How to harden an ax at home: videos and tips

How to properly harden the ax at home? The urgency of this issue is due to the widespread demand for this tool. in addition, on the example of such a simple home tool, what is an ax, you can analyze in detail the nuances of several types of heat treatment - annealing, tempering and leave.

A good forged ax is able to cut a nail

Learn about it, that new ax, purchased from hand or in a hardware store, it is necessary to harden, quite easy: if the tool blade is very soft (which can be determined by its crumpling even when cutting small knots), means, it needs quality hardening. In that case, if cracks or painted blades appear on the working part of the ax during operation, he should be subjected to full leave.

З якої сталі виробляють сокири

To determine, how well made the hardening of the ax, you can use a regular file, which is not very worn and has a small notch. In that case, if the hardness of the working part of the ax is high, the file will slide easily on it, if average, then the tool will slightly remove the roughness, if low - the file will be good to take the metal. If the ax is hardened in accordance with generally accepted requirements, then the hardest is the sharp part (approximately 3 cm from the blade), and the metal in the other part of the tool is softer.

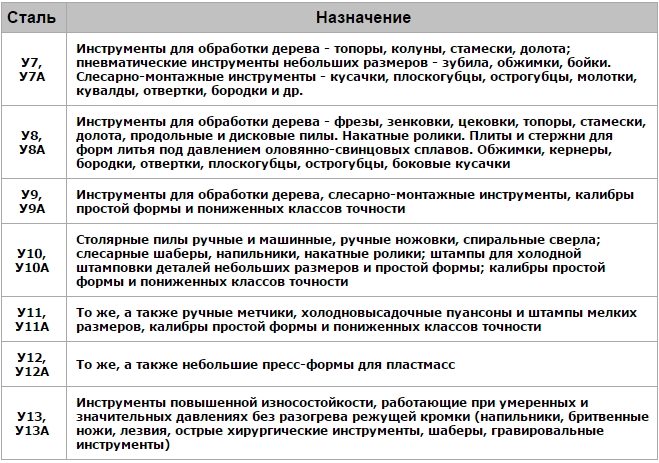

Purpose of tool carbon steels

Usually, axes are made of steels of these brands

Once you've found out, that the tool still needs to be hardened, need to be determined, what metal is it made of. Enterprises, working in full compliance with approved regulations (GUESTS), produce axes from certain steels, whose brands are specified in a special table. Naturally, that each of these alloys requires its own heating temperature and a certain cooling medium, which will provide the required quality of heat treatment. All similar parameters for each of the steel grades can also be found in special directories.

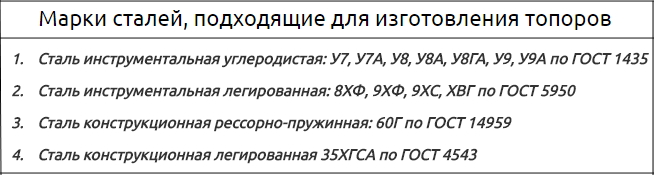

Annealing modes of carbon steels

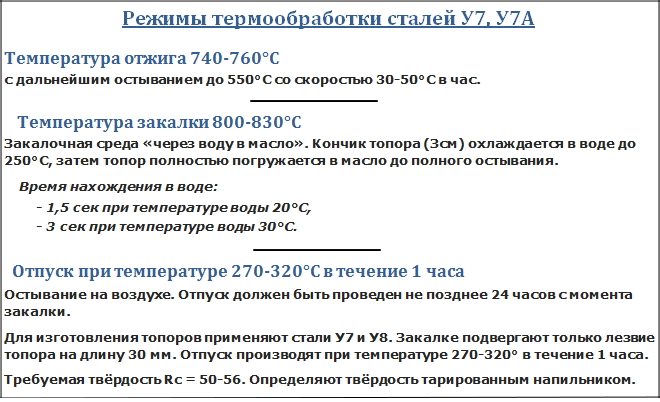

Heat treatment modes on the example of U7 and U7A steels

Of all types of steel, used to make axes, the most common can be considered instrumental steel alloys brands U7 and U7A. That is why we will consider as an example, how to harden the working part of the ax, made of U7 alloy.

