Melting point of brass and melting at home

Such a parameter, as the melting point of brass, is important in many situations. This is due to the fact, that this metal, which is based on copper, very actively used for the production of various purposes. Knowing the melting point of this metal, It is possible to make not only interior items from it even at home, but also elements of different designs.

The maximum possible grinding of metal is one of the main conditions for melting brass at home

Characteristics and applications of brass

Among the many varieties of brass, the most common are two types - double and multicomponent. The main element, which determines the characteristics of this alloy, there is zinc, which may be present in it in an amount of 5 to 45%. In addition to zinc, in the composition of brass, depending on its brand may be present manganese, iron, nickel and lead, which also affect its properties.

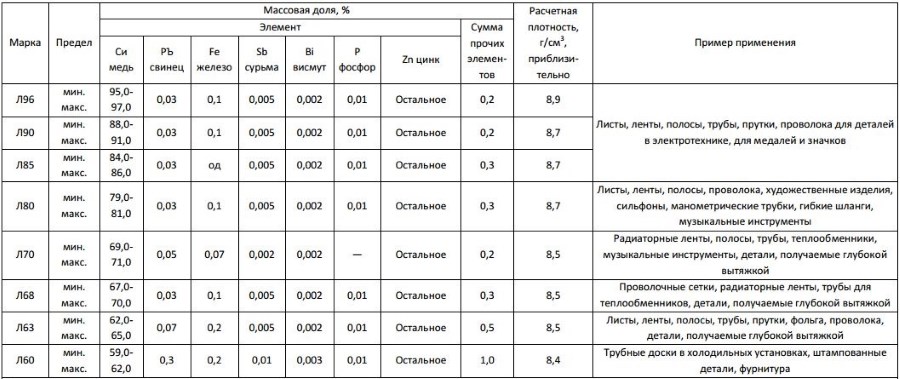

Simple brass - chemical composition and application (click to enlarge)

Brass, as well as other copper alloy - bronze, is actively used in various industries. in addition, Brass is used to make furniture and interior items. The main technological operation, that allows to give to a product from brass a necessary configuration, there is casting, which, as mentioned above, can be performed at home. Naturally, to perform such an operation, you need to know, at what temperature the brass melts.

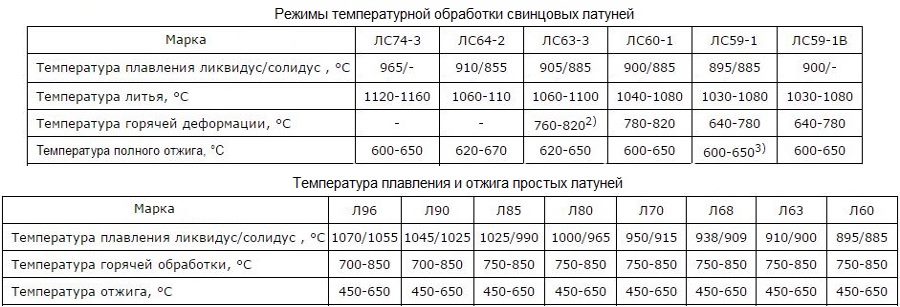

Modes of processing of simple and lead brass (click to enlarge)

Depending on the chemical composition of brass, its melting point may be in the range 880-950 °. The main element, which affects this parameter, there is zinc: the more it is in the composition of brass, thus at a lower temperature it can be melted.

Melting is not the only technological operation, which is well exposed to brass. Like bronze, this alloy can be subjected to various types of machining. Moreover, welding can be used to connect brass parts. On the fluidity of brass in the molten state, which is especially important to consider when performing casting, negatively affect such chemical elements in its composition, like lead and bismuth.

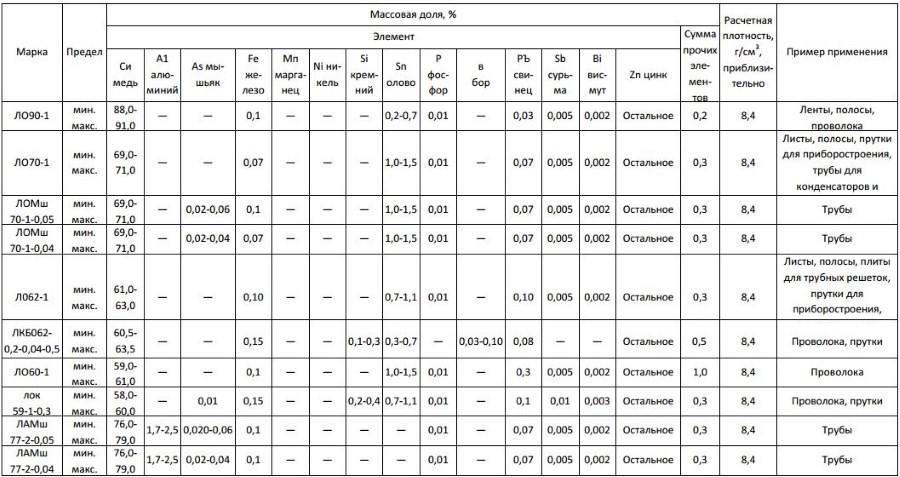

Complex alloy brass - chemical composition and application (click to enlarge)

Brass, as well as bronze, which also belongs to the category of alloys, made on the basis of copper, - non-ferrous metal, which largely determines the scope of its application. Brass products, having a yellow-golden color, differ in high decorative characteristics, but so that later they do not turn black from the interaction with the surrounding air, they must be covered with protective compounds.

