Knitting wire for reinforcement: costs of 1 t and on 1 m3 of concrete

The so-called knitting wire is used for this purpose, to create a single frame from individual reinforcement elements, which is used to strengthen reinforced concrete structures. Essentially, such a product, which is used for binding of elements of reinforcing structures and is made according to requirements of GOST 3282-74, is one of the types of metal.

Fastening of the reinforcing frame of the foundation with a knitting wire

The expediency of using steel wire to bind reinforcement

Wire of different diameters, which is carried out in accordance with the requirements of GOST 3282-74, has a general purpose. The material for its manufacture is low-carbon steel. Depending on the purpose of the wire can be further subjected to heat treatment, cover its surface with a protective layer of zinc, to make with normal or increased accuracy. Nails are made of general purpose wire, different types of fences. It is also used for binding.

The name of the knitting wire is due to that, that it is most often used to fix several elements of different structures by strapping. For this purpose, this product is most often used in construction - to create reinforcing frames. The wire for tying the reinforcement must be soft enough, therefore it is additionally subjected to annealing, so that it bends better and breaks less when bent.

Heat-treated zinc-coated knitting wire (PRO-1C)

Soft annealed wire makes it much easier to make a website, which will securely fix the fittings in any spatial position. It is for reasons of ease of bending that products are used to tie reinforcement, whose diameter is in the range of 1.2-1.6 mm. This wire is easy to knit due to its small diameter, allowing to carry out various knots on a reinforcing framework.

Diameter interval, which is mentioned above, is optimal, since thinner wire is often torn, and thicker is harder to work with: it does not make it possible to make a strong knot and, in accordance, ensure high reliability of binding. The choice of knitting wire with or without zinc coating depends only on it, how durable the combination of reinforcing frame elements for a concrete structure should be.

Fastening of rods by means of guns for binding of armature

An alternative to connecting fittings with knitting wire is welding, with which you can mount metal parts much faster. Meanwhile, high-quality and reliable reinforcing bar connections can only be obtained by contact welding, which requires a special apparatus and the experience of a qualified specialist.

If you use for these purposes, conventional electric arc welding, then the joint may overheat, as a result, the reinforcement will become more fragile and may break under the influence of significant loads. Concrete structures, the reinforcing frame of which is connected by electric arc welding, do not differ in high reliability, as they are unable to withstand prolonged and peak loads.

If the conditions of installation of a reinforcing framework use of welding is not provided, it is fixed to each other by a knitting wire. That is also important, that high-quality knitting does not require high skills, and you can learn the correctness of this procedure very quickly. Quality control of this work is also quite simple, for its implementation it is enough to check, whether all parts of the reinforcing frame are strapped.

The main parameters of the product

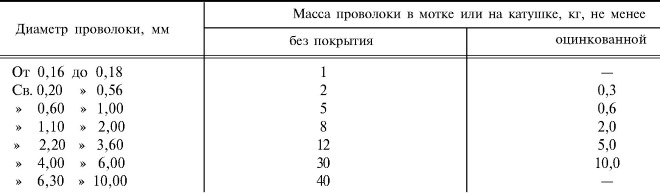

Wire, used for binding concrete reinforcement, can be delivered to the customer in skeins or wound on coils. The weight of such a skein or coil is determined by the requirements of the regulatory document. So, specified in the standard, that the minimum weight of the skein or spool, in which the wire with a diameter of 1,1–2 mm is delivered, should be:

- 2 kg (in the presence of a zinc coating on the product);

- 8 kg (without zinc coating).

High-quality wire has a normalized stiffness and can withstand more bends

The consumer can order skeins by prior arrangement with the manufacturer, which will weigh 0.5-1.5 tons. Regardless of their weight, only one piece of product can be wound on skeins with knitting wire for fittings.. Unlike skeins, coils may contain up to 3 such segments.

Only the weight is indicated in the shipping documents for the batch of knitting wire for the reinforcement, and the length can only be determined approximately. This parameter is not specified in the standard, and determining the length of the product in a skein or on a spool is further complicated by that, which is even stated in the normative document, that the diameter supplied to the customer wire may differ from the nominal to a lesser extent.

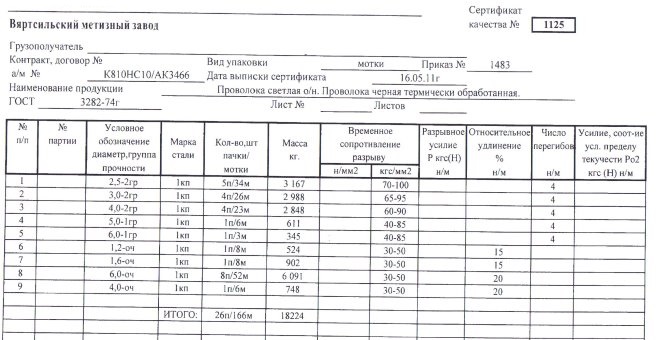

Example of an accompanying consignment note for a batch of knitting wire

Tolerances on the maximum deviations of the diameter of the knitting wire with a cross-sectional size of 1.1-2 mm, depending on the accuracy of manufacture are in the range of 0.05-0.12 mm. To determine, how many meters of product are in the skein, you need to find out first, what specific weight it has (in other words, how much it weighs 1 running meter of wire of a certain diameter). A quick and accurate method of determining this parameter is to distribute the mass of the pre-weighed piece of product by its length. To find out, how many meters of knitting wire for reinforcement is in the skein, it is enough to divide the total weight of the skein by the obtained value.

