Selection of a drill on diameter to a carving: special tables and features of cutting

Any connection of a detachable type must have a thread. It is worth noting, that all hardware with an external thread, bolts, in particular, can be purchased anywhere: in a construction supermarket or market. And here with a carving of internal type everything is much more difficult. It should be cut with your own hands or using special machines.

Today we will tell, how to properly select drills of a diameter for a particular thread, you will also be able to read the table of these diameters.

The need for selection of drills for carving

To make your own interior thread, take your blank and drill a hole in it, which will correspond to the diameter of the tool, which is designed for slicing. And each of these holes must strictly correspond to the size of the tool. For this purpose it is necessary to select carefully under a carving diameter of a drill.

To date, there are drills with different diameters in size. Starting from the minimum size in 0,5 mm and ending with large conical drills about the size 0,05 mm. Depending on the type of work performed by drilling, you can make holes of different diameters for different needs.

Parameters of selection of a drill under a carving: table

If you need to drill a hole with a large diameter, then you will need to take a special machine, where drills are equipped with conical tails, but ordinary drills are equipped with cylindrical tails. On a large drill, the cone has a fifth size. So, the parameters of the cone directly depend on the diameter of the drill, the larger the diameter of the drill, the more you need a cone. example:

- diameter from 6 to 10 mm;

- the required cone size from 11 to 22 mm.

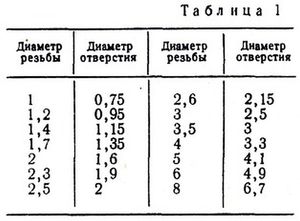

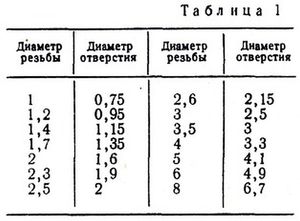

It is possible to pick up as much as possible precisely diameter of a drill under this or that carving, based on a special size selection table.

If there is a need to create an internal thread, the hole diameter should be selected according to the thread diameter and thread pitch parameters. These data in the tables are marked as M8? 1, where:

- M is a metric thread;

- the number is a threaded step;

- if specified simply M8 and without numbers, then you need to apply the standard large step. This parameter step is the most common and is fitted to most drill sizes.

Diameters require the selection of appropriate holes in size. The table includes a list of the most running sizes, which usually have to deal with in everyday life when performing certain works.

Thread classification

Externally, the thread is similar to a helical groove with a constant cross section. There are only two types:

- external;

- internal.

We have already mentioned these species. Threaded connections are widely used. They are needed for that, so that the part can rotate with the help of translational movements. It is difficult to imagine the normal operation of mechanisms or complex machines without threaded connections. They are also single-west or multi-west.

And in the direction of movement of their guides, they are divided into:

- left;

- right.

If we talk about the classification by size, then it happens to be such species:

- metric;

- inches;

- trumpet.

Metric thread has its own special triangular profile, the angle of which is 60 degrees. All thread parameters are considered in millimeters. If the thread pitch is large, then, as already mentioned, we have a number and a letter. The number indicates the size of the outer diameter of the thread, according to which it is possible to select that or a drill. Technical drawings must include a description of the thread or its analogues. If the metric thread needs to be presented with a small non-standard step, then you need to add a number, which indicates the step.

Another value of the angle of the profile is specific to the threaded connection of the inch type. This angle can be equal to 55 degrees, and the size of the hole is calculated in inches, the step varies with the number of threads.

And the pipe thread type differs from others in its initial diameter, which depends directly on the size of the pipe hole. Cutting is carried out in this case only external.

Features of thread cutting

Various equipment is used for threading, example:

- drilling machine;

- lathe park;

- various cutting devices.

This cutting can be performed as a mechanical method, so manually. Example, special threaded taps can be used for internal use, and for the outer - dice. Taps, as well as drills, are selected depending on the diameter of the hole. They are divided into the following categories:

- inches;

- metric;

- trumpet.

Basically, sets of hand taps consist of three devices, two of which are required for preliminary work, and the latter is a refining tool, by means of which the final form of a carving and adjustment under these or those sizes is carried out. Taps have numbers. If not complete with die holder, and two devices, the former are preliminary, and a friend is clean. Taps on the basis of high-alloy steel are made.

The external thread is obtained by using a die. These tools can be round or prismatic. For round dice use a collar.

Methods of obtaining internal threads

To make a hole in place, where you will need to perform slicing, you must first select the drill bit of the desired size.

To use the tap, its hole must be treated with a countersink, until the required degree of purity is obtained. When cutting the metal is gradually extruded.

The size of the drill should be slightly larger, than the internal thread diameter of this tool.

When cutting, the hardness of the metal does not greatly affect the diameter of the hole. But if a low-thread material is used, then the diameter of the hole can change significantly. So, if the size of the hole and the inner diameter of the drill exactly match each other, then when cutting the material is extruded, and its excess acts on the teeth of the tap. When heated, the shavings stick, as a result, the tap may break, and the thread will have torn threads.

When working with drills and threaded connections, you need to choose the parameters very carefully, that work as a result was executed qualitatively. Special tables with the indication of parameters under this or that carving and other valuable councils will help you with it..