Patination of copper and brass at home (blacking, aging)

Patination of copper, as well as other methods of its decorative finishing (including at home) allow to make products from this metal more attractive, give them a touch of noble antiquity. Objects can be subjected to such processing, made not only of copper, but also from such its alloys, both bronze and brass.

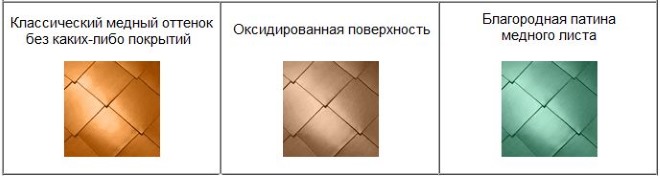

Using different methods of patination of copper alloys, you can achieve completely different shades

Patination and oxidation

The surface of many metals (and copper is among them) when interacting with ambient air and various chemicals begins to be covered with a thin layer of oxides and oxides. Such a process, which also changes the color of the metal surface, called oxidation. For the most part, the process of metal oxidation occurs naturally, but people have learned to summon it artificially, at work or at home, which is done to give the product an aged look.

Oxidation should not be confused with patination - a process, the essence of which is, that a thin layer of sulfur or chloride compounds is formed on the surface of the metal when interacting with various chemical elements. Patination, which, as well as oxidation, accompanied by discoloration of copper and bronze, can also be performed artificially, using special compounds for this purpose.

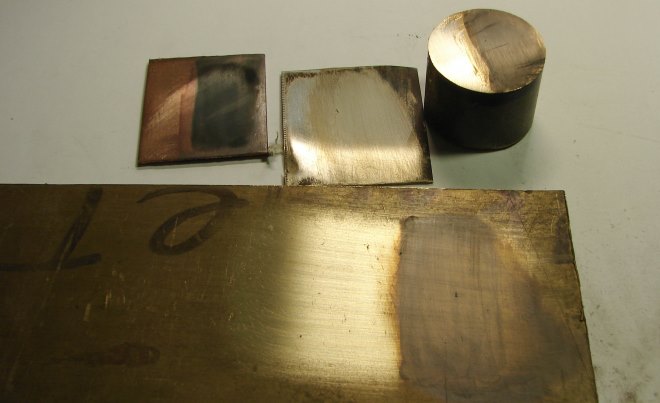

Aging of copper occurs over time naturally or immediately when treating the surface with any drugs

If under natural conditions the process of oxidation and patina coating of copper or bronze can take years, then when using special solutions patination occurs in a very short period of time. The surface of the product, placed in such a solution, literally changes its color before your eyes, acquiring a touch of noble antiquity. Using different chemical compounds, it is possible to carry out such procedures in industrial and even in house conditions, like blackening copper, patination of objects made of copper and bronze, blackening of brass.

Preparation for processing

Deciding to perform patination or oxidation, you need to not only study the question carefully, how to age brass, bronze or blacken copper, but also to provide the necessary security measures. The vast majority of chemical compounds, which are used to carry out such procedures, are very toxic and emit vapors, which pose a significant risk to human health. Therefore for storage of such substances as in industrial, and at home you should use dishes with well-ground corks, which will help prevent the ingress of toxic fumes into the ambient air.

Keep chemicals out of the reach of children

The procedure itself, carried out to change the color of the surface of the product under the influence of chemicals, should be performed in a special cabinet, to which the exhaust ventilation is connected. It should be borne in mind, that the door of such a cabinet in the process of oxidation or patination should be slightly open, which will provide effective extraction of harmful fumes from its inner part.

Copper products, brass and bronze should be thoroughly cleaned before patination, degrease and rinse in warm water. After the patination or oxidation procedure, the treated items are also washed and placed in sawdust for drying.. The use of sawdust is a more gentle method of drying, as performing such a procedure with a fabric material can damage the thin film of the formed patina, which is not yet fixed with varnish. in addition, with the help of fabric after patination it is almost impossible to qualitatively remove moisture from the recesses on the relief surfaces, and sawdust is easily removed.

The varnished surface can be polished with a felt nozzle

Changes in the color of copper and its alloys from gray to black

Gray, dark gray or black color of copper and its alloys makes the appearance of the product more attractive and presentable. To get these colors, the degree of saturation of which can be adjusted, requires the composition "sulfur liver" used for more than ten years. He got his name because of that, that in the process of cooking it must bake, that is, turn into a baked mass.

To make such a composition for patination at home, the following steps must be performed:

- one part of powdered sulfur is mixed with two parts of potash;

- the resulting mixture is placed in a can, which must then be put on fire;

- waiting for the powder to melt and began to sinter, it is necessary to maintain this process throughout 15 minutes.

