Brass and bronze: differences, storage, which is better, which lead to overheating of the gasoline or diesel engine

The question is, how to distinguish bronze from brass, not accidentally interested in many, after all, products made of these copper alloys are very similar in appearance. Meanwhile, deciding to use products made of such materials for a specific purpose, a distinction should be made between these two metals, as they have serious differences in many parameters.

These busts are very similar, but they are made of various copper alloys

What are bronze and brass

Bronze and brass are alloys, based on copper. More, some brands of such alloys are very similar in color, but their characteristics can have serious differences. In order to be well versed in the matter, in which cases to use brass, and in which - bronze, it is necessary to get acquainted in more detail with their properties and chemical composition.

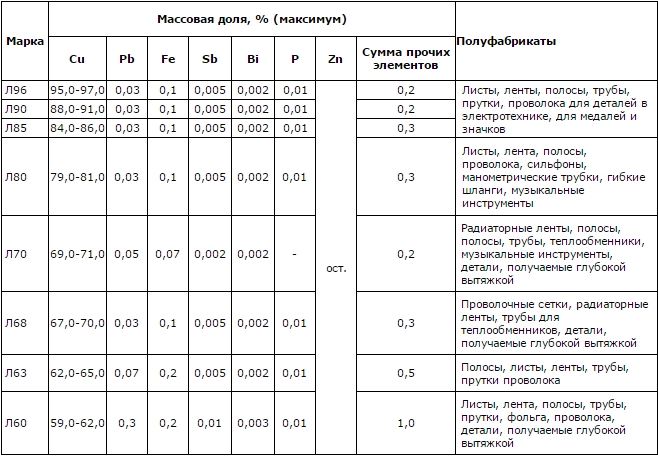

Chemical composition of simple brass

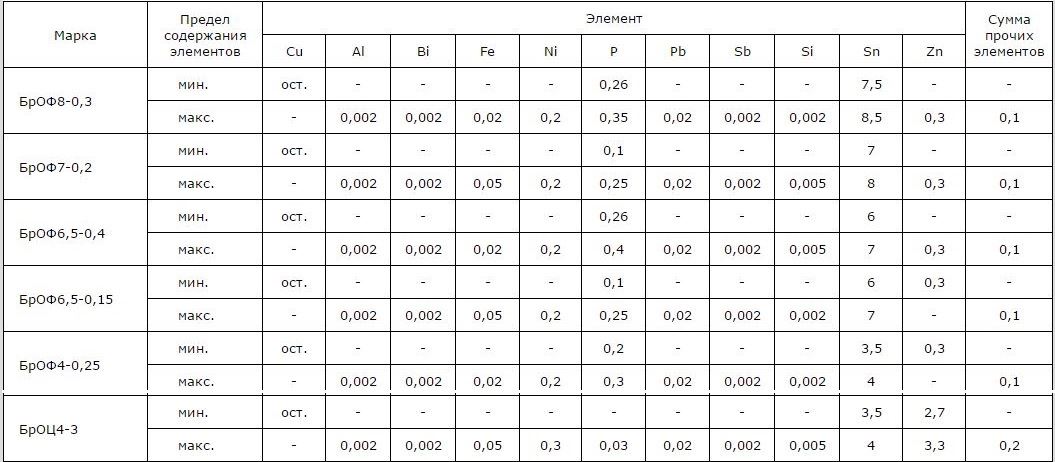

Chemical composition of tin bronzes (click to enlarge)

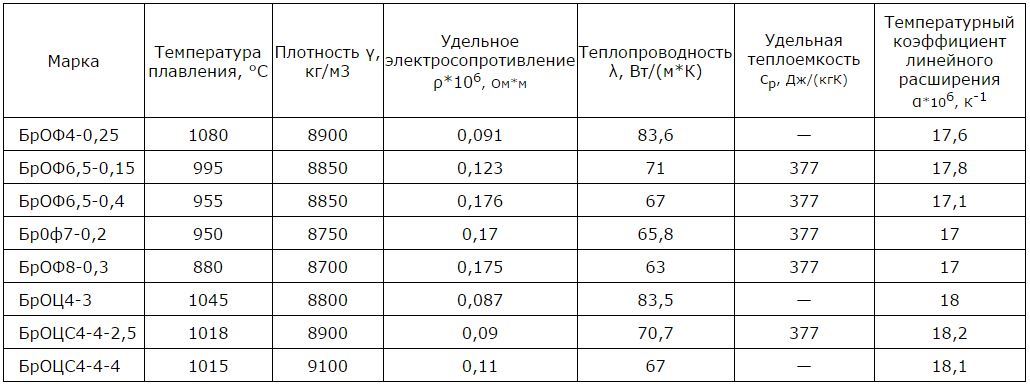

Such material, like bronze, used by mankind for several millennia, and its popularity is not diminishing. Initially, man learned to make bronze alloys, the basis of the chemical composition of which are copper and tin. Later, with the development of the metallurgical industry began to produce bronze, in which tin was replaced by other chemical elements - aluminum, lead, iron, silicon, beryllium, phosphorus, etc. Bronze of the first type became known as tin (they are often called bells, because they made bells), and the other - tinless. Changing the chemical composition of bronze leads to changes not only in its characteristics, but also colors.

