Food grade stainless steel: steel grade, application, advantages

Food grade stainless steel, as abbreviated as stainless steel, which is used for the manufacture of products, which in the course of the operation come into contact with foodstuff and liquids, is a material with a special chemical composition. Properties of this metal, represented by different brands, determine a fairly wide scope of its application.

Stainless steel sheet 08X18H10(AISI 304) polished in film

Areas of application

To materials of production of various products, container, containers, pipelines and equipment, used in the food industry, there are particularly high demands. This is due to the fact, that such materials in the course of operation not only constantly contact with liquid and damp environments, but also exposed to high temperatures, as well as chemically aggressive substances.

Terms, in which are stored, food is transported and processed, ordinary stainless steel is not always able to withstand, though, characterized by high corrosion resistance. That is why experts have developed special stainless steels, belonging to the category of food.

Food manufacturers use stainless steel pipes, which are connected by appropriate fittings, which meets the requirements of the DIN standard 11850

Food grade stainless steel has a number of advantages, among which are the following:

- compliance with strict hygienic and toxicological requirements;

- aesthetically pleasing appearance;

- ease of maintenance;

- ecological safety;

- strength and durability;

- exceptional resistance to aggressive environments of various types;

- compliance with the requirements for the dissolution of heavy metals in the environment.

Not just a specialist, but any housewife knows, that the most convenient in care and beautiful are those pans and cutlery, which are made of stainless steel. in addition, from sheets of this metal make a deck for ovens, cooker cabinets, refrigerators and other household appliances. Recently, the scope of food grade stainless steel is constantly expanding.

Stainless steel is abundant in any kitchen: from cutlery to finishing facades of furniture

Stainless steel is an almost indispensable material, used for the production of various equipment and equipment of enterprises, dealing with production, processing and storage of food and liquids. In particular, containers of various volumes are made of this metal, pipes, trays, elements of technical devices, on which grind of foodstuff is carried out, mixing them, sorting and heat treatment.

Differences from ordinary stainless steel

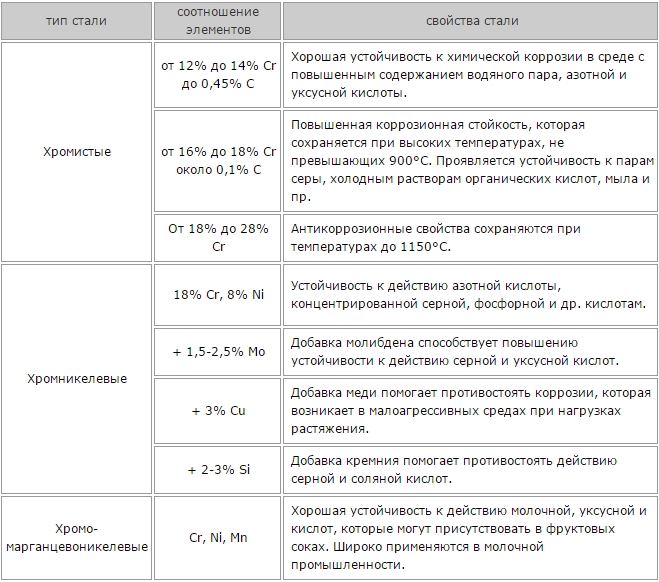

Stainless steel includes alloys, in the chemical composition of which contains a significant amount (to 27%) chromium. This element promotes the formation of an oxide film, which provides stainless steel with high corrosion resistance.

Varieties of stainless steels in terms of chromium content

To give stainless steel the required performance characteristics, to its composition, except chromium, introduce other chemical elements - nickel, molybdenum, titanium, etc. Yes, if stainless steel products, which contains 13-17% chromium, can be successfully operated only in slightly aggressive environments, then steel alloys with high content of this element (over 17%), as well as with nickel and molybdenum are already able to withstand the effects of salt solutions and even more aggressive environments.

Because there is no separate regulatory document for stainless steel food (Dstu), it is difficult to distinguish it from technical steel.

Theoretically, any brand of stainless steel can be used to make products, in contact with food or liquids. Corrosion resistance of such products, of which brands of stainless steel they were not made, depends not only on the chemical composition of the material, but also from operating conditions.