The main stages of tempering axes

If you need to harden the ax at home, it is necessary to blunt its cutting edge, bringing its thickness to 1 mm. The very procedure of heat treatment of the tool, which is performed, including at home, consists of several stages.

Annealing

Annealing is the first stage of heat treatment not only of the ax, but also any other tool. The purpose of this technological operation, which can be done at home, is the purification of the structural memory of the metal. As a result, its internal structure is improved, removal of internal stresses and reduction of hardness. The essence of this procedure is, that the working part of the ax is heated to 740-760° and subjected to slow cooling to 550°, whose speed is 30-50 degrees per hour.

The simplest furnace for heating an ax is sheet metal with slots, on which bricks are laid and coal is poured

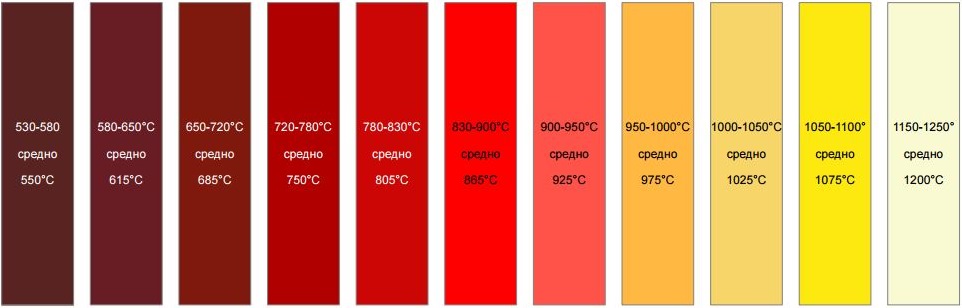

The most important point when performing annealing is the correct determination of the heating temperature. In such situations, you can focus on your experience or training videos, щоб визначити необхідний поріг нагріву за кольором розпеченій сталі. However, there is a more reliable way, which allows you to accurately determine the temperature, to which the steel was heated. It is quite simple to implement even at home. This method involves the use of a conventional magnet, which ceases to be attracted to the surface of the tool steel product at 768°. So, periodically applying a magnet to the surface of the ax, can be determined, that the heating process should be stopped, to proceed to the next stage of heat treatment.

The color of tool steel, heated to 768°, maroon, and if it is heated to 800-930 degrees, what is needed to perform hardening, it will become bright red. Look, how the colors of tool steel change depending on its heating temperature, it is possible on video, which is easy to find on the internet.

Hardening of steel (click to enlarge)

After the required temperature for annealing the ax, which needs to be hardened, achieved, it should be stopped heating. The ax is then left in the extinguished oven for ten hours for slow cooling.

Hardening

After the procedure, anneal the surface of the ax, which must be hardened, should be cleaned of scale. You can use a wire circle. When the surface of the ax is cleaned, it must be reheated, but already before 800-830°. The degree of heating can be controlled, стежачи за кольором сталі, which should become bright red.

Heat the ax "to red" in a makeshift brick kiln

After heating the ax must be cooled. To do this, use two media - water, heated to 30°, and oil. First of all the ax blade is cooled (width 3-4 cm), for which it is lowered into the water on 3-4 seconds. That in the used water the steam pillow was not formed, which will prevent efficient cooling, the blade must be moved intensively in the tank. The whole ax is placed in an oily cooling medium, it is important to monitor this, so that the oil does not ignite.

