Chrome plating at home: technology, video

Elements, covered with a layer of chrome, usually, used to improve the design of cars and motorcycles. The cost of such details, manufactured in production conditions, quite high, and meanwhile it is quite possible chrome plating at home. Applying chrome on the surface of various products with your own hands, you can save a lot of money.

Adherence to technology will allow to receive chromeplated surfaces of good quality and in house conditions

Many craftsmen are interested in chrome plating various parts with their own hands at home, who are not indifferent to the appearance of their vehicle. There are many nuances in the technology of chrome plating at home. in addition, it requires strict adherence to the sequence of all stages.

Preparation for the procedure

To perform chrome plating at home, some training is needed. First of all, you should choose the right room (preferably non-residential). in addition, must be performed before chrome plating:

- provide ventilation of the room, in which the technological operation will be performed (it is desirable, that such ventilation was not natural, and forced);

- find the means, ensuring personal safety (respirator, goggles, tight rubber gloves and apron);

- resolve the issue, how the waste of the technological process will be disposed of.

Homemade chrome bath can be made of thick vinyl

Chrome plating design

You can make a device for chrome plating at home, consisting of the following elements:

- container, in which the capacity for performance of chromium plating will be established;

- the capacity itself, as which you can use a glass jar with a volume 3 liters;

- wooden box with insulated walls, which contributes to the quality of the electrolysis process (as insulating elements of the walls of such a box, which must have a thermos effect, you can use fiberglass, sand, mineral wool or glass wool);

- heating element, which can act as a conventional heating element of appropriate power;

- device, with which you can measure the temperature (it is best to use a contact thermometer, which allows to automate the technological process);

- sealing cover, which is better to make of a wooden board or moisture resistant plywood;

- wires, by means of which the processed product is connected to a negative contact of an electric current source, and the anode, also immersed in electrolytic solution, - to the plus (wire, connected to the workpiece, it is best to equip a clamp type "crocodile": it will be much more convenient to connect it in this case).

Installation scheme for chrome plating

In the set of the set for chromeplating it is necessary to include also a special arm for suspension of the processed detail in electrolyte. It is necessary to use such arm for that, so that the surface of the product is covered with a layer of chrome evenly on all sides.

Power supply requirements

Coating the surface of the products with a layer of chrome, including chrome plating of details in house conditions, involves the use of a DC source. The electrical circuit of a homemade chrome-plating device must meet the following requirements.

- Power source, which is equipped with a set for chrome plating, must be able to adjust the output voltage. In the simplest embodiment, a conventional rheostat can be used as such a control device.

- Intersection of wires, by which the anode and cathode are connected to a current source, is selected by the maximum current. So, equipment, used for chrome plating of small products, must be equipped with wires, the cross section of which is not less 2,5 mm2.

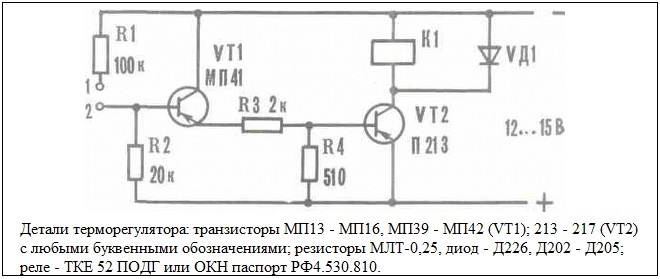

- If the household appliance for chrome plating involves the use of an unusual thermometer, and the thermostat, then for the correct use of such a measuring device it is necessary to assemble an appropriate electronic circuit.

Thermostat circuit

The composition of the electrolyte and the rules of its preparation

In that case, if you decide to apply a layer of chrome on the surface of the product with your own hands, it is important not only to assemble the appropriate equipment, but also to properly prepare the electrolytic solution. The composition of such a solution for chromium plating of metal includes the following components:

- chromic anhydride (CrO3) – 250 g / l;

- sulfuric acid (H2SO4) – 2,5 g / l.