Brass is also a copper alloy, but the main alloying element in it is zinc. The following elements may be present in the chemical composition of different brands of brass, like nickel, lead, iron, lead, manganese, etc., but their content is insignificant and necessary only for that, to give the finished alloy certain characteristics. It is known, that the ancient Romans were able to produce brass, who received it, mixing molten copper and zinc ore. More efficient production technology, which involves mixing molten copper and pure zinc, developed in England, and it happened in 1781 year.

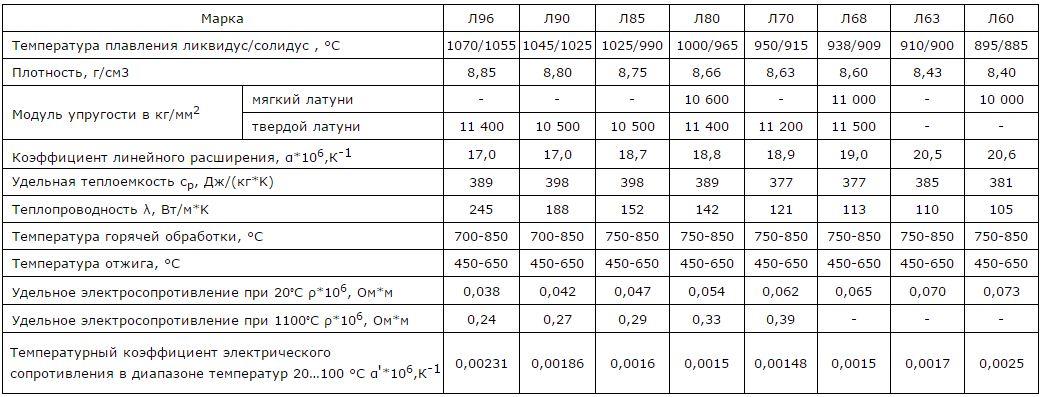

Physical properties of simple brass (click to enlarge)

Physical properties of tin bronzes (click to enlarge)

Brass for a long time, which has a beautiful light golden color, used for the manufacture of decorative items, including those, which were presented as gold. However, manufacturers could not ignore others, no less significant characteristics of this alloy, which include high corrosion resistance and abrasion resistance, plasticity, combined with a fairly high hardness and strength.

That is why brass, which also has good casting properties, began to be actively used not only for decorative purposes, but also for the manufacture of products, successfully used in various industries.

Comparative characteristics

The basis of bronze and brass, as mentioned above, is the same metal - copper. The difference between these alloys is their chemical composition and, in accordance, in characteristics, which they own. Naturally, that the differences between these copper alloys determine the scope of their application.

Because of that, that bronze is a stronger and more durable material, if you compare it with brass, bells have long been made of this material, sculptural compositions, elements of fences, landscape and interior constructions. That is also important, that many brands of this alloy are characterized by good fluidity in the molten state. This allows you to cast products from them, even in very complex configurations. Adding various chemical elements to the chemical composition of bronze, you can change its color in a fairly wide range, which is also of great importance in the production of decorative products.

This is a watch ring, judging by the color, rather yellow brass (bronze would be red). Scratches easily remain on the surface - also a sign of brass

Brass differs from bronze in higher ductility and, in accordance, less strength and durability, which limits the use of this alloy in many areas. in addition, brass is less resistant to aggressive environments, in particular salty sea water, which does not allow the use of brass products in shipbuilding, where bronze is used very actively and successfully.

There is also a noticeable difference in the color of these alloys and their internal structure. Any experienced specialist can tell, how to distinguish brass from bronze: it is enough to look at the fracture of products from these alloys. Brass at the break has a lighter color and a pronounced fine-grained structure, while bronze is easily identified by the dark brown color of the fracture and the coarse-grained internal structure.

Fracture of the bronze clutch

Summarizing all the above, we can distinguish the following differences between brass and bronze.

- The main alloying element in bronze is tin, and in brass - zinc. Both alloys are based on one metal - copper.

- Bronze (even with a classic chemical composition) perfectly resists the influence of aggressive environments, in particular salty sea water. In order to improve the corrosion resistance of brass, additional alloying elements must be introduced into such an alloy.

- Strength and antifriction characteristics of bronze are also better, than in brass. Such qualities significantly expand the scope of application of bronze alloys, from which not only strong and durable decorative elements are made, but also responsible parts for use in various industries. Brass is more often used for the production of bimetallic elements ("Steel - brass"), demonstrating high resistance to the formation and development of corrosion processes.

- Bronze products have a dark brown color and large grain at the break, and brass - yellow-gold and fine-grained structure. This difference in color and internal structure is easy to identify, from which alloy the product is made.

- Bronze, as well as brass, although they are based on such a metal, like copper, are divided into different categories. So, bronze can be tin or tin-free, while brass is two - or multicomponent.

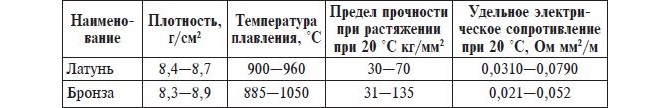

Comparison of properties of brass and bronze

Bronze and brass, the melting point of which is lower, than in copper, can be used to make various products at home. However, for this, naturally, it is necessary to stock up on appropriate equipment and to study well the technology and rules of such technological operation, as casting.

And finally a couple of videos about heat treatment of bronze at home.