Joiner's clamps: what it is, description and application F- and G-shaped, tape and pipe clamps

Many home craftsmen have questions about clamps. What are they used for, how they are used and which are better? For those, who does not know, it is worth noting, that the clamp is a clamp for temporary positioning of details for their further fastening. Clamps come in different types and are designed for different tasks. Those, who is engaged in carpentry, knows, that the more you use such clamps, the more applications they have. Therefore in a workshop clamps of various types and the sizes should always be reliable and convenient in work.

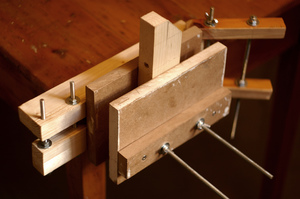

Joiner's clamps - general description

Joiner's clamps are made of wood and metal. Having installed such a device on the surface, you can work with both hands.

The simplest hand clamp consists of a main frame and movable elements, which are equipped with clamps in the form of screws or levers. They not only fix the moving part, but also regulate the compression force.

There are lever devices, which are based on both the axis system, and levers. They are often called clamps or clamps. With their help it is possible to make fast fixing of preparation. All you need to do is make a little effort to move the handle, and a decent clamping force will be created instantly.

Types of metalwork and carpentry clamps

Models of clamps differ in mechanisms, therefore divided into such classes:

- angular;

- mounting;

- screw;

- manually;

- clamping.

When choosing such a device, you must pay attention to the distance, on which clamps move apart and on a working course. The most practical are clamps, having the highest indicators listed above. With their help you can work with large products (from 20 to 350 mm).

tape clamps

It is difficult to imagine work in a carpentry workshop without tape clamps. The basis of this device is a nylon or leather belt, by means of which the clamping force is transmitted to the connected parts.

Tape clamps will provide uniform pressing force and strong fixing of any preparation. They can be used to make or repair frames, wooden chairs, countertops, aquariums and more. This versatile device is easy to connect, drill and glue at a precisely set angle fixed parts of the structure.

The length of the tape in the belt clamps is as follows, that it can wrap the body of any oversized design, tightening all connections at the same time. There is no risk of damaging the tightening parts, as metal parts of a tape clamp will not concern them.

However, in some cases it is not very convenient to work with this type of clamps. It has to do with that, that when installing a corner on one side, on the other he may fall. exept this, you cannot increase or decrease the pressure on one specific plane or axis.

When using tape without corners, you can easily damage the edge of the workpiece. Therefore, in addition to the tape clamp, it is recommended to buy special corners, which will significantly expand the functionality of the clamp.

pipe clamps

Pipe clamps are made of water pipes? or? in, on which the fixed emphasis and a movable sponge are screwed. You can make devices of any length, having cut a carving on one end of a pipe and having screwed on it close. The clamp can be rearranged or dismantled at any time.

You can buy threaded pipes in any hardware store. You can buy not only ordinary pipes, but also elements with a galvanic covering. The movable clamp sponge will slide best on black pipes, which are also quite cheap. The advantage of galvanically coated pipes is, that they are protected against corrosion. exept this, in contact with glue, unlike simple pipes, elements with such a coating do not leave dark spots on the workpiece.

To protect the protruding thread, you can use special removable caps. That long clamps at contraction do not bend, it is recommended to use harder elements with a diameter? in.

If when gluing a large structure and at hand there is no clamp of the required length, you can use two short devices. To do this, you will need to connect them with a coupling.

G-shaped clamps

This type of clamp is used for most work, therefore it is recommended to buy them as much as possible. They come in different sizes, but the most commonly used devices with a width of capture in 100 and 150 mm.

G-clamps must be of good quality, since the brackets of cheap clamps bend and work with them is quite difficult. However, there are quite cheap lightweight clamps of excellent quality on sale.

There are specialized G-shaped clamps with increased grip depth. With their help, you can reach out of reach of ordinary clamps. Edge clamps are available to fix the pads, able to press the workpiece in two directions.

Devices are also divided according to the type of manufacturing material:

- Forged steel clamps allow a large compression force. Therefore, they can be used even during welding to fix steel beams.

- Cast iron clamps are less durable, as from excessive effort brittle cast iron can burst.

When choosing a G-shaped clamp you need to make sure, that their screws are large, the surface is flat, and the collar is thick and has a rounded end.

Joiner's clamps should be serviced in the same way, like another tool. Persevere, rods and jaws of devices should be cleaned immediately after gluing. The dried glue is difficult to remove and leaves cracks on the wooden parts. That the screws of clamps rotated smoothly, it is recommended to lubricate them with wax. It is better not to use oil and silicone lubricants, because they can contaminate the product.

There is almost another "one-handed" master, clamps are able to help, if any part needs to be fixed for processing, "Hold", and both hands are busy. It is difficult to do without them when assembling homemade furniture or gluing any wooden parts, which need to be tightly pressed together and connected. Therefore, for carpentry and other work, it is recommended to have carpentry clamps of different sizes and types, not forgetting to properly care for them.