These components are miscible with water.

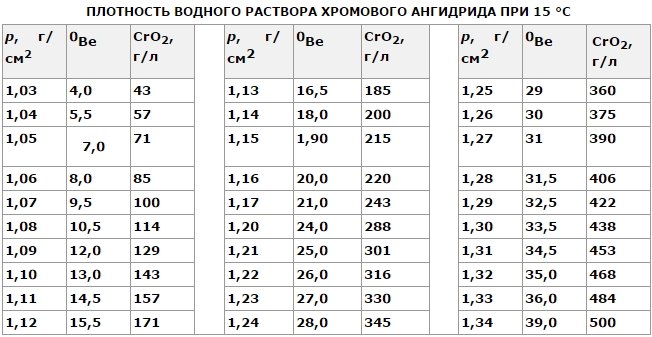

After mixing with a hydrometer check the density of the solution, which can be judged on the content of chromic anhydride

There are certain rules for preparing an electrolytic solution, which are as follows.

- Capacity, in which the electrolyte is prepared, half filled with water. In that case, if not distilled, and ordinary water, it should be boiled and allowed to stand. Water temperature, to which other components are added, should be about 60 °.

- After the water is prepared and heated to the required temperature, it is filled with chromic anhydride and the resulting mixture is stirred until completely dissolved.

- If the volume of the solution has decreased, it is necessary to add water.

- Sulfuric acid is poured into the resulting solution. This should be borne in mind, the above values of H2SO4 in solution are relevant for the acid, having a specific density 1,84.

- Once the electrolyte is ready, it needs to be "refined". Through him for 3,5 hours of electric current, the strength of which is calculated by the following formula: 6,5 And for every liter of solution. Knowing the technical characteristics of the current source used, you can easily determine the required amount of electrolyte. If all the steps to "process" the electrolytic solution are performed correctly, then its color will change to dark brown.

- Electrolytic solution, by means of which chrome plating of details by the hands will be carried out, it is necessary to allow to settle in a cold room during the day.

How to prepare the workpiece

From that, how correctly and carefully prepared chrome-plated surface, depend on the quality and durability of the coating applied to it. While the finished electrolytic solution is defended, you can prepare the product, which is to perform a certain list of actions.

Cleaning

In the process of cleaning not only traces of dirt are removed from the workpiece before chrome plating, but also the remnants of old paint, rust, as well as any other foreign layers. Tools and accessories, used for cleaning, are selected depending on, how heavily contaminated the surface is. To perform such a procedure, in particular, can be used as ordinary sandpaper, and a grinder.

Degreasing

Chrome plating technology at work or at home requires mandatory degreasing of the treated surface. The characteristics of the applied chrome coating also depend on the quality of this procedure.

For degreasing, usually, a special solution is prepared, which allows you to perform this procedure as efficiently as possible. The most popular of these aqueous solutions includes the following components:

- sodium hydroxide - 150 g / l;

- silicate glue - 5 g / l;

- soda ash - 50 g / l.

The solution is heated to a temperature of 80-90 ° and keep the product in it for 20 minutes. If the surface of the workpiece is highly complex or heavily soiled, then the exposure time in the degreasing solution can be increased to 1 years.

How is chrome plating

After, how all the preparatory work is done, a natural question arises: how to chrome a detail correctly? First of all, it is necessary to heat the electrolytic solution to the required temperature (53±2°) and maintain it throughout the processing. After that, the product is placed in the electrolyte, in which the anode should already be. After a while, during which the temperature of the product is equal to the temperature of the electrolytic solution, an electric voltage is applied to the anode and the product.

