How to cut a thread with a tap: thread cutting technology, size chart

The question is, how to cut a thread with a tap, occurs in those cases, when the previously made hole must be prepared to accommodate the bolt, screw, pins and threaded fasteners of any other type. The tap is the main tool in such situations, which allows you to quickly and accurately cut the internal thread with the required geometric parameters.

Manual cutting of internal threads is performed by metalwork taps complete with collar

Varieties and areas of application of taps

Internal threading can be done manually or with different types of machines (drilling, lathes, etc.). Working tools, who perform the main work of cutting internal threads, there are machine-manual or machine taps.

The taps are divided into different types depending on a number of parameters. The following principles of classification of taps are generally accepted.

- According to the method of rotation, there are machine-manual and machine taps, by means of which cutting of an internal carving is carried out. Machine-hand taps, equipped with a square shank, used complete with a special device with two handles (this is the so-called collar, tap holder). By means of such device the tap is put in rotation and cuts a carving. Tapping carving machine type is carried out on metal-cutting machines of various types, in the cartridge of which such a tool is fixed.

- Behind the way, which cut the internal thread, distinguish universal (checkpoints) and complete taps. The working part of the first is divided into several sections, each of which differs from the others by its geometric parameters. Work area, which first begins to interact with the treated surface, performs roughing, the second is intermediate, and the third, located closer to the shank, - clean. Several tools are required to cut the thread with complete taps. So, if the kit consists of three taps, then the first of them is designed to perform roughing, the second - for the intermediate, the third - for the finish. Usually, the set of taps for cutting of a carving of a certain diameter includes three tools, but in some cases, when the products are processed, made of particularly solid material, kits can be used, consisting of five instruments.

- By hole type, on the inner surface of which it is necessary to cut a thread, distinguish between taps for through and blind holes. The tool for processing through holes is characterized by an elongated conical tip (west), which smoothly passes into the working part. Taps of universal type most often have such design. The process of cutting the internal thread in the blind holes is carried out with taps, the conical tip of which is cut off and performs the function of the simplest cutter. This design of the tap allows you to cut with it a thread to the full depth of the blind hole. For threading of this type, usually, a set of taps is used, manually rotated, using the collar.

- On a design of a working part taps can be with direct, screw or shortened chip chucks. It should be borne in mind, that you can use taps with grooves of different types to cut threads in products made of relatively soft materials - carbon, low-alloy steel alloys, etc.. If the thread must be cut in detail, made of very hard or viscous materials (stainless, heat-resistant steels, etc.), then taps are used for these purposes, cutting elements which are arranged in a checkerboard pattern.

A good tap is made of quality tool steel, looks neat and has exactly drilled turns and grooves

Taps, usually, used for metric threading, but there are tools, by means of which cut a pipe and inch female thread. in addition, taps also differ in the shape of their work surface, which can be cylindrical or conical.

Preparation for internal thread cutting

In order that the process of cutting an internal carving by means of a tap did not cause special difficulties and came to the end with qualitative result, it is necessary to properly prepare for this technological operation. All methods of tapping with a tap are assumed, that a hole with a corresponding diameter has already been made in the workpiece. If the internal thread, which must be cut, has a standard size, then to determine the diameter of the preparatory hole can be used a special table with data according to GOST.

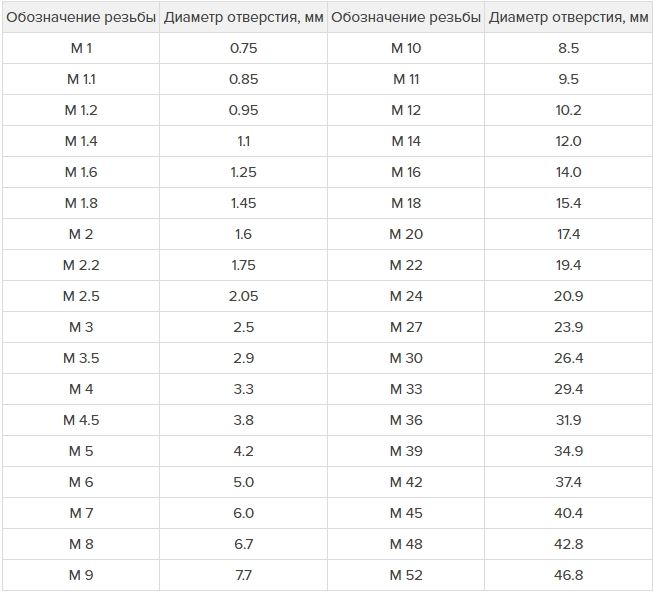

Table 1. Diameters of holes, drilled under a standard metric thread

In that case, if the thread, which must be cut, does not belong to the category of standard, calculate the diameter of the hole for its implementation can be a universal formula. First of all it is necessary to study marking of a tap, in which the type of thread must be specified, its diameter and pitch, measured in millimeters (for metric). Then, to determine the cross-sectional size of the hole, which must be drilled for threading, it is enough to subtract a step from its diameter. Example, if the tool with marking M6х0,75 will be used for cutting of a non-standard internal carving, then the diameter of the preparatory hole is calculated as follows: 6 — 0,75 = 5,25 mm.

