Internal starting system of the internal combustion engine: device and principle of operation

The starting system of the car engine carries out primary rotation of a cranked shaft of the internal combustion engine, resulting in the ignition of the fuel-air mixture in the cylinders and the power unit begins to work independently.

The main task of the starting system is to turn the cloned, allowing the piston to perform the necessary to ignite the compression charge of the mixture in the cylinders. Then the fuel ignites (from an external source in gasoline engines, from strong compression and heating in diesel).

Then the crankshaft begins to rotate independently, that is, the engine starts, crankshaft speed increases, shaft rotation becomes possible due to the conversion of thermal energy of fuel combustion into mechanical work. As soon as the crankshaft speed reaches a certain frequency, the startup system automatically shuts down.

In this article we will consider, how the electrical engine start system works, of which basic elements it consists, as well as talk about it, which are still engine start systems, in addition to electrical solutions.

Engine starting system: design features and the principle of operation of the electric start of the internal combustion engine

Let's start with that, that at an early stage the car's engines were started manually. A special winding handle was used for this purpose, which was inserted into a special hole, after which the driver independently carried out a cranked shaft.

Then came the electric starter system, which at first was not entirely reliable. For this reason, on many models, electric start was combined with the possibility of manual start, which made it possible to start the engine in case of problems with starting. Then such a scheme was completely abandoned, as the overall reliability of electrical systems has increased significantly.

so, startup system (often called a starter engine start system) consists of mechanical and electrical components and units. As already mentioned, the main task is to turn the engine to start.

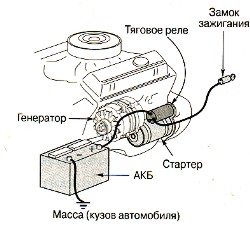

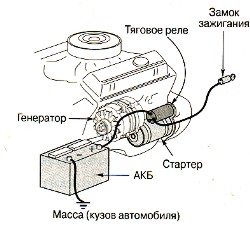

The main elements in the scheme of electrical start of the engine are:

- starter circuit;

- starter;

- battery;

In a nutshell, starter circuit is actually an electrical circuit, by which electric current is supplied from the battery to the starter. Such a circuit includes a wire, which connects the battery and the starter, "Mass" on the car body, as well as various terminals and connections, followed by the starting current.

As for the battery, the main task is to provide the necessary voltage for the starter. Importantly, that the battery had the required capacity and charge level is not lower 70%, which allows the starter to scroll the crankshaft of the engine with the required frequency to start.

The starter is an electric motor. A gear is mounted on the starter shaft, which, after applying voltage to the starter, engages with the ring gear on the engine flywheel. This is how the transmission of torque from the starter to the engine crankshaft is realized.

We will note still, that the starter consumes a large starting current. A low-current switch is used to turn the starter on and off, better known as the ignition lock. This element controls a special relay, as well as starter locking switches (in the presence).

Let's return to the general device of elements of system. As already mentioned, starter with traction relay is a DC motor. The starter consists of a stator, which is the case, rotor (anchor), as well as brushes with a brush holder, traction relay and drive mechanism.

The traction relay provides power to the starter windings, and also allows the drive mechanism to work. The specified traction relay includes a winding, anchor, contact plate. Electric current is supplied to the traction relay through special contact bolts.

The drive mechanism is required to transmit torque from the starter to the crankshaft. The main structural elements are the drive lever or fork, which has a flood clutch, damping spring, as well as overtaking clutch and drive gear. This gear is engaged with the flywheel ring gear, which is mounted on the crankshaft. The ignition lock after turning the key to the "start" position is responsible for supplying direct current from the battery to the starter traction relay.

The principle of operation of the electric starting system of the internal combustion engine

The electric starting system is based on different types of motors (two-stroke and four-stroke, petrol, diesel, rotary-piston, gas, etc.)

The general principle of operation is as follows:

After, as the driver turns the key in the ignition, electric current from the battery is supplied to the contacts of the traction relay (on the retracting starter). At that time, when the current begins to flow through the windings of the traction relay, the anchor is retracted. The specified anchor moves the lever of the drive mechanism, as a result gearing of a leading gear wheel and a gear crown of a flywheel is carried out.

