Stainless steel drill bits: how to drill stainless steel at home

The question is, how to drill any stainless steel at home, usually, does not occur, if special drills for stainless steels are used for these purposes. Along with such drills, which allow you to quickly and efficiently form a hole of the required diameter, it is necessary to use special cooling structures, as well as strictly maintain technological parameters.

Industrial machines for coolant drilling use industrial machines with coolant supply. In the home workshop you have to learn some clever tricks

Lubricants

Drilling holes in stainless steel products, performed with an ordinary drill, may end in failure. This is due to the fact, that became, belonging to the category of stainless steel, are characterized by high viscosity, so their drilling, especially performed at home, accompanied by significant heating of the cutting tool and, Consequently, its failure.

To drill stainless steel efficiently and quickly, taking into account the above, it is necessary to use cooling material, which, in addition, should have good lubricating properties.

The most common composition, used as a coolant and lubricating fluid during drilling holes in stainless steel, there is a solution, consisting of engine oil and sulfur. For the preparation of such a solution can be used as colloidal sulfur, and sulfur for smoking, which is often called "sulfur color".

In that case, if sulfur, available to you, there is a fine powder, it can be immediately mixed with machine oil without special preparation. If you bought lump sulfur, it must first be ground.

You can make drilling stainless steel products more efficient, if you use a lubricating-cooling mixture to perform such an operation, consisting of sulfur and fatty acids, which can be obtained independently at home. To do this, do the following:

- grind a piece of laundry soap (can be used the cheapest);

- mix chopped soap with hot water and mix thoroughly;

- to the resulting solution add technical hydrochloric acid;

- wait, until fatty acids begin to rise to the surface of the resulting solution;

- then add plenty of cold water;

- remove the hardened trunk of fatty acids from the surface of the solution, which are subsequently used for the preparation of lubricating and cooling solution.

Obtained in the preparation of liquid for drilling fatty acids are mixed with sulfur in the ratio 6: 1. Using the solution, made according to this recipe, you can easily drill a stainless steel product, which differs even in considerable thickness. Naturally, that when performing such a procedure, certain technological recommendations should be followed.

Useful techniques during drilling

There are some simple tricks, allowing to qualitatively and quickly drill a hole in stainless steel. List the most common of them.

- It is better to drill stainless steel horizontal surfaces, pre-passing the drill through the lubricating and coolant, poured into a rubber washer or plastic stopper, installed directly above the location of the future hole.

- If it is necessary to drill a hole in a stainless steel surface, located vertically, then in the place of drilling you can fix the ball, made of paraffin, which will provide lubrication of the cutting tool.

- Regardless, you will drill stainless steel with a household electric drill or industrial equipment, it is better to carry out such technological operation on small turns of the cutting tool (100-600 about / min). Use of even very high-quality liquid for greasing and cooling will not be able to provide high-quality result of drilling of stainless steel., carried out at high speeds.

Long chips are an indicator of the correct selection of stainless steel drilling speed

To get a better idea of that, how to properly drill stainless steel parts, you can study this process on video.

There are no problems with drilling at low speeds, if a machine or drill is used for this purpose, on which the option of adjustment of this parameter is provided. If there is no such option, then stainless steel can be drilled as follows.

- The electric drilling tool runs literally on 1-2 seconds.

- After a short start, the drill switches off immediately.

This simple technological technique allows to ensure low speed of rotation of the cutting tool, what, actually, and is required for high-quality drilling of stainless steel.

drill selection

If you need to drill a stainless steel product, the choice of drill along with the selection of appropriate lubricants and coolants, as well as the technology of the operation is the most important procedure, which determines the quality of the end result. Until recently, cobalt drills were used to drill stainless steels.

Cobalt drill for drilling stainless steel, cast iron and heat-resistant steels without prior centering

Cobalt drills, which were equipped with cylindrical shanks, were produced from alloys brand P6M5K5, and in some cases of P18 steel, in which the amount of cobalt was limited 5%. Advantages of drills, made of alloy, containing cobalt in its chemical composition, are, that this chemical element gives the tool high hardness, which allows it to easily drill any stainless steel product. Regulatory document, according to which such instruments were produced, was GOST 10902-77.

To date, these drills are no longer produced by industry, and finding them on the market is not easy. Meanwhile, modern manufacturers produce many analogues for working with stainless steel, whose quality is at a high level. If you choose from such tools, you can pay attention to drills of foreign production, on which the HSS-Co marking stands. They are available according to DIN standard 338 and made of steel, which contains at least 5% cobalt. Essentially, material, from which they are made, is an analogue of alloys of grades P18 and P6M5K5.

A characteristic difference of the drill with the addition of cobalt is a blunt angle of sharpening to facilitate centering at the beginning of drilling

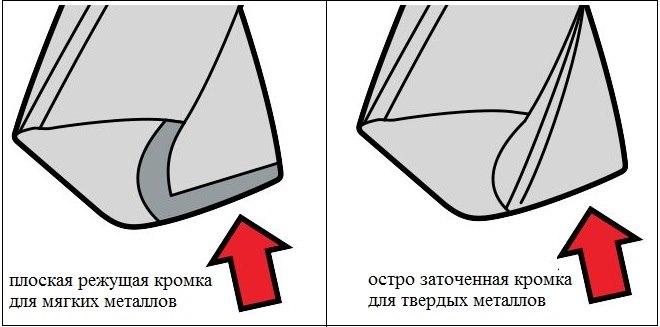

It is not necessary to use a cobalt tool for this, to drill stainless steel at home. Drills also cope well with this task, made of hard alloys. Such drills for stainless steel differ not only in the material of their manufacture, but also very sharp sharpening of the cutting part (sharpening is performed on one side). Trace, however, consider, They are quite expensive and buy them in regular hardware stores is not always realistic.

Sharpening the drill edge is different for soft and hard metals

If you need to drill a hole in stainless steel, use a few tips, which will allow you to perform this procedure without much difficulty.

- If the thickness of the stainless steel product, which must be drilled, exceeds 6 mm, then it is best to perform this procedure by the double method. The essence of this method is, that in stainless steel a hole of small diameter is first drilled, and only after that it is reamed to the required size.

- In that case, if the thickness of the product is small (1-2 mm), it is possible to drill a hole in it by means of a usual drill on metal, the cutting part of which is sharpened at an angle 120 °. It is very important to perform the operation at low speeds (to 100 about / min), then the tool will not overheat and will not fail.

- If the hole needs to be drilled in a stainless steel product, whose thickness is less 1 mm, it is better to use drills of a step design. The use of such a tool, which can be purchased at many hardware stores, allows to receive qualitative apertures even in very thin details.

If you are going to drill a hole in stainless steel, but never done before, should not be limited to theoretical information. It is also advisable to watch videos on this topic, which is easy to find on the internet. in addition, undertaking to solve such a difficult task, it is desirable to stock up on quality cutting tools and appropriate equipment.