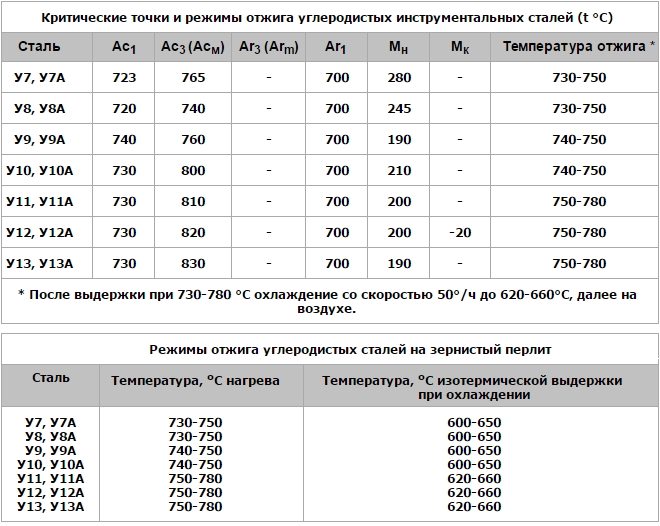

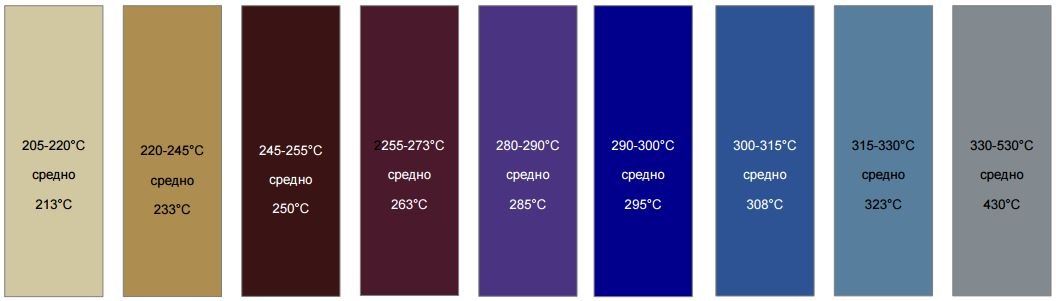

To reduce the hardness of the working part of the ax, which she will acquire afterwards, how to harden it, she must be released. Before performing such a technological operation, the surface of the ax must also be cleaned with a wire circle, which will control the degree of its heating, focusing on color variability.

Colors of variability of steel (click to enlarge)

Vacation

Release the hardened working part of the ax allows you to relieve internal stress, formed in the metal during hardening, and reduce the fragility of the material. You can use an ordinary oven to perform this procedure at home, heat up 300° and putting an ax in it 1 year (before you go on vacation, watch the relevant video). After keeping the ax in the oven, it is cooled, leaving outdoors. About that, that the holiday was held at the required temperature, will indicate the blue color of variability on the surface of the ax.

Photo of an ax, which have passed hardening, leave and stripping the blade

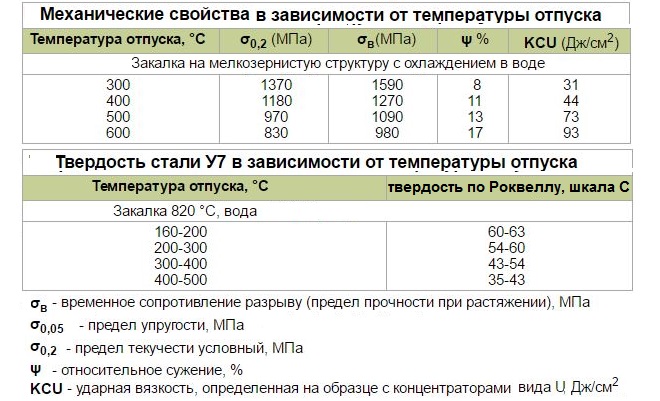

To make sure, that the working part of the ax became a little softer after the holiday, you can use a file, as described above. It should be borne in mind: the higher the temperature, in which this procedure is performed, the softer and more plastic the hardened metal will be. To select the holiday temperature, on which the hardness of the finished product directly depends, you can also use special tables.

Залежність механічних властивостей сталі марки У7 від температури відпустки

In conclusion, we suggest you watch a great video, in which the master tells in detail about all the main stages of self-tempering axes at home.