Step drill for metal (conical drill): parameters, sharpening

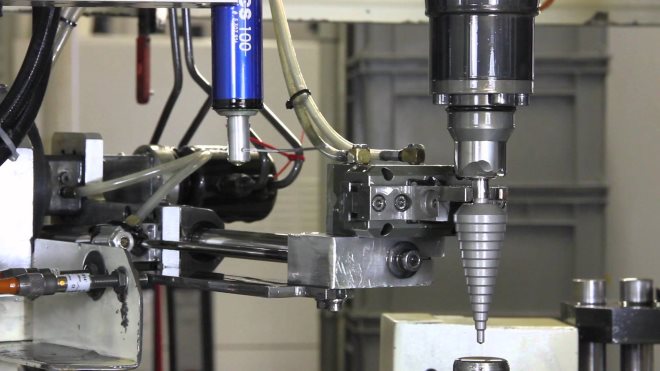

Working part of a step drill on metal (it is also called a conical drill) formed by a spiral groove and a number of stepped annular transitions of different diameters. Thanks to such unique design step drills allow to define at any moment of processing, what diameter the hole is formed.

Одне ступеневе свердло може замінити набір для обробки металу, including crowns

At first glance it may seem, that the use of such drills (which, by the way, are quite expensive) does not make much sense, because you can always choose a tool of a certain diameter and create the necessary hole with it. Meanwhile, conical tools for drilling holes have a number of unique advantages, which make their use justified in many cases.

Scope and design features

Conical (or stepped) drills have a long service life, provided by the high strength of their cutting edges. Unlike a conventional drill, конусне дозволяє виконувати технологічні операції, to implement which in any other situation would require the use of several tools. It is the versatility that largely explains the high cost of drills in this category.

The conical tool for drilling thanks to features of the design allows to carry out processing at high speed, at which the quality of the edge of the holes, which are formed even in sheet material, does not decrease.

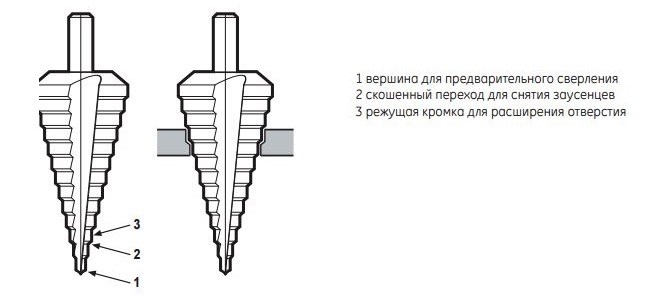

Step drill device

Conical drills can be used to make holes not only in metal, but also in drywall, trees, plastic, etc.. They successfully cope with dense metal, which cannot be said of a drilling tool of any other type.

The sharp tip of the step drill not only eliminates the need for centering tools, but also easy to crash into the structure of even the densest metal. Hole, obtained in this case, does not require additional processing using a file and a grinder.

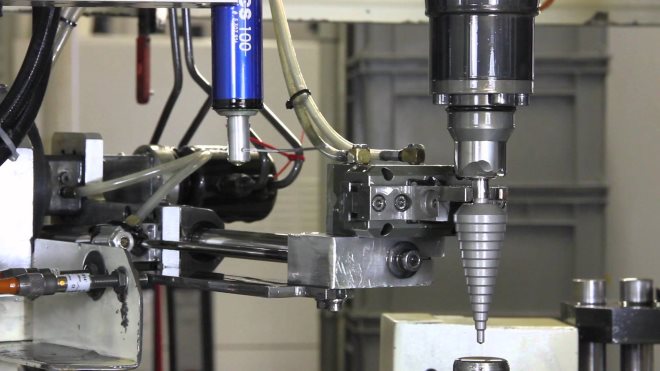

Most step drills are capable of drilling metal up to 4 mm

Translational channels of a step drill, arranged in a spiral, made in different sizes with a smooth transition. This design feature increases the efficiency of the conical drill when working with sheet metal at least on 50%. in addition, during drilling of metal details by the tool with such spiral translational grooves smoothness of its course is provided.

