How to harden metal at home: video, ways

If you know, how to harden metal properly, then even at home you can increase the hardness of products from it in two or three times. Reasons, on which there is a need for it, can be very different. Such a technological operation, in particular, required in that case, if the metal needs to be given hardness, enough for that, so that he could cut the glass.

Hardening of metal at home

Most often it is necessary to harden the cutting tool, moreover, heat treatment is performed not only in that case, if it is necessary to increase its hardness, but also then, when this characteristic needs to be reduced. When the hardness of the tool is too low, its cutting part will be engaged during operation, if it is high, then the metal will crumble under the influence of mechanical loads.

Few people know, that there is an easy way, allowing you to check, how well hardened the steel tool is, not only at work or at home, but also in the store, when buying. In order to perform such a check, you will need a regular file. They spend on the cutting part of the purchased tool. If it is hardened badly, then the file will seem to stick to its working part, otherwise, it is easy to move away from the instrument under study, with the hand, in which the file is located, will not feel any irregularities on the surface of the product.

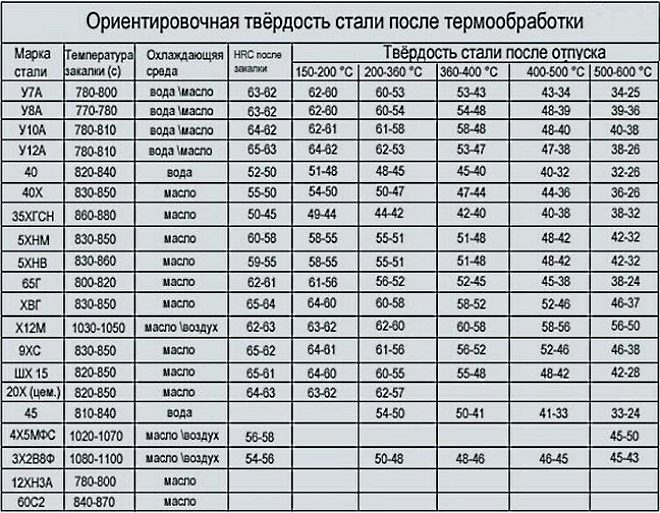

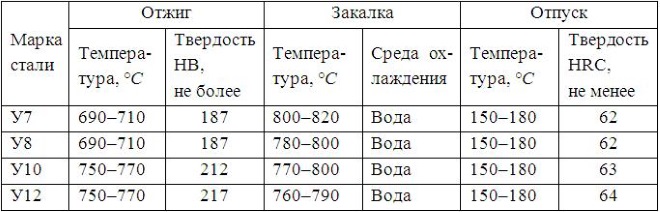

Dependence of steel hardness on the heat treatment mode

If it still happened, that you have the tool, the quality of hardening which does not suit you, it is not necessary to worry about it. This problem is solved quite easily: it is possible to harden metal even in house conditions, without using sophisticated equipment and special devices. However, you should know, non-hardenable low carbon steels. At the same time, the hardness of carbon and tool steel alloys is quite easy to increase even at home.

Technological nuances of hardening

Hardening, which is one of the types of heat treatment of metals, performed in two stages. First, the metal is heated to a high temperature, and then cooled. Various metals and even steels, belonging to different categories, which differ from each other in their structure, therefore, the modes of heat treatment do not match.

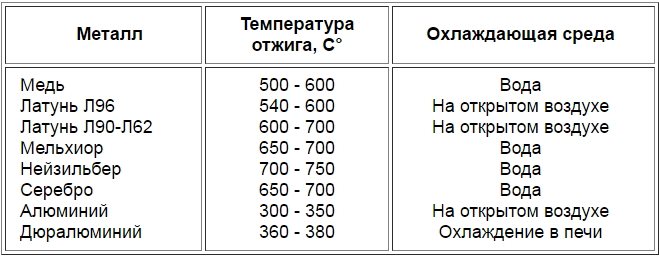

Heat treatment modes of some non-ferrous alloys

Heat treatment of metal (gart, vacation, etc.) may be needed for:

- its strengthening and increasing hardness;

- improving its plasticity, that is necessary at processing by a method of plastic deformation.

Many specialized companies harden steel, but the cost of these services is quite high and depends on the weight of the part, which must be subjected to heat treatment. That is why it is advisable to do it yourself, especially since it can be done even at home.