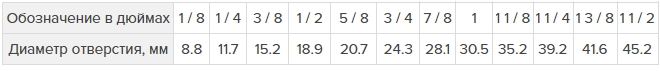

For standard threads, belonging to the category of inches, there is also a table, which allows you to choose the right drill, by means of which carry out preparatory works.

Table 2. Diameters of holes, drilled under an inch thread

The question of not only that is important for obtaining a quality result, than cut a carving, but also about that, which drill to make a preparatory hole. Choosing a drill, it is necessary to pay attention to parameters and quality of its sharpening, and also on that, that it rotates in the cartridge of the used equipment without beating.

The sharpening angle of the cutting part is selected depending on, which has the hardness of the material, which must be drilled. The higher the hardness of the material, the greater the angle of sharpening of the drill, but this value should not exceed 140 °.

When drilling blind holes, control the depth of drilling

How to cut a thread? To begin, you need to choose the tools and consumables:

- electric drill or drilling machine, able to operate at low speeds;

- drill, the diameter of which is calculated or selected according to reference tables;

- drill or countersink, with which the edge of the prepared hole will be chamfered;

- set of taps of the corresponding size;

- manual holder for taps (collar);

- metalwork vices (if the product, in which it is necessary to cut a carving, must be recorded);

- core;

- hammer;

- machine oil or other composition, which in the process of processing must be lubricated as a tap, and cut them a thread;

- rags.

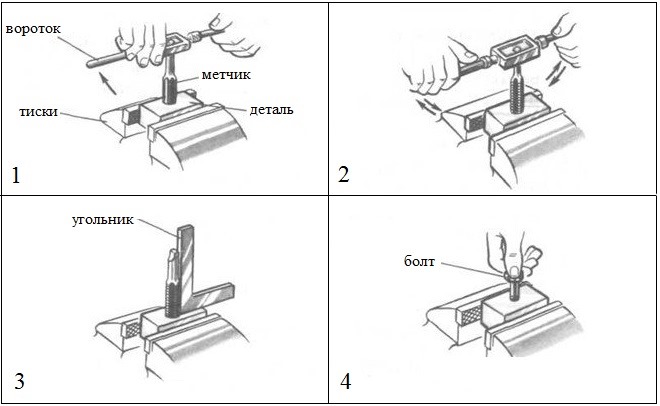

The scheme of threading with a tap

features of technology

When cutting the internal thread with a tap are guided by the following algorithm.

- In that place on the surface of the workpiece, where the threaded hole will be bored, it is necessary to form a recess for a more accurate approach of the drill, using a core and a regular hammer. The drill is fixed in the chuck of an electric drill or drill, on which low turns of rotation of the tool are exposed. Before drilling, the cutting part of the drill must be treated with a lubricating composition: lubricated tool is easier to enter the structure of the workpiece and creates less friction in the area of processing. You can lubricate the drill with a piece of ordinary lard or solid oil, and when processing viscous materials, machine oil is used for this purpose.

- If you need to cut a thread in small parts, they should be pre-recorded, using metalwork vices. Starting drilling, tool, fixed in the equipment cartridge, must be placed strictly perpendicular to the surface of the workpiece. The tap should be lubricated regularly and monitored, so that it does not skew and move strictly in a given direction.

- At the entrance to the hole, as mentioned above, the chamfer must be removed, the depth of which should be 0,5-1 mm (depending on the diameter of the hole). For this purpose, you can use a drill bit with a larger diameter or countersink, installing them in the chuck of the drilling equipment.

- The process of cutting the internal thread begins with the tap №1, which is first installed in the collar. Do not forget about the oil, which must be applied to the tap for threading. The position of the tap relative to the hole to be machined must be set at the very beginning, since then, when the tool is already inside the hole, it will not work. Cutting the thread with a tap, the following rule must be followed: 2 the rotation of the tap is done in the course of threading, 1 - against the move. When the tap is made one turn back, chips are dropped from its cutting part and the load on it is reduced. Dies are cut by a similar method.

- Having cut a carving with a tap №1, the tool встановлю2 is installed in the collar, and after it - №3. Processing them is performed according to the above method. When cutting the thread with taps and dies must be felt, when the tool starts to rotate with effort. As soon as such a moment comes, you should turn the collar in the opposite direction, to reset the chips from the cutting part of the tool.

The harder the material is processed, the more it is necessary to grease a tap in the course of cutting of a carving

Before performing internal threading with a tap or die-cutting on external surfaces, these procedures should be well studied and the rules of their conduct strictly followed. Only in this case you can count on it, that the result will satisfy you with its quality and accuracy.