Soda and sulfur will be needed to make sulfur liver

Blue-green flames may ignite on the surface during the sintering process, which can not be knocked down, as it will not worsen the quality characteristics of sulfur liver. After sintering and complete cooling, the resulting mass should be ground to a powdery state. This powder, if you put it in a glass jar with a tight-fitting lid, can be stored long enough.

In order to perform the patination of various metal alloys with the help of sulfur liver, use several basic methods.

method no. 1

This method involves the use of an aqueous solution of sulfur liver. With its help you can change the color of products, made of such materials:

- copper;

- Silver;

- bronze and brass.

Colors, which can be used to paint the surface of products using this method, also differ:

- copper and silver - purple, blue (get very difficult), gray, brown-gray, black;

- brass and bronze - light gold.

Sample solution on copper, bronze and brass give different effects

If you didn't know before, how to age copper and form a strong patina film on the surface of this metal, characterized by a rich black color, use this method. For its implementation, the copper product is contained in the solution, consisting of a liter of water and 1-20 grams of sulfur liver powder.

To paint copper in light gray, the solution is prepared according to another recipe: v 1 liter of water is dissolved by 2-3 grams of sodium chloride and sulfur liver. A copper product is placed in the resulting solution, the change in color which should be closely monitored. Once the color of the metal acquires the desired tone, patina subject must be washed with water and dried in sawdust.

The duration of processing of copper jewelry solution depends on the desired effect of blackening

method no. 2

You can also use a solution to patina copper, prepared according to this recipe: in saturated aqueous solution of copper sulfate add ammonia and do so until, until the liquid becomes clear and bright blue. The cleaned and defatted processed product is placed in such solution for some minutes, then it is removed and subjected to slight heating. After such manipulations, the copper should acquire a rich black color.

method no. 3

To use this method, which also allows quality cave copper even at home, the processed subject needs to be cleaned up by means of a thin sandpaper. Do not touch the cleaned surface with your hands, so that it does not form fat stains. After preliminary preparation for patination, the item is treated with a solution of platinum chloride or completely immersed in it. In such a solution, if it does not cause an acid reaction, you can add a small amount of hydrochloric acid.

method no. 4

Form a strong oxide film on the surface of the copper product, characterized by a rich black color, allows it to be immersed in the composition, prepared from nitric acid and metallic copper. To change the color of the copper part was more intense, this solution can be further heated.

Getting patina of other colors

For formation on copper of an oxide film of other color it is possible to use even in house conditions one of the following methods.

Red-brown

To obtain a red-brown oxide film, the copper product is placed in the composition for a few minutes, made from one part of copper sulfate, one part zinc chloride and two parts water.

One example can be seen in the example, how the shade changes depending on the length of stay in solution

Gamma from light brown to black

To get such a patina, an object made of copper must be placed in the solution, consisting of one liter of water and 20 grams of ammonium sulfide. Changing the heating temperature of the processed product before patination, you can adjust the intensity of staining.

Light brown

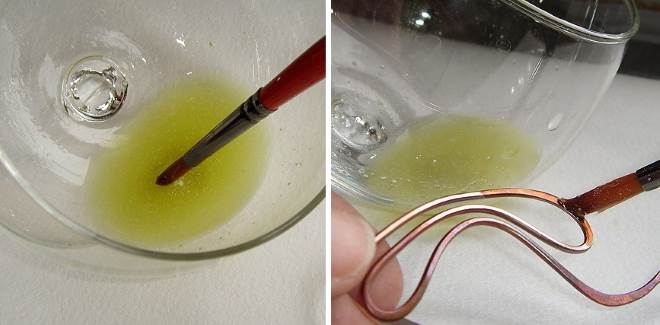

To add a light brown color to the surface of the copper product, it must be treated with a mixture of sodium chromium (124 G / liter), nitrogen (15,5 G / liter) and hydrogen chloride (4,65 G / liter) acids, 18-percentage of ammonium sulfide ( 3-5 G / liter). This solution is applied with a brush and kept for four to five hours.

Cover the surface of the part, until you reach the desired shade

Gamma from dark- to warm brown

To obtain a surface of this color copper part on 5-25 minutes placed in hot solution (90-95°), Which includes ammonium persulfate (9,25 G / liter) and caustic soda (50 G / liter). The procedure is repeated to achieve the desired effect 2-3 times.

Gamma from olive to brown

Copper product for patina on 10-15 minutes placed in a heated aqueous solution of Bertoletto salt (50-70 G / l), copper nitrate (40-50 G / l) and ammonium chloride (80-100 G / l).

Noble white and green

The most popular method of creating a green patina is to immerse a copper object in the composition, made from water (1 liter), copper sulphate (50 G) and potassium permanganate (5 G).

There are many more methods, allowing to create a patina of various shades of green, brown and black, golden, golden brown with crimson variability and others.