As production, and the process of storing and transporting food is subject to conditions, at which materials, in contact with such products, are constantly exposed to aggressive environments. Depending on the type and duration of exposure of the latter to the category of food include different brands of stainless steel. So, if capacity, the pipeline or pieces of equipment are in contact with food for a very short time, then for their manufacture you can use technical stainless steel. The issue of choosing steel for the manufacture of products for various purposes is solved quite differently, who will be in constant contact with food and liquids. Other grades of stainless steel should be used for such purposes. Obviously, that the category of food may include different brands of stainless steel alloys.

The most popular brands

Choosing a brand of stainless steel to make a particular product, experts first of all estimate, how long its surface will be in contact with food or liquids. So, for production used in the food industry products, which in the course of the operation will be constantly in contact with firm products or liquids, it is necessary to choose grades of steel alloys with the maximum resistance to corrosion. At the same time items, which come into contact with food for a short time (example, cutlery), can be made of stainless steel, less resistant to aggressive environments.

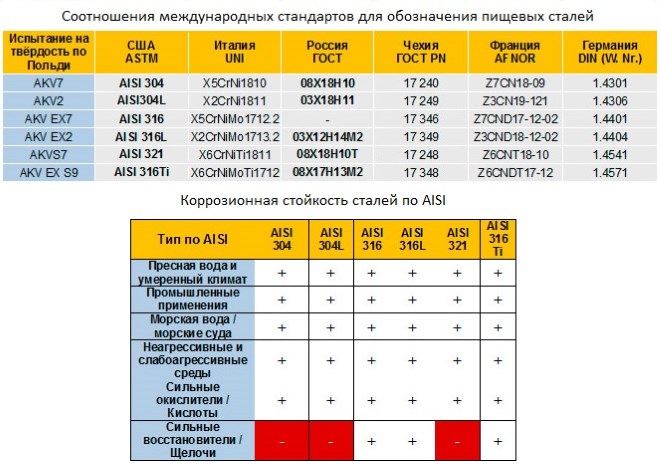

International standards for food steels

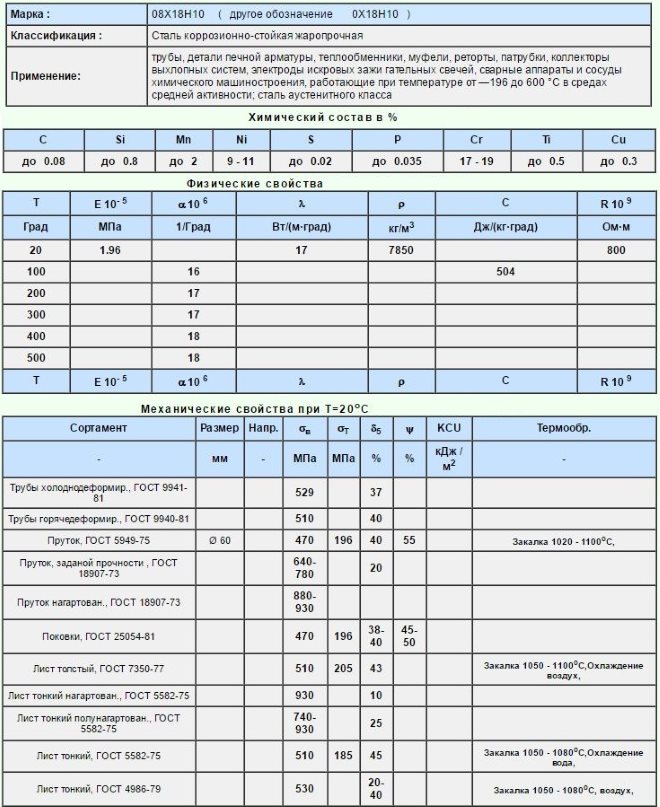

One of the most common stainless steel alloys, used in the modern food industry, there is steel 08Х18Н10 (on coding of AISI-304). This material is of low cost and can be successfully used for the manufacture of products, which in the course of the operation will not come into contact with solutions, containing caustic soda and sulfamic acids. High popularity of steel alloy of this brand, actively used in the food industry, provide the following characteristics, as:

- high strength, demonstrated at low heating temperature;

- the possibility of performing such a technological operation, as electric polishing;

- good weldability;

- high resistance to this phenomenon, as intergranular corrosion.