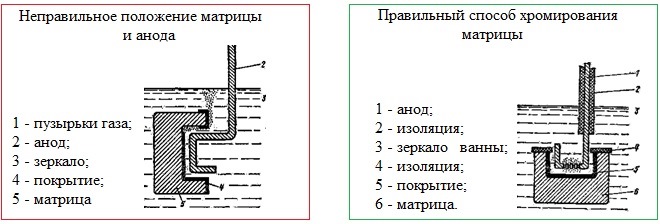

To evenly cover the surface with chrome, it is necessary to correctly place the workpiece and the inner anode

After chrome plating, the product is removed from the electrolyte and placed in a heating oven, where during 2,5 hours are subjected to heat treatment. This is necessary for that, not only to improve the adhesion of the chromium layer to the surface of the base metal, but also increase the hardness of the coating.

To perform decorative chrome plating of the highest quality, it is important to study the theoretical material and learn the features of such a process (example, video), as well as responsibly approach all stages of preparation of the part and the electrolytic solution.

It is best to chrome the prototype before processing the product, to work out all the nuances of the technological process.

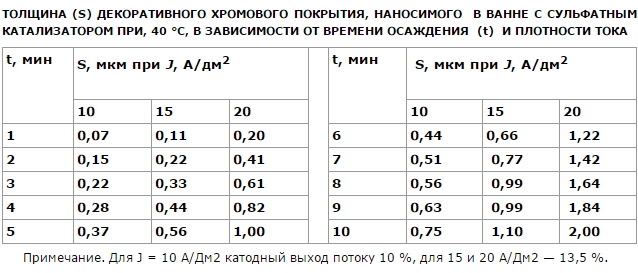

The duration of chrome plating and the current density affect the thickness of the finished coating

Defects of a chrome covering and the reasons of their occurrence

Performing chrome plating with your own hands, many home builders are faced with the most common defects of the coating, which can occur for various reasons.

1. The coating has a shine, but it is uneven.

- Amperage, supplied to the product and the anode, too big.

- The temperature of the electrolytic solution is not brought to the required value.

2. Gloss on the applied coating is completely absent.

- There is too much or not enough chromium anhydride in the electrolytic solution.

- Operating current rating exceeded.

- The amount of sulfuric acid in the solution is insufficient.

3. Brown spots appeared on the chrome surface.

- The amount of chromium anhydride in the electrolytic solution is exceeded.

- Sulfuric acid is lacking in the chromium plating solution.

4. Small sinks are visible on the applied coating.

- The treated surface was insufficiently prepared.

- When treated in solution, hydrogen is removed from the surface. To solve such a problem, it is necessary to change the layout of the product in solution and the method of its subsequent drying.

5. Chrome coating is characterized by unevenness.

- The operating current is exceeded.

6. The coating turned out to be too soft.

- The operating current is underestimated.

- The temperature of the electrolytic solution is above the required value.

7. The applied coating peels off.

- High-voltage, supplied to the anode and cathode, unstable.

- The surface of the processed product was not well degreased.

- The temperature of the electrolyte during processing decreased.

So, to apply a layer of chrome on the product with your hands, it is not enough to simply assemble your galvanic apparatus and study the theoretical basis, it is also important to consider many nuances, which directly affect the quality of the finished coating. That's why it's important to know more than just that, how to perform chrome plating, but also about that, how to do so, that the formed chrome covering differed in guaranteed quality.

Nuances of technology

The room for chrome plating with your own hands at home should not only be non-residential, but also spacious enough.

The following nuances should be taken into account when performing preparatory activities.

- Polishing products, performed before chrome plating, should be of the highest quality.

- All chemical reagents used in the chromium plating process must be measured in accurate quantities.

- Only chemically pure sulfuric acid should be used to prepare the electrolyte, but with the search and purchase of chromic anhydride issues will have to be resolved separately, as in free sale it is not found.

Chromic anhydride is a reagent in the form of red-violet crystals. Blurs in the air, hygroscopic, very strong oxidant

For chrome plating it is necessary to choose a source of a direct current, whose power will be enough for that, to handle products of different sizes. Naturally, the capacity for the electrolyte must be of sufficient volume.

To a layer of chrome, applied to the product with your own hands, was high quality, it is necessary to strictly follow the technological recommendations and closely monitor all operating parameters of the process.