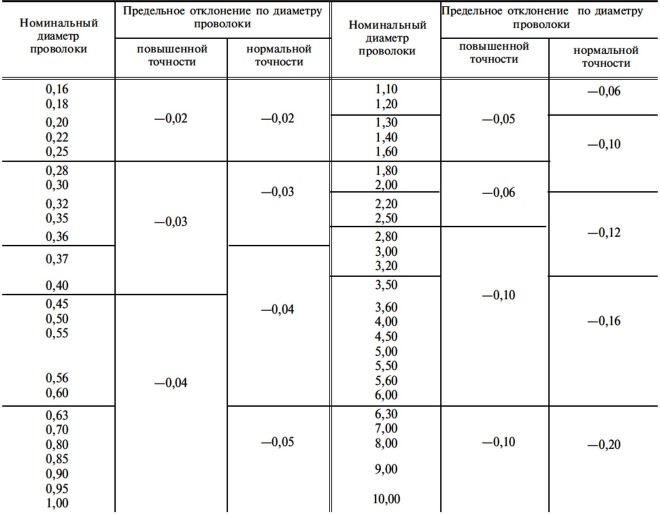

Permissible deviations of wire diameter according to GOST

The second method of determining the total length of the wire in the skein are purely calculated and allows you to calculate fairly approximate parameters. Knowing the nominal diameter of the wire in the skein, which may differ from the actual value of its cross section to the larger side, the weight of one meter of the product is determined by the formula. Taking into account these errors, the estimated weight of one meter of knitting wire for reinforcement will be less than its actual value. This means, that the actual length of the product in the skein will be greater than that, which is obtained when performing calculations.

The error between the actual and estimated values will be even greater, if in a skein of a wire with a zinc covering. In such cases, the increase in error is due to, that the density of zinc, which covered the surface of the wire, Less, than a similar parameter of steel (the density of steel is 7850 kg / m3, while the density of zinc - 7133 kg / m3). To accurately determine the length of galvanized wire in the skein, complex calculations are required taking into account the thickness of the protective layer, which can also vary along the entire length of the product. That is why such calculations will always give values with varying degrees of accuracy.

The minimum weight of a piece of wire on a spool

In practice, to determine the weight of one running meter as covered, so not covered with a protective layer of zinc knitting wire for reinforcement use the same formula M = q x S x h, where:

- M is the weight of one running meter of wire, which is measured in kg;

- q is the density of the metal, of which the wire is made;

- S is the cross-sectional area of the wire, measured in m2;

- h is the length of the product.

The cross-sectional area of the wire, which is a circle of a certain diameter (d), calculated by the formula S = 3.14 x d2 / 4.

As an example, calculate the length of a skein of knitting wire by weight 8 kg, has a diameter 1,1 mm

- Cross-sectional area: S = 3.14 x 0,00112/4 = 0,00000095 m2.

- Weight of one running meter of a product: M = 7850 x 0,00000095 X 1 = 0,00745 kg.

- The length of the wire in the skein: L=8/0,00745 = 1073 m.

How to calculate the cost of wire for tying the reinforcement frame

Calculate the cost of knitting wire, required for strapping, should be in each case. Use norms to solve such a problem, stipulated in regulatory documents, not work, since such norms simply do not exist. The advice of experienced professionals will not help much in this situation, since they are all based on personal experience and can be very different from each other.

The main recommendation is, that amount of wire, which you buy for strapping, must be twice the estimated value. This is due to the fact, that the wire often breaks during tying, so you should definitely have it in stock.

Specialists, as mentioned above, give various recommendations for determining the cost of knitting wire for fittings. Some of them say, what on 1 a ton of rebar will be required 10-15 kg of wire (1-1,5%), others - what will need to be used 15-20 kg.

If we consider the length of the segment, which is required to tie one knot, even here the opinions of experts differ. Some of them claim, that knitting one knot can do without and 10-15 see products, others believe, that such a procedure requires at least 30-50 see knitting wire. These views can be taken into account, but you will have to determine the wire consumption based on your own experience.

Simple calculations allow to determine with high accuracy, how much wire will be needed to perform the binding of a certain reinforcing frame. The following parameters must be taken into account:

- diameter of rods, to be bound;

- the diameter of the knitting wire itself;

- number of nodes, in which it will be necessary to carry out binding.

Wire consumption will double in those nodes, in which two horizontally located reinforcing bars with vertically located intersect. In the middle part of the reinforcing structure units are allowed to perform in a checkerboard pattern - through one joint, while at the edges of the frame all the joints must be tied.

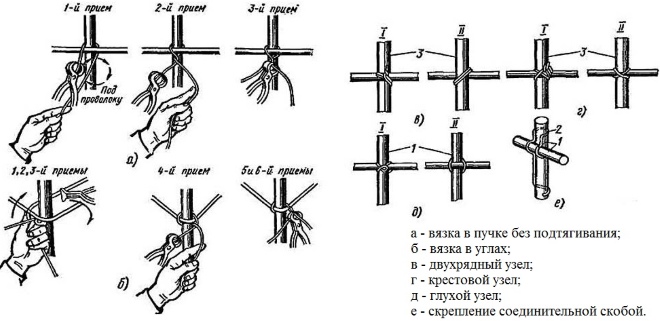

Wire consumption also depends on the knitting pattern

The length of the segment, which you will need to fix one node, determined experimentally, after one test run. You can do differently and determine the length of such a segment by calculation, using the following formula: F=2 x 3,14 x D/2. Parameters, used in this formula, is:

- F - determines the length of the circle of the reinforcement used (coverage).

- D is the diameter of the reinforcing bars.

It should be borne in mind, that when using a wire of smaller diameter it needs more, since the nodes of it will need to perform several turns.

By calculating the length of a piece of knitting wire for reinforcement and multiplying the value obtained by the number of knots in your reinforcement frame, you will learn, how many total meters of product you need. According to the total length of the wire, it will be easy to determine its weight, multiplying the obtained length by the specific gravity of one meter.