If you decide to harden the metal yourself, it is very important to perform this procedure correctly, as heating. This process should not be accompanied by the appearance of black or blue spots on the surface of the product. About that, that the heating is done correctly, indicates the bright red color of the metal. The video demonstrates this process well, which will help you get an idea of it, to what extent to heat the metal, subjected to heat treatment.

As a heat source for heating to the required temperature of the metal product, which need to be hardened, can be used:

- special oven, running on electricity;

- blowtorch;

- outdoor fireplace, which can be bred in the yard of your home or cottage.

Hardening of a knife on open coals

The choice of heat source depends on it, to what temperature the metal should be heated, subjected to heat treatment.

The choice of cooling method depends not only on the material, as well as from that, what results need to be achieved. If, example, it is necessary to harden not all product, but only its separate plot, then cooling is also carried out pointwise, for which a stream of cold water can be used.

Technological scheme, on which the metal is hardened, can predict instantaneous, gradual or multistage cooling.

Rapid cooling, for which a cooler of the same type is used, optimally suited for that, to harden steel, belonging to the category of carbon or alloy. One tank is required to perform such cooling, as which a bucket can be used, barrel or even a regular bath (it all depends on the dimensions of the workpiece).

Cool the knife blank in oil

In that case, if you need to harden steels of other categories or if in addition to hardening you need to take a vacation, a two-stage cooling scheme is used. In this scheme, the product heated to the desired temperature is first cooled with water, and then placed in mineral or synthetic oil, in which further cooling takes place. Under no circumstances should you use an oily cooling medium at once, as the oil may ignite.

In order to properly select the tempering modes of different grades of steel, should focus on special tables.

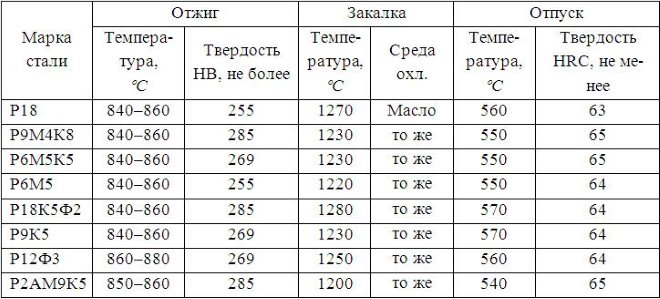

Modes of heat treatment of high-speed steels

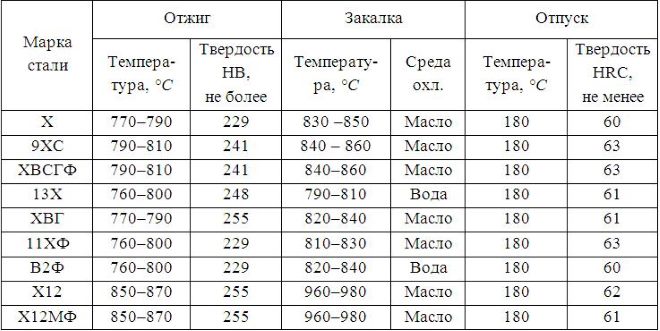

Modes of heat treatment of alloy tool steels

Modes of heat treatment of carbon tool steels

How to harden steel over an open fire

As mentioned above, it is possible to harden steel and in house conditions, using an open hearth to heat. Start such a process, naturally, traces of bonfires, in which a lot of hot coals should be formed. You will also need two containers. In one of them you need to pour mineral or synthetic oil, and in the other - ordinary cold water.

To remove the hot iron from the fire, you will need blacksmith tongs, which can be replaced by any other tool for similar purposes. After, how all the preparatory work is done, and a sufficient amount of hot coals was formed in the hearth, you can put objects on them, which need to be hardened.

The color of the coal formed can be judged by the temperature of their heating. So, coal is hotter, the surface of which has a bright white color. It is also important to watch the color of the fire flame, which indicates the temperature in its interior. Best of all, if the flame of the fire is painted crimson, not white. In the latter case, indicating that the flame temperature is too high, there is a risk not only of overheating, but even burn metal, which must be hardened.

The colors are incandescent

The color of the heated metal must also be closely monitored. In particular, cannot be allowed, so that black spots appear on the cutting edges of the workpiece. Blue metal indicates this, that it is very soft and very plastic. It cannot be brought to such a state.

After the product is calcined to the required extent, you can proceed to the next stage - cooling. In the first place, it is lowered into a container with oil, and do it often (with a frequency of 3 seconds) and as sharply as possible. Gradually the intervals between these dives increase. As soon as the hot steel loses its color brightness, you can start cooling it in water.