Conical drills can be used as a set with a hand drill, and when installed on special equipment.

Abrasive spraying can be applied to the working surface of stepped drills, which is based on diamond or titanium crumb (this does not contradict the requirements of GOST). This coating of the cutting surface significantly increases the degree of its strength, which minimizes the frequency of its sharpening. Naturally, this advantage of using a cone drill with spraying can be expected in that case, if the rules of its operation are observed and the admissible load on it is not exceeded.

These drills are made of high quality high-speed steel with titanium coating

One of the tasks, which is solved using a conical drill, there is a correction of defects of openings, obtained by another type of tool. To such defects, in particular, include torn edges. Step drills are almost indispensable in those cases, when it is necessary to obtain high-quality holes in sheet metal, products from fiberglass and other polymeric materials.

Given all the above, it is possible to draw a conclusion about that, that taper drills are even more versatile, than a traditional spiral-type instrument. That is why they will not be superfluous on the production site and in the home workshop. About that, how convenient and efficient the conical tool is, the cost of which depends on the diameter of the working part, and from the type of spraying, can be judged by the video processing with its use and the reviews of experts.

What to look for when choosing a conical drill

Choose such a tool, as a drill conical on metal, should only be after that, how will you get acquainted with its characteristics. Its color can tell a lot about a step drill.

- The gray-steel color of the material indicates that, that the drill was not subjected to any heat treatment, in accordance, do not count on its high quality.

- Conical tool, the surface of which is black, was treated with hot steam, which increased its strength.

- The golden color of the steel indicates this, that all internal stresses in the metal have been previously eliminated, which improved its quality characteristics.

- If the surface of the step drill has a bright golden hue, it is characterized by high wear resistance. This provides titanium nitride, contained in the metal. The rather high cost of such products is fully compensated by the long service life.

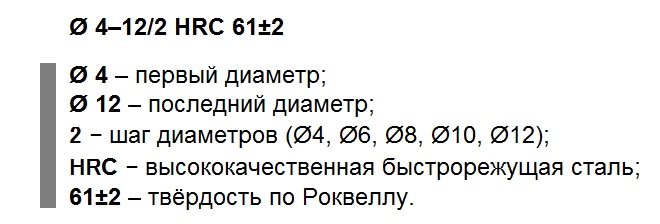

Marking of a step drill speaks about its characteristics

Different types of steel are used for the production of conical drills, which are determined by labeling. If the abbreviation HSS is present in the label, this means, that with the help of this product you can perform high-speed processing, without worrying about it, that it deforms or loses its characteristics under intense heating.

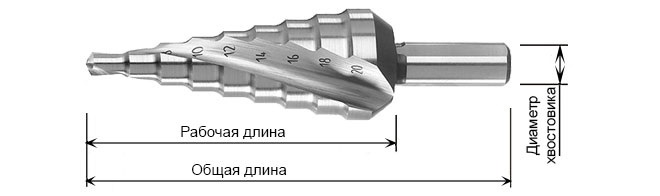

При виборі ступеневого свердла зверніть увагу на основні розміри

Choosing taper drills, the following parameters must also be considered:

- diameter, which cavity depends on the characteristics of the holes, which need to be obtained;

- trademark (this parameter largely determines not only the quality of the product, but also its cost);

- compliance of the purchased conical drill and material, of which it is made, all the requirements of GOST;

- possibility of multiple imprisonment (here it is necessary to be guided only by own preferences and existence of experience in sharpening of spiral and conic drills according to requirements of GOST).

Самостійна заточка

Drills, which are called stepped or conical, allow you to create holes with a diameter of 4 to 32 mm and are available in two versions: with the possibility of sharpening or with the design, which does not involve this technological operation. High cost of products, belonging to the second type, justified by their durability.

Rіzhucha edge they have (subject to compliance with all operating rules) DO NOT blunt for a long time. It should be borne in mind, that sharpening them without proper experience can only lead to that, that they will become unusable.

