Processing of openings (drilling, waiting, deployment, etc.) and tool

Hole processing is a number of technological operations, whose purpose is to prove the geometric parameters, as well as the degree of roughness of the inner surface of the pre-drilled holes to the required values. Open up, which are processed by means of such technological operations, which can be pre-obtained in solid material not only by drilling, but also by casting, pushing and other ways.

Treatment of the drilled hole with a cylindrical countersink

The specific method and tool for processing holes is selected in accordance with the characteristics of the desired result. There are three ways to process drilling holes, deployment and countersinking. In turn, these methods are divided into additional technological operations, which include reaming, checking and countersinking.

To understand the features of each of the above methods, it is worth considering them in more detail.

Drilling

To process holes, they must be obtained in advance, for which you can use different technologies. The most common of these technologies is drilling, is performed using a cutting tool, which is called a drill.

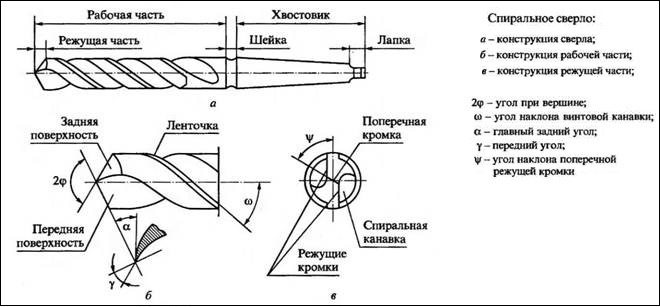

The main parts of a twist drill

With the help of drills, are installed in special devices or equipment, in solid material can be obtained as through, and blind holes. Depending on the tools and equipment used, drilling can be:

- manual, which is performed using mechanical drilling devices or electric and pneumatic drills;

- machine tool, carried out on specialized drilling equipment.

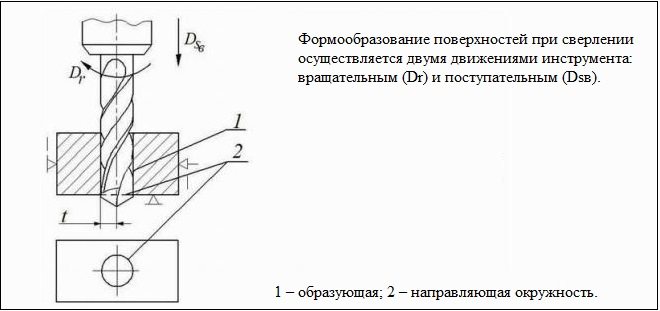

Physics of drilling holes

The use of hand drills is advisable in those cases, cars open, whose diameter does not exceed 12 mm, that it is necessary to receive in preparations from materials of small and average hardness. To such materials, in particular, include:

- structural steels;

- non-ferrous metals and alloys;

- alloys of polymeric materials.

If the workpiece needs to make a hole of larger diameter, as well as to achieve high productivity of this process, it is best to use special drilling machines, which can be desktop and stationary. The latter, in turn, are divided into vertical and radial drilling.

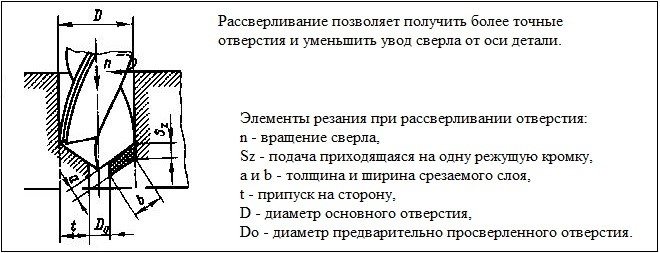

Drilling - a type of drilling operation - is performed for this purpose, to increase the diameter of the hole, made in the workpiece before. Drilling is also performed with drills, the diameter of which corresponds to the required characteristics of the finished hole.

Physics of drilling holes

This method of processing holes is undesirable to apply to those of them, which were created by casting or by plastic deformation of the material. It has to do with that, that parts of their inner surface are characterized by different hardness, which is the cause of uneven distribution of loads on the axis of the drill and, in accordance, leads to its shift. Formation of a scale layer on the inner surface of the hole, created by casting, as well as the concentration of internal stresses in the structure of the part, made by forging or stamping, may be the reason, that when reaming such workpieces, the drill will not only shift from the desired trajectory, but will break.

