Cold stamping of metal and making stamps: technology, equipment

Cold stamping (HSH) is considered the most advanced method of processing metals by pressure. Its qualified application allows to receive products of various forms and the sizes. What is important, ware, made by this technology, differ in the accuracy of their geometric parameters and high quality of the formed surface, therefore do not require further refinement. The process of performing cold stamping can be easily automated, that gives the chance to make production with its help with high productivity.

These parts were made by cold stamping

Subtleties of technology

Stamping or stamping, as such a technological operation is often called, Is a process, in which the workpiece of metal under the influence of pressure is subjected to plastic deformation. As a result of such influence, for the provision of which special equipment is used, from the workpiece is formed a finished product of the required size and shape. Deformation of the metal workpiece can be performed with its preheating, then this process is called hot stamping. If no previous thermal effect on the workpiece is detected, then cold stamping of metal is performed.

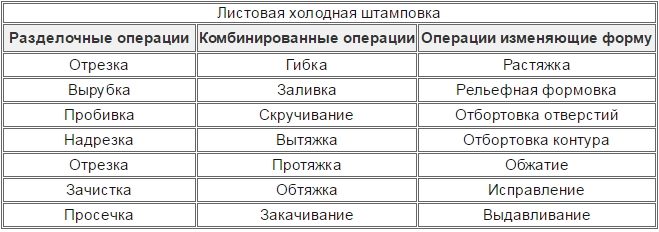

Classification of basic stamping operations

When performing cold stamping of metal, special technological equipment is used. The metal, from which the workpiece is made, is subject to additional strengthening. Meanwhile, when performing cold stamping of the metal deteriorates its ductility. Increasing the strength of the workpiece when performing cold stamping leads to an increase in the fragility of the metal, which is a very negative factor. To avoid this, between technological operations, which consists of stamping parts in the cold state, perform heat treatment of the workpiece - recrystallization annealing. In finished products, which in the process of production were subjected to such heat treatment, the parameters of strength and plasticity are optimally combined.

Types of cold stamping

To change the initial geometric parameters of the metal sheet in several directions, cold volume stamping is used. In order not to increase the resistance of the metal and, in accordance, do not reduce its fluidity, such a technological operation is performed at temperature, which does not exceed forging.

Cutting washers is the simplest example of cold stamping

Using this technology, which requires the use of special equipment, produce high-precision products, without such defects, like hot cracks, scratches, burrs and risks, plots, subjected to shrinkage of metal. However, because of that, that stamping press, used to perform volumetric HS, forced to overcome the insane resistance of unheated metal, to get with its help details of a difficult configuration is problematic. In such cases, it is better not to use cold, and hot stamping.

Another type of metal pressure treatment, when performing which blanks are not subjected to preheating, there is a cold sheet stamping. When performing processing by this method as blanks can be a sheet, tape or strip, made of metal. The wall thickness of the workpiece when using this technology does not change, and you can get three-dimensional products only from plastic metals.

Stages of making stamps

The design of dies for cold stamping plays an important role in ensuring the required quality of the finished product, due to which the formation of parts with the required geometric parameters. Work drawings of such work tools should be performed, which are established on stamping presses, can as two-, and in three-dimensional format. Relevant knowledge and skills are required to solve this problem.

Development of drawings and subsequent production of the stamp, used for cold stamping, performed in several stages:

- sketching the future stamp;

- study of the scheme, on which cutting of material will be carried out, verification of such a scheme using a special computer program;

- sketch editing, if necessary;

- final check of the sizes of the developed stamp;

- marking the position and exact dimensions of the holes, which will be made on the working surface of the stamp.

When designing stamps, you often have to choose between the quality of the future part and the cost-effectiveness of production

Developing stamps for cold stamping, it is necessary to break the drawings of the finished product into separate parts and carefully study them. After such a procedure is performed, carry out the production of stamps. It is necessary to pay special attention to the requirements, which are presented to the parameters of the finished product. A route map is developed for each stage of the cold stamping process, in which are taken into account as the time of execution of individual operations, and characteristics of forgings at separate stages of processing.

Most stamps are made of carbon or alloy steel, but aluminum and copper alloys are sometimes used

In this matter, as a performance of cold stamping of a metal workpiece, many parameters have values, to which, in particular, include the sequence of technological operations, distribution of material in the cavity of the working tool, used equipment and processing modes.

There are also serious requirements for the process of making cold stamping dies, because the quality of the molded product depends on the accuracy of this tool.

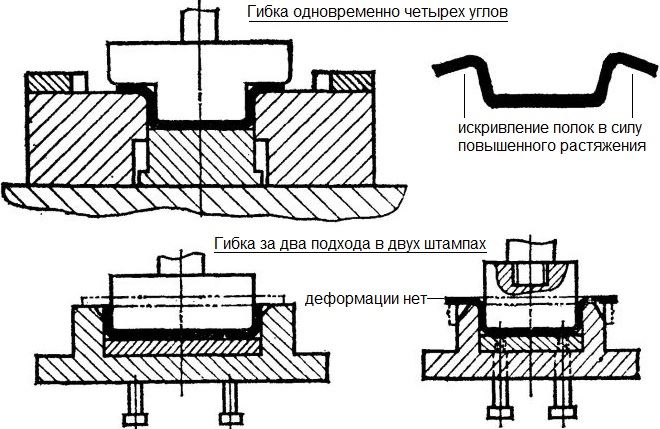

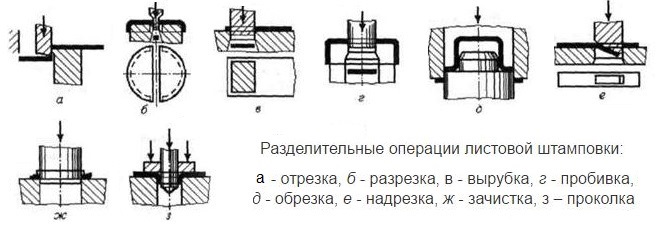

Stamping of details, in which sheet metal is used as a blank, may include a list of mechanical operations. Such operations, in particular, there is cutting, felling, extrusion, flexible, cold landing, formation, crimping and extraction. At the same time cutting, felling and a number of other technological operations belong to the separation operations, and cold landing, molding, bending, etc.. - to shape-changing.

Types of separation operations of sheet metal stamping

Types of shape-changing sheet metal stamping operations

After stamping, the product can be subjected to a number of ancillary operations, which include annealing and digestion. By means of such operations the finished product is given the necessary mechanical characteristics. To increase the wear resistance of products, obtained by cold stamping, various protective coatings are applied to their surface.

If the sheet metal blank needs to be subjected to volumetric stamping, then such an operation can be performed according to two technological schemes.

The first of them consists of three operations:

- pre-heat treatment of the workpiece (it is necessary for that, to reduce the strength of the metal);

- preparation of the workpiece surface for stamping;

- directly to the stamping itself.

When performing cold stamping with the second technological scheme to the above three stages is added another - preliminary preparation of dimensional blanks, from which the finished products will be formed.