In parallel, the armature closes the relay contacts, due to which the power supply of the stator and armature windings is realized. This allows the starter to rotate, transmitting torque to the crankshaft.

After starting the engine, the crankshaft speed increases. At this point, overtaking the clutch is triggered, disconnect the starter from the engine, while the starter still continues its rotation. Then with the help of the return spring of the traction relay there is a reverse movement of the armature. This allows you to return the drive mechanism to the opposite position.

By the way, if we talk about the various standard starter locks when starting the engine, such solutions occur, however, not on all car models. The main task is to increase the comfort of operation and safety. If simple, the starter will not work, until the driver squeezes the clutch or engages neutral before starting the engine.

We also recommend reading the article about it, why the voltage "fails" when starting the engine. In this article you will learn about the causes of voltage drops in the onboard car network, as well as what points and nuances should be considered when diagnosing such problems.

The presence of such a lock avoids jerks and accidental movement of the vehicle, which often happens, when the driver starts the engine from the starter with the transmission engaged.

Engine air start system

An air launch system is another solution, which allows you to scroll the crankshaft of the engine. Compressed air is used to start the motor. At the same time such pneumatic equipment, usually, not used on cars and other equipment, however, starting systems of this type can be found on stationary internal combustion engines.

If we talk about the design, the device of the system of air starting of the engine provides existence of the following elements:

- air balloon;

- solenoid valves;

- oil sump;

- Check valve;

- air distributor;

- starting valves;

- pipelines;

The principle of operation of the air start system of the internal combustion engine is based on that, compressed air in the air cylinder under pressure is fed into the distributor box, then passes through the filters into the gearbox and enters the solenoid valve.

Next you need to click "start", then the valve opens, then air from the air distributor passes through the starting valves and enters the engine cylinders, creating pressure and untwisting the crankshaft. When the speed reaches the desired frequency, the engine starts.

Let's add, that such power plants are additionally equipped with an electric starting system from the starter, which allows you to start the unit in that case, if with air start, which is the main way, there are any problems or a breakdown.

Tips and tricks

It is necessary to consider, that the electric starting system of engines usually provides that, that the power of the battery and the starter will be almost the same. This means, that the battery voltage varies greatly with that current, which consumes the starter.

In simple words, the efficiency and ease of starting the engine is strongly influenced by the general condition of the battery, battery temperature, charge level, as well as the serviceability of the starter and starter circuit. The following symptoms allow you to diagnose some problems at an early stage, as a clear attenuation of the dimensions and illumination of the instrument panel at the time of starting the engine.

We also recommend reading the article about it, why the radio turns off when you start the car engine. In this article you will learn about the reasons for disabling the GU during startup, and in which cases such disconnection is a sign of possible malfunctions.

As you know, the brightness of the lamps depends on the voltage in the onboard network. At the same time the starting system normally works should not strongly "sink" voltage. Note, that normally reduce the brightness of the dashboard and, in some cases, restart the radio, however, the brightness should not be greatly reduced.

If the brightness of the lighting does not change, the crankshaft also does not rotate, it is often appropriate to talk about a break in the chain. If the starter turns slowly and the lighting is almost off, then the problems may be with the starter itself (example, wedging), and with an electric circuit or battery.

We will note still, that in case of startup problems, which are related to the starter, some drivers are used to knocking on this device. The point is, what are the knocks on older starter models (example, on the "classic" VAZ) in some cases allowed to move the starter brushes, rotor, etc.. In this way it was possible to restore the device for a short time.

It is important to understand, that modern starters have permanent magnets in their device. These magnets are quite fragile, that is, after hitting the starter, they split.

Eventually, the whole magnet breaks down. Moreover, such magnets on some models of starters can be simply glued to the case. In accordance, if you hit the body hard, the broken off parts of a magnet get on a rotor or in the field of installation of bearings, completely disabling the starter.