Stainless steel processing: digestion, grinding, polishing and others

Stainless steel processing, which can be performed using various techniques and technologies, allows not only to endow products from this metal with the necessary parameters and quality characteristics, but also give their surface an attractive appearance. Properly selecting and using different processing methods, from stainless steel alloys produce products for various purposes, which fully meet the requirements proposed to them.

Mechanical treatment of stainless steel with power tools allows you to quickly remove from the surface roughness

Grinding and polishing (hot pressing)

Due to the whole list of advantages, stainless steel is equally successfully used for the manufacture of products as a practical, and purely decorative purposes. To give their surface an attractive appearance, and to achieve the required level of roughness, they are often ground and polished, which are denoted by one common term - satin. These processing methods got this name because of that, that after their performance the surface of a stainless steel reminds on the texture satin or satin fabric.

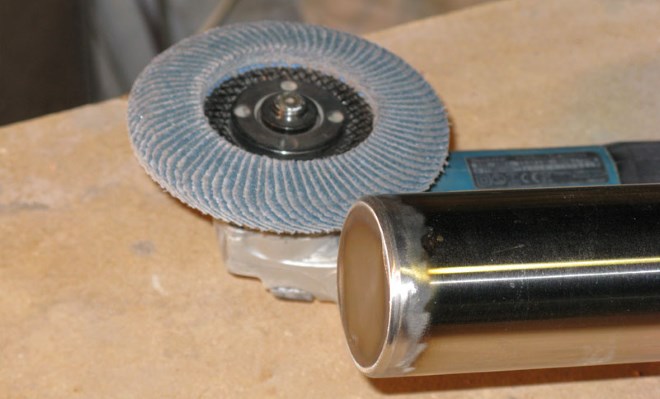

Processing of a welding seam on stainless steel begins with deduction of a surface to small lines by means of the Bulgarian with a petal circle

In addition to giving the surface of the stainless steel product an attractive appearance, grinding allows to eliminate surface defects of metal or to make them practically imperceptible. Like grinding, and polishing of stainless steel can be performed manually or with special devices, operating on electric or pneumatic drive.

Of the most common devices, used for grinding, should be highlighted:

- pneumo file of tape type;

- drum-belt grinder;

- other devices, which involve the use of sanding belts.

At home, grinding is often done manually, which may require sanding sheets or tools, which are called polishes. In contrast to the conditions of home workshops, at industrial enterprises grinding of stainless steel is performed using special equipment.

Grinding of stainless steel begins with the grain 180, then 320 and 600, and finish polishing with a felt circle

When a hand grinding tool is used to grind stainless steel, such processing is performed in the following sequence.

- If the stainless steel parts have been welded together, then burns and welds are removed from their surface.

- That part of the surface, which will be the first to be ground, should be limited, using aluminum adhesive tape (it is glued in two or three layers).

- Surface area, which is not sealed with protective tape, is processed by means of reciprocating movements of a polishing, at the same time pressure, which is done on the tool, should not be too strong.

- After achieving the desired result of grinding with aluminum tape is sealed already processed part, and that area is subject to processing, which borders on it.

In those cases, when the use of polishing is impractical, grinding sheets are used for processing stainless steel. To properly select such a grinding tool for its grain size, use trial drafts.

Lathes can also be used for grinding and polishing stainless steel, on which special circles are established. It is possible to carry out such finishing operations with use of the lathe as in production, and at home, if such equipment is in the equipment of your home workshop. Even the simplest models of lathes can be used to effectively perform these technological operations.

Метод травлення

Etching is a fairly common method of processing stainless steel products. Such a technological operation, which allows you to remove from the surface of the stainless steel product various defects, used to eliminate traces of welding, after heat treatment, and also processing of details by methods of plastic deformation. in addition, digestion allows you to remove colors of variability from stainless steel, and also updates the passive layer on it, which protects the metal from the effects of high temperatures.

Aqueous solutions of acids or molten alkaline media are used to perform digestion in industrial conditions. When using acidic media, digestion is performed in two stages, the first of which involves the treatment of stainless steel with sulfuric acid solution, and the second - a solution based on nitric acid. To perform alkaline digestion, the stainless steel product is placed in a melt of caustic soda, which, without changing the structure of steel, effectively destroys the oxide film, formed on its surface.

It is possible to return a corrosion-proof metallic shine to a stainless surface and to restore loss of chromium after welding by means of etching paste

At home, digestion is performed with the help of special pastes, having a jelly-like consistency. Using such pastes, should be borne in mind, that in their composition, except fluorine and nitrogen, include hydrochloric acid, as well as chlorides, which pose a danger to human health, therefore, they should be handled with extreme caution.

Stainless steel etching paste should only be applied to thoroughly cleaned and degreased parts, for which it is washed with warm water and treated with any available detergent. After a short exposure (from 10 to 60 minutes) pickling paste is washed off, for which ordinary running water is also used. Apply paste for etching stainless steel with acid-resistant brushes and special plastic spatulas.

Large areas of stainless surfaces are treated with etching sprays using jet spraying

Today, pickling pastes of the following brands are very popular, which have already proved their high efficiency.

SAROX TS-K 2000

This paste provides reliable protection of stainless steel from the negative effects of temperature, and eliminates all surface defects of welded joints. Which is convenient, this paste, which effectively processes the steel product just for 10 minutes, can be used for etching and vertically arranged surfaces.

Avesta BlueOne

With this paste, the time of its impact on the surface of the product should be approx 45 minutes, it is possible not only to eliminate small defects of welded joints, but also to clean stainless steel from traces of corrosion, give it a nice metallic shine. Choosing such a composition, should be borne in mind, that it can be used for processing stainless steel only at an ambient temperature not lower +50.

Stain Clean (ESAB)

It is completely ready to use pickling paste, which does not require special conditions of use and is highly efficient.

Other ways of processing stainless steel products

Ware, made of stainless steel, often subjected to chrome plating, that allows:

- give them an attractive appearance;

- increase resistance to mechanical influences (friction, blows, etc.);

- significantly increase their corrosion resistance.

Meanwhile, the quality of the chrome plating operation can be performed only in production conditions, as its implementation requires not only special consumables and special equipment, but also the availability of relevant knowledge and skills.

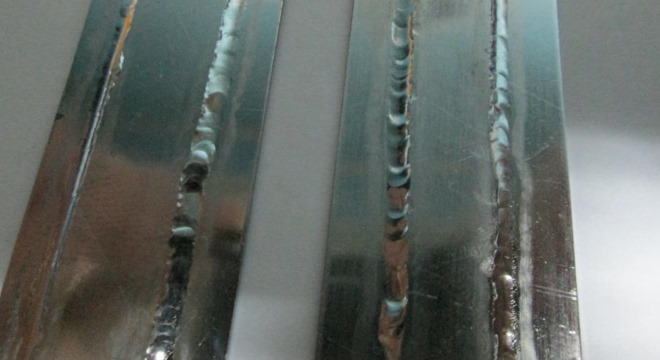

The photo shows the welds of stainless steel after processing 85% orthophosphoric acid - the result of digestion looks no worse than mechanical polishing

You can perform another operation at home, that allows to give to a surface of a product from a stainless steel an attractive appearance, - blueing. Such processing can be performed by one of the following methods:

- acidic effects;

- use of alkalis;

- application of thermal influence.

Of course, the simplest and most accessible method of finishing steel products is their painting, which can also be performed using different technologies and consumables.