Pipe thread. Types of pipe carving. Methods of knurling and measuring the thread pitch

One of the simplest, but sufficiently reliable methods of connecting water and gas pipes are threaded connections. Pipe thread, necessary in this case, is obtained by creating a spiral recess (channel). Cutting of turns is possible both on external, and on the inner surface of the product. Kneading must meet all the presented standards, otherwise the quality of the connection cannot be guaranteed.

There are different types of pipe threads, each of which has its own characteristics

What can be a pipe thread?

Regulatory documents allow the use of such varieties:

- Cylindrical. To obtain it requires a spiral cut with a profile, formed by an isosceles triangle, with an angle at the apex equal to 55 degrees.

- Conical. Spiral cutting is performed, identical to the previous one, but with a taper on the beveled section of the pipe, equal to 1 to 16.

- Inch. The angle at the vertex of an isosceles triangle in this case will be equal to 55 degrees. In the United States, and in Canada, inch cylindrical threaded profiles are used, the angle at the apex of which is 60 degrees. Their international name is NPSM, they are produced in a range of sizes from 1/16 inches and up 24 inches.

The popularity of the latter option, inch pipe thread, has been coming to naught lately. Cylindrical or conical cutting is much more often used in new pipelines.

Cylindrical type has its own designation - the letter "G", the presence of a conical cut of the pipe indicates the marking with the letter "R" or "K" (for conical inch cuts). The parameters of the metric cylindrical knurling are highlighted in the Guest number 8724-81. For metric conical cutting there is GOST-25229-82, if the thread is conical inches, then GOST is used 6357-81.

The conical thread gives a stronger connection, therefore pipes with such cutting are used in the industry and conditions, which requires increased reliability

Conical thread is used for household purposes less often, basically this type of thread has become widespread in the assembly of hydraulic devices, construction of oil and fuel pipelines for cars and aircraft. The conical type of cutting has a stronger connection, close to the monolith. Conical knurls, designed to work under high pressure, are made according to the American NPT standard.

The main parameters of threaded connections, in addition to the above varieties, there are such factors:

- Direction, Location.

- The unit of measurement of the profile is inch or metric (in mm).

- Step - repetitive distance between turns.

- Internal diameter of slicing.

There is also such a concept, as non-standard threads. They happen, example, rectangular or square. Production of this type of cutting is possible only on condition of providing by the customer of detailed drawings with the indication of all individual parameters of a carving..

What is the difference between metric thread and pipe?

The main difference between the two types of cutting is the shape of the threaded ridge and depressions. The metric profile is based on an equilateral triangle, therefore, all the angular dimensions of this type of cutting are equal and make up 60 degrees, while the inch pipe has angular dimensions 55 degrees. All metric thread parameters are bound to the millimeter, while the dimensions of the pipe thread are calculated in inches. Another nuance - the size of the pipe thread takes into account the wall thickness of the product, which are different depending on the operating pressure, on which these or those pipes are calculated.

The parameters of the metric thread are presented in millimeters, and inches - in inches

Products with metric type of slicing must be marked with the letter "M". The dimensions of the metric profile are in the range from 1 mm to 600 mm. Threaded metric pitch can range from 0,075 mm to 3,5 mm. Products with the smallest metric thread pitch are used for fine work (measuring instrument), with a medium step - to create parts and assemblies, operating in conditions of constant vibration. The largest metric threads are involved in the construction of heavy load-bearing structures.

It is interesting! In tubes with an inch knurled pitch is calculated in the form of the ratio of the number of turns per inch of length of the knurled thread.

Inch thread, however, occurs in industry and everyday life more often, than metric. Pipe thread is measured almost everywhere in inches - a more universal unit of measurement for the water and gas industry.

Since different types of knurling have different angles at the vertices, combine two types of thread, even have identical dimensions, impossible. To make the transition from metric thread to pipe requires special shaped elements - adapters.

Features of a round carving

This type of slicing can be found on sanitary fittings (regulated by the state standard number 13536-68) and on lighting fixtures, as well as on the bases and cartridges for them. This variety makes it possible to obtain compounds, periodically subject to review. The profile for round threaded connections is obtained by connecting two arcs with the same radius. Thread pitch is always measured in millimeters, and the letters "Kr" are used as a designation.