Colors of variability of steel

When water-cooled metal, on the surface of which there were drops of hot oil, caution should be exercised, since they can flare up. After each immersion, the water must be shaken, to keep it cool all the time. An educational video will help to get a clearer idea of the rules of such an operation.

There are some subtleties in cooling hardened drills. So, they must not be lowered into the tank with coolant plasma. If you act this way, then the bottom of the drill or any other metal object, having an elongated shape, sharply cooled first, which will lead to its compression. That is why it is necessary to immerse such products in the coolant from the wider end.

For heat treatment of special grades of steel and melting of non-ferrous metals the possibilities of the open hearth will not suffice, as it will not be able to heat the metal to temperature 700-9000. For such purposes it is necessary to use special furnaces, which can be muffled or electric. If you make an electric oven at home is quite difficult and expensive, then with muffle-type heating equipment this is quite feasible.

Independent production of the chamber for hardening of metal

Muffle furnace, which is quite possible to do yourself at home, allows you to harden different grades of steel. The main component, which will be required for the manufacture of this heating device, refractory clay. A layer of such clay, which will cover the inside of the furnace, should be no more 1 div.

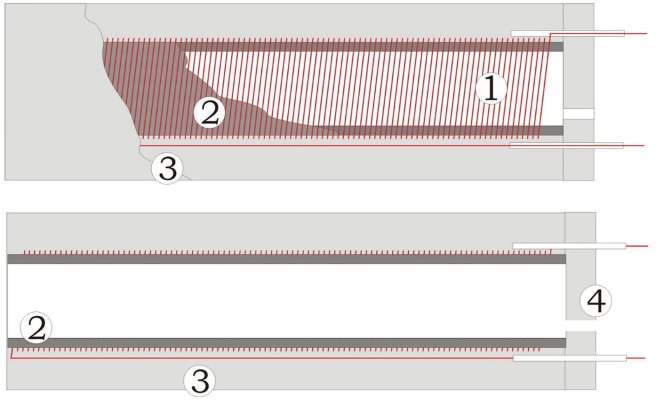

Scheme of the chamber for hardening metal: 1 - nichrome wire; 2 - inner part of the camera; 3 - the outer part of the camera; 4 - rear wall with spiral conclusions

In order to provide the future furnace with the necessary configuration and desired dimensions, it is best to make a form out of cardboard, impregnated with paraffin, on which refractory clay will be applied. Clay, mixed with water to a thick homogeneous mass, applied to the reverse side of the cardboard form, from which it will lag behind after complete drying. Metal products, heated in such a device, are placed in it through a special door, which is also made of refractory clay.

The chamber and the door of the device after drying in the open air are further dried at a temperature of 100 °. After that, they are subjected to firing in the oven, the temperature in the chamber which is gradually brought to 900 °. When they cool after firing, they must be carefully connected to each other, using metalwork tools and sandpaper.

Clay heater with a walled nichrome spiral

Nichrome wire is wound on the surface of the fully formed chamber, the diameter of which should be 0,75 mm. The first and last layer of such winding must be twisted together. Winding the wire on the camera, a certain distance should be left between its turns, which must also be filled with refractory clay, to eliminate the possibility of a short circuit. After a layer of clay, applied to provide insulation between turns of nichrome wire, dries up, another layer of clay is applied to the surface of the chamber, the thickness of which should be approximately 12 div.

The finished chamber after complete drying is placed in a metal housing, and the gaps between them are filled with asbestos crumbs. To provide access to the internal camera, the metal case of the furnace is hung by a door, finished inside with ceramic tiles. All available gaps between the structural elements are filled with refractory clay and asbestos crumb.

Ready-made homemade camera

The ends of the nichrome winding of the chamber, to which it is necessary to bring electric power, are deduced from the back of its metal framework. To control processes, occurring in the inner part of the muffle furnace, and measure the temperature in it with a thermocouple, in its front part it is necessary to make two openings, the diameters of which must be 1 and 2 see respectively. From the front of the frame such holes will be closed by special steel curtains. Homemade design, the manufacture of which is described above, that allows to harden metalwork and cutting tools in house conditions, working elements of stamping equipment, etc..

Independent production of such furnace (as well as hardening equipment of other type) allows not only to get a device, completely meets your needs, but also good to save, since serial models are quite expensive.