Technical properties of steel 08Х18Н10

Another popular brand of stainless steel, which is actively used, in particular, for the production of cutlery and kitchen utensils, there is steel 08Х13 (in the international classification - AISI 409). Products from this steel, has a high degree of adaptation to operating conditions, surrounding us in our kitchens.

For production as household, and industrial sinks, as well as utensils and special containers for heat and hygienic treatment of food products used stainless steel grades 20X13-40X13 (AISI 420). Along with high indicators of wear resistance and plasticity, steels of these grades perfectly resist even high-temperature corrosion.

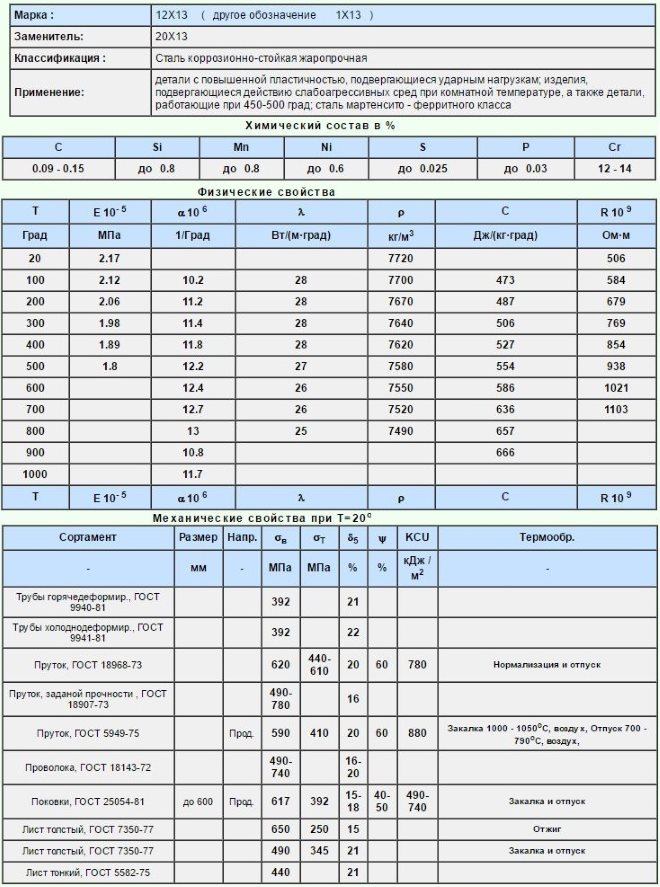

Food industry, for maintenance of which materials with special properties and especially high corrosion resistance are necessary, there is winemaking, alcohol production, as well as the sphere, associated with the processing of waste from such industries. Stainless steel brand, products from which perfectly show themselves in similar conditions, is 12X13 (AISI 410).

Technical parameters of steel 12X13

From such steel, which is characterized by exceptional corrosion resistance, high heat resistance under the influence of weakly aggressive environments, and increased toughness, produce various fittings and communication elements of food production, tanks and other containers of other types, where liquid aggressive environments remain for a long time.

For the manufacture of utensils and production tanks, in which food and liquids must be subjected to heat treatment, use stainless steel alloy grade 08X17 (AISI 430). The distinctive features of this alloy include:

- high corrosion resistance when interacting with media, containing sulfur in its chemical composition;

- optimal combination of high strength and ductility;

- high thermal conductivity;

- decent mechanical characteristics.

Various containers for storage and processing of food liquids are made of stainless steel alloy 08Х17

Among the universal stainless steel alloys, from which various sanitary devices are made, washing machines, refrigerators and other products, relating to steel of the 08X17T brand (AISI 439). Due to its characteristics, stainless steel of this brand can be successfully used for the production of products for various purposes, operated in conditions of high humidity and constant exposure to aggressive environments.

All stainless steel alloys, mentioned above, are actively used for production of products, designed for:

- food preservation, performed at home;

- food storage, including dairy;

- heat treatment of food, preparation of first and second courses.

Ware, made of food grade stainless steel, have long taken a worthy place in our kitchens, due to the truly unique characteristics of this material.