Like bronze, brass has high corrosion resistance, which allows you to successfully use this alloy for the production of items, which are operated in conditions of high humidity. The widespread use of brass products in various industries also contributes to that, that it has good antifriction properties.

One of the advantages of this alloy, which is especially important when performing casting, has a low propensity to liquation.

Having mastered the technique of casting brass, you can create real masterpieces

Alloy products, made on the basis of copper, which includes brass, widely used not only in industry, but also in everyday life. In this regard, information about it, how to melt such metal, what is its melting point and how to properly perform casting, can be useful in many situations.

What you need for casting

Knowing that, how to melt brass, it is possible not only to carry out repair of brass products, but also to make them at home. To practice casting brass or bronze, appropriate equipment should be prepared, part of which can be made with your own hands. in addition, should be considered, that not all brands of brass and bronze have good fluidity, which greatly complicates their casting.

To melt brass or bronze, which have a fairly high melting point, a special oven will be required. Many home builders make such stoves themselves, operating on the induction principle. As the basis of such a heating device, you can use refractory bricks. The elements of the brick frame are connected with a special solution, able to withstand high temperatures.

Homemade melting furnace with reinforced metal frame

Capacity, in which the melting itself will be performed (cup), can also be made ??at home. Graphite or fireclay brick will be suitable as a material for it. The best material for making a crucible, according to many experts, there is fireclay brick. This material is durable and allows you to perform a much larger number of swimming trunks, than a vessel made of graphite.

Crucible made of refractory clay, coated with liquid glass with talc

The most important element of the furnace, in which brass or bronze can be melted, there is a heating element. Of course, you can heat the crucible with coal, but furnaces are more efficient and easy to use, heating in which is carried out using the induction principle. To make and effectively use a heating device of this type, you will need a power source, whose power is about 20-25 kw.

Melting brass requires the use of such a substance, like a storm, which is added to the alloy to improve its characteristics. Given that fact, that you have to work with metal, which has a very high temperature, all security measures must be provided. One such event, which minimizes the risk of fire of various objects, located in close proximity to the melting furnace, is the use of asbestos sheet, which you want to cover the floor.

For the manufacture of heating elements of the furnace will need a thick nichrome wire and ceramic tubes

To remove the crucible from molten brass requires special tongs with long handles, and all the work, associated with exposure to high temperatures, should be performed in tight gloves and goggles. Because when melting brass begins to emit zinc, vapors which are harmful to health, good ventilation must be provided at the casting site.

Not only smelting can be done at home, but also welding (soldering) brass. To perform this technological operation, with which you can bring back to life broken products from these alloys, you will need a gas burner and a special solder, which is based on technical silver. Such solder, as well as flux, specially designed for soldering non-ferrous metals, you can buy ready-made or make it yourself, using technical silver and copper.

Once all the equipment and necessary tools are prepared, you can start directly casting brass.

melting process

In order for brass to turn into a liquid state faster, it is better to put it in a crucible in a crushed form. It should be borne in mind: the smaller such pieces, placed in a crucible, the sooner the melting process begins.

After you fill the crucible with crushed metal, it is necessary to install the vessel in the furnace and start heating it to the melting point of brass. If you use a factory muffle furnace for melting brass, then monitor the processes, flowing in the crucible, it is possible through a special window. In that case, if you made your own stove of the simplest design, you will need a lid made of refractory material, which will close the tank for melting brass.

Melting in a compact oven of factory production can be made directly in the kitchen

The crucible is removed from the oven only then, when all the metal, which is placed in it, completely melted. To remove the container from the brass should use special pliers and do it as carefully as possible. On the surface of brass, subjected to melting, always present film, which must be removed. It is not difficult to perform such an operation, if to take for this purpose a usual steel wire.

You must prepare a mold for casting brass products, thanks to which the metal, passing from a liquid molten state to a solid, will take the necessary shape. Pouring brass into this form is performed only after that, as removed film, which was mentioned above. Then you just have to wait, when brass, flooded into shape, completely solidify and cool.

Filling molds with brass melt

At home, you can use a simplified version of the melting furnace, using a gas burner as heating elements. It is possible to subject brass to melting in this way, securely fixing the gas burner under the melting vessel in a vertical position. It is important to monitor this, to the flames, which gives the burner, evenly covered the entire lower part of the vessel.

The melting process will go faster, if you use a second burner

Using such a simple device, should be borne in mind, that brass, which will melt in the crucible, subjected to significant oxidation. To minimize the consequences of this process, which negatively affects the characteristics of the alloy, you can use ordinary charcoal.

So, there are several ways, that allow you to effectively melt brass at home. Choosing one of them depending on your preferences and financial capabilities, you will be able to make products for various purposes from brass by casting.