If on the right, then he is right-handed, and if on the left, then, in accordance, nearside.

Such tools for a lathe on metal also differ in the sizes of the holder (in mm):

- 16x10 (for small training machines);

- 20x12;

- 20x16 (the most common size);

- 40x25 (such massive lathe cutters are hard to find over the counter, mostly they are made to order).

Thread cutters for external threads

Purpose of such cutters for the lathe on metal - cutting of a carving on an external surface of preparation. Metric thread is cut with these serial tools, but it is possible to change their sharpening and to cut with their help a carving of other kind.

Cutters for cutting external threads

Cutting plate, mounted on such lathes, has a spear-shaped shape, it is made of alloys, which were mentioned above.

Such cutters are made in the following sizes (in mm):

- 16x10;

- 25x16;

- 32x20 (used very rarely).

Cutters for cutting internal threads

With such cutters for the lathe it is possible to cut a carving only in an aperture of big diameter., due to their design features. Externally, they resemble boring cutters for blind holes, but do not confuse them, since they are fundamentally different from each other.

Cutters for cutting internal threads

Such cutters on metal in the following standard sizes are issued (in mm):

- 16х16х150;

- 20х20х200;

- 25х25х300.

The holder of these tools for a metal lathe has a square cross section, the dimensions of the sides of which can be determined by the first two digits in the designation. The third digit is the length of the handle. Depth depends on this parameter, on which it is possible to cut a carving in an internal aperture of preparation from metal.

Such cutters can be used only on those lathes, which are equipped with devices, called a guitar.

Boring cutters for processing blind holes

Boring cutters, the cutting plate of which has a triangular shape (as in different), perform processing of blind holes. The working part of tools of this type is made with a bend.

Boring cutters for blind holes

Holders of such cutters can have the following sizes (in mm):

- 16х16х170;

- 20х20х200;

- 25х25х300.

Maximum hole diameter, which can be machined with such a lathe cutter, depends on the size of its holder.

Boring cutters for processing through holes

Such cutters, the working part of which is made with a bend, through holes are processed, pre-drilled. Depth of hole, which can be machined with a tool of this type, depends on the length of its holder. A layer of metal, which is removed at the same time, approximately equal to the magnitude of the deflection of its working part.

Boring cutters for through holes

In the modern market boring cutters of the following standard sizes are presented, requirements for which are defined in GOST 18882-73 (in mm):

- 16х16х170;

- 20х20х200;

- 25х25х300.

Prefabricated cutters for lathes

Considering the main types of turning cutters, it is necessary to mention tools with a prefabricated design, which belong to the universal, as can be equipped with cutting plates of various function. Example, fixing on one holder cutting plates of different type, you can get cutters for machining metal workpieces at different angles.

Prefabricated cutters

Usually, such cutters are used on CNC machines or on special machines and are used for contour turning, boring of blind and through holes and other specialized works.

The classification of cutters for turning also includes slotted, shaped and some other types. It is possible to understand the principle of operation of such tools, after reading the table at the beginning of the article.