When performing drilling and reaming, you can get surfaces, the roughness of which will reach Rz 80, while the accuracy of the parameters of the formed holes will correspond to the tenth quality.

Countersinking

By countersinking, performed using a special cutting tool, the following tasks are solved, related to the processing of holes, obtained by casting, stamping, forging or by other technological operations:

- bringing the shape and geometric parameters of the existing hole in line with the required values;

- increase the accuracy of the parameters of pre-drilled holes up to the eighth quality;

- treatment of cylindrical holes to reduce the degree of roughness of their inner surface, which when using such a technological operation can reach the value of Ra 1,25.

When countersinking, less cutting force is applied, than when drilling, and the hole is more accurate in shape and size

If such processing it is necessary to subject an aperture of small diameter, then it can be performed on desktop drilling machines. Countersinking holes of large diameter, as well as processing of deep holes are performed on stationary equipment, which is installed on a special foundation.

Manual drilling equipment for countersinking is not used, as its technical characteristics do not allow to provide necessary accuracy and roughness of a surface of the processed opening. Varieties of countersinking are the following technological operations, as tsekovanie and countersinking, in the performance of which various tools are used for processing holes.

Countersinks conical on metal

Experts give the following recommendations for those, who plans to perform countersinking.

- Countersinking should be carried out in the process of the same installation of the part on the machine, in which the hole was drilled, at the same time from processing parameters only type of the used tool changes.

- In those cases, when countersinking is an untreated hole in the parts of the housing type, it is necessary to control the reliability of their fixation on the desktop of the machine.

- Choosing the value of the allowance for countersinking, it is necessary to be guided by special tables.

- Modes, on which countersinking is performed, should be the same, as in the implementation of drilling.

- When countersinking, the same rules of labor protection and safety must be observed, as well as when drilling on metalwork and drilling equipment.

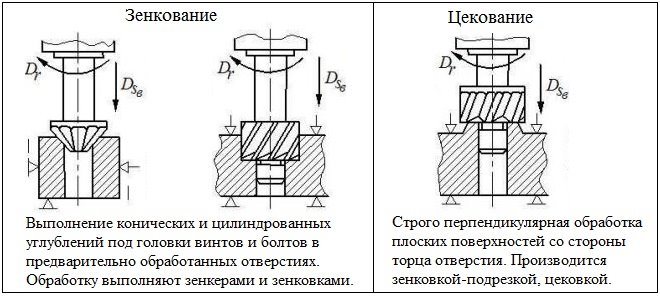

Countersinking and checking

When performing countersinking, a special tool is used - countersinking. Only the upper part of the hole is processed. Apply such a technological operation in those cases, when in this part of openings it is necessary to form deepenings for heads of fastening elements or simply to remove from it a chamfer.

What is the difference between countersinking and tsekovanie

When performing countersinking, certain rules are also followed.

- Perform this operation only after that, as the hole in the part will be completely drilled.

- Drilling and countersinking are performed in one installation of the part on the machine.

- For countersinking set small turns of a spindle (not more 100 rpm) and use manual tool feed.

- In those cases, when countersinking is performed with a cylindrical tool, the diameter of the pin which is larger than the diameter of the machined hole, the work is performed in the following sequence: the hole is drilled first, whose diameter is equal to the diameter of the pin, countersinking is performed, then the main hole is drilled to the specified size.

The purpose of this type of processing, as tsekovanie, there is a cleaning of surfaces of a detail, which will come in contact with the nuts, bolt heads, washers and snap rings. This operation is also performed on machines and with the help of tsekovki, for installation of which on the equipment mandrels are applied.

Deployment

Holes are subjected to the deployment procedure, which were previously obtained in detail by drilling. The element processed using such technological operation can have accuracy, the degree of which reaches the sixth quality, as well as low roughness - up to Ra 0,63. Sweeps are divided into rough and finished, they can also be manual or machine.

Manual cylindrical sweeps 24H8 0150

Recommendations, which should be followed when performing this type of processing, are as follows.

- Allowances in the diameter of the machined hole are selected according to special tables.

- When using a hand tool, which is rotated only clockwise, first perform a draft, and then a clean deployment.

- Processing of steel parts is performed with the obligatory use of coolant, cast iron - dry.

- Machine deployment is carried out immediately after drilling on the machine - from one installation part.

- Special calibers are used to control the quality of the result.