Details, which are used for household purposes, are equipped with a usual round carving

Design features of round knurling provide it with long service life and considerable resistance to loading. The profile is not erased even with frequent use. Also, such a thread can be used quite successfully in systems, working in a polluted environment. Round type threaded connections are used, example, when coupling railway cars.

Determining the size and type of thread

The parameters of the existing slicing can be determined in the following ways:

1. Use of calibers. Special gauges allow you to determine the pitch and diameter of the outer, and internal knurling. To measure the internal thread requires a cylindrical caliber with applied external thread, Screwing into the pipe. Properly selected caliber will be screwed into the pipe easily, if there is a discrepancy of even one turn, it will not be possible to place the caliber inside the pipe.

The size of the external thread pitch is determined in a similar way: for this purpose the caliber with a carving on the inside is taken and screwed on a pipe.

The disadvantage of this method is obvious: it may take a long time to select the right caliber, the number of which in the complete set reaches 120.

Wrinkle! A fitting or coupling can be used as a caliber, the slicing parameters of which are known.

The type and size of the thread can be determined using the caliber, screw into the pipe

2. Using flat templates (thread gauge). An easier and faster way to determine the size, truth, does not always provide an accurate result, therefore, it is almost never used in professional conditions. The plate with the applied profile of cutting is applied to a pipe carving (outside or inside the product). Between the threaded combs and the template, chosen correctly, there should be no gaps.

Calipers and micrometers are also used to measure the threaded pitch, but they are only suitable for internal slicing. Calibers and thread gauges are more versatile devices.

What tools are used for knurling?

The process of knurling cutting on the pipes can be done in a number of ways:

- Factory knurling method. Threaded pipe goes on sale ready-made.

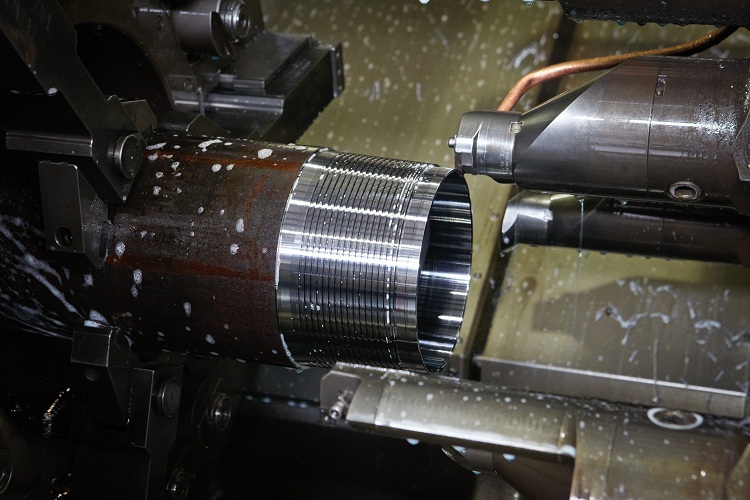

- Mechanical cutting. This method requires special equipment, many workshops use lathes for this purpose. The pipe is clamped in the machine cartridge, the cutter for knurling of a carving is placed in a support. The chamfer is removed inside and outside the pipe. The grooves are cut when moving the caliper, the speed of which must be adjusted for more accurate knurling. In general, this method provides the thinnest possible slicing.

- Manual knurling method. In some cases, when the pipe cannot be placed in the machine (example, if it is necessary to cut a thread on an already installed pipeline), hand tools are used. To cut by hand you need a tap or a special die.

The tap is used when knurling the internal thread. The tap shank is inserted into the holder, then the tool is slowly screwed into the cavity of the pipe. This method requires sufficient physical effort.

To cut with a die, it is necessary to fix the tool in a clip from one, and better - two handles. The die is screwed on a section of pipe clockwise. When working with pipes with a diameter of more? "Two tools are used at once: clean and rough die.

These types of pipe cutting do not require a high level of skill, treatment of pipes with a die or tap - a fairly ordinary procedure, carried out by all plumbers when working with metal pipes. These methods are relevant when processing as plumbing, and gas and heating pipes.