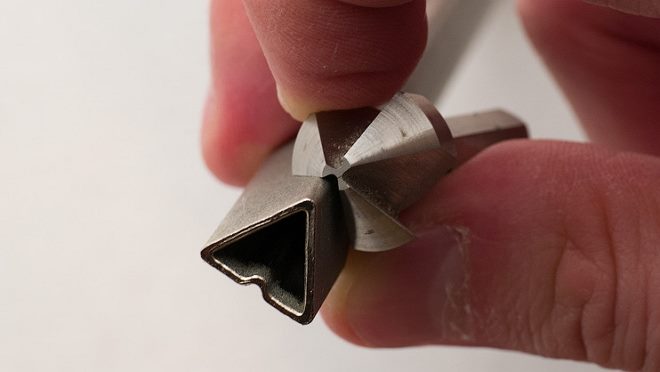

Conical drills of a certain configuration can be sharpened with a triangular abrasive rod

To properly sharpen a step drill, just watch the training video and follow the recommendations of qualified professionals. To perform this procedure, you can not even focus on the drawings, and simply restore the original geometric parameters of the product.

Also in some cases it is permissible to use thin abrasive diamond bars for these purposes, designed for sharpening knives, scissors and other tools

Sharpen such a tool, as well as twist drills with a conical shank, it is possible by means of the special machine, equipped with an abrasive wheel, the working surface of which can be covered with ordinary sandpaper.

Geometric parameters of step drills, guide grooves which have a rectilinear shape, can be restored manually, and products with spiral grooves are best processed with a sharpening machine. It should be borne in mind, the easiest way to restore the geometric parameters of high-quality step drills.

The cost of step drills and recommendations for their selection

If with the purchase of conventional twist drills, the landing part of which is made in the form of a Morse taper, no problems, then the choice of drilling tool of step type has some features. Its cost is affected by two main parameters: working diameter and material of manufacture.

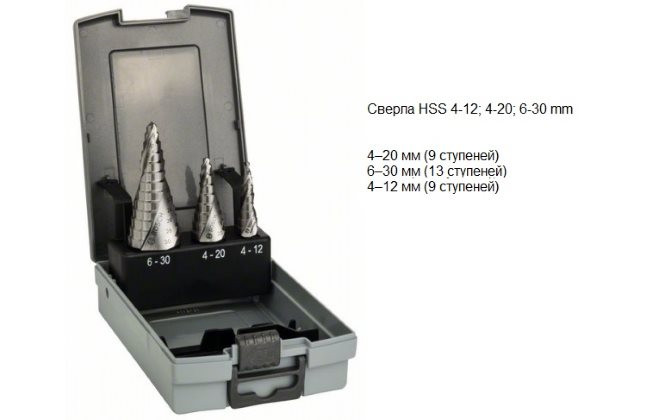

Consumer, who is going to buy a step drill, can mislead a serious price run. To clarify this issue, you can consider several examples of prices. So, relatively low cost (400-500 rubles) different products for forming holes in diameter 4-20 mm. Almost twice (1100 rubles) a step drill from domestic manufacturers will cost the consumer more, which allows you to make holes in diameter 4-30 mm.

Significantly increases the cost of products belonging to a well-known brand. So, the price of step drills from the Bosch company, whose diameter is in the range 4-20 mm, is 1160 UAH, and for the tool, which allows you to get holes in diameter 6-39 mm, must be given to 2000 UAH.

This set of three drills Bosch Swiss production costs 8-10 thousand rubles

Many organizations, engaged in the sale of step drills, offer them at a fairly high price, that without confirming their qualitative characteristics. Buying a tool in such organizations, as there, where it is sold at low prices, the consumer must be prepared for that, that the quality of the drill will be in great doubt. That is why it is necessary to buy conical drills only from those companies, who are ready to provide all the necessary certificates. You should also pay attention to the marking of the drill, by which you can determine, that in front of you are certified products with characteristics, relevant requirements of GOST.

Everyone, who is going to buy cone drills, should be borne in mind, що його досить дорога вартість обумовлена тим, that it is of exceptionally high quality, universality of use, reliability and durability.