Properties of bronze: color, density, specific weight, marking, stamps

It is the properties of bronze that determine the popularity of this well-known material, has not declined for several millennia. As a result of the active development of the metallurgical industry, various brands of this alloy have been developed, each of which differs in its features and areas of application.

Bronze rod in the shape of a circle (cobblestone) serves as a raw material for the production of fasteners, bearings and other engine parts

Types of bronze alloys

About that, how popular bronze was and remains, says that fact, that an entire period in human history has been called the Bronze Age. Scientists believe, that the very word "bronze" owes its origin to the old name of the Italian city of Brindisi, known for its foundries.

Initially, bronze was obtained by melting and mixing such metals, like copper and tin. Bells were often cast from it, so it was called the "bell tower". It was also used to make weapons and tools, various household utensils, sculptural compositions and interior items.

Figurines made of bronze alloys are made by the technology of artistic casting

Many old photos show bronze interiors, which still impress with their beauty. With the development of the metallurgical industry, other types of bronze appeared, in which instead of tin began to introduce aluminum, iron, beryllium, silicon, zinc, lead, phosphorus and others

Changing the traditional chemical composition of bronze has not only improved its mechanical properties (hardness, strength, wear resistance and resistance to aggressive environments), but also change its color. So, the color of the surface of bronze products may change from red (if the bronze contains a large amount of copper) to gray and even black. Changing the color of this alloy by varying its chemical composition is a very important property in the manufacture of decorative products.

The color of rolled bronze depends on the content of chemical elements

Many confuse bronze with brass, although it is a completely different copper alloy with different properties, in the chemical composition of which, in addition to the base metal, there is zinc. Although the color of brass can be confused with some brands of bronze, in many of their characteristics they are different materials, therefore, their areas of application differ.

Another common copper alloy, the main alloying element of which is nickel, - this is cupronickel. The surface of its products has a beautiful silver color. Cupronickel is actively used for minting coins and making cutlery.

Depending on that, contained in bronze tin or not, it can belong to the tin or tin-free type.

If we talk about the first type of bronze, then the maximum amount of tin in their chemical composition can reach 33%. Increasing the tin content slightly reduces the specific gravity and density of the parent metal, but increases such properties of the final material, both hardness and strength. in addition, with an increase in tin in the composition of bronze color products, which are made of it, becomes brighter, which is noticeable even in the photo. In addition to tin, which also reduces the melting point of the finished alloy, the chemical composition of this metal may contain other chemical elements - arsenic, lead, zinc, etc.

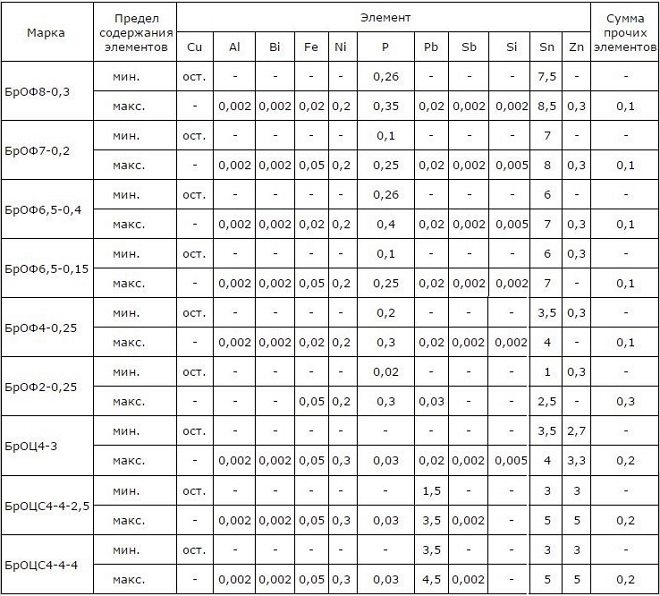

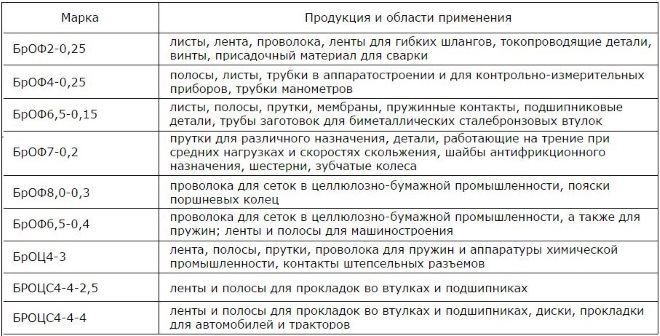

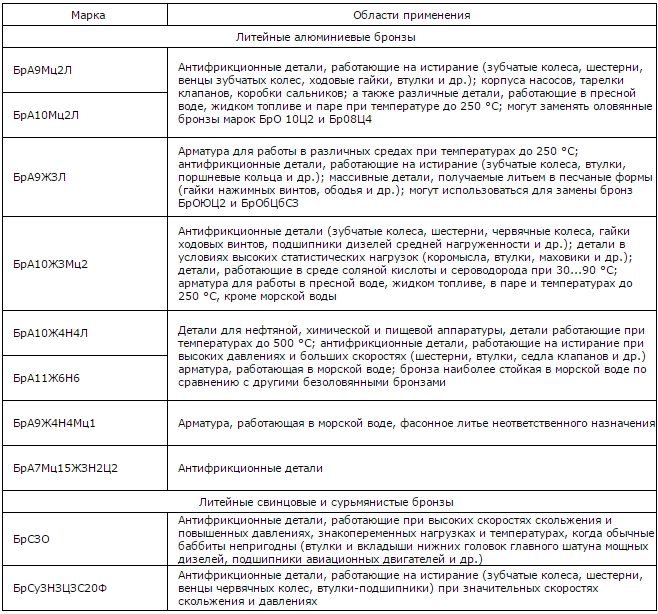

Chemical composition of tin bronzes

If we talk about tin-free bronzes, the specific weight and density of which differ slightly from the similar characteristics of the alloys of the first type, then in many of their mechanical properties they can surpass not only tin bronzes, but also some brands of steel. Naturally, as the colors of the products, made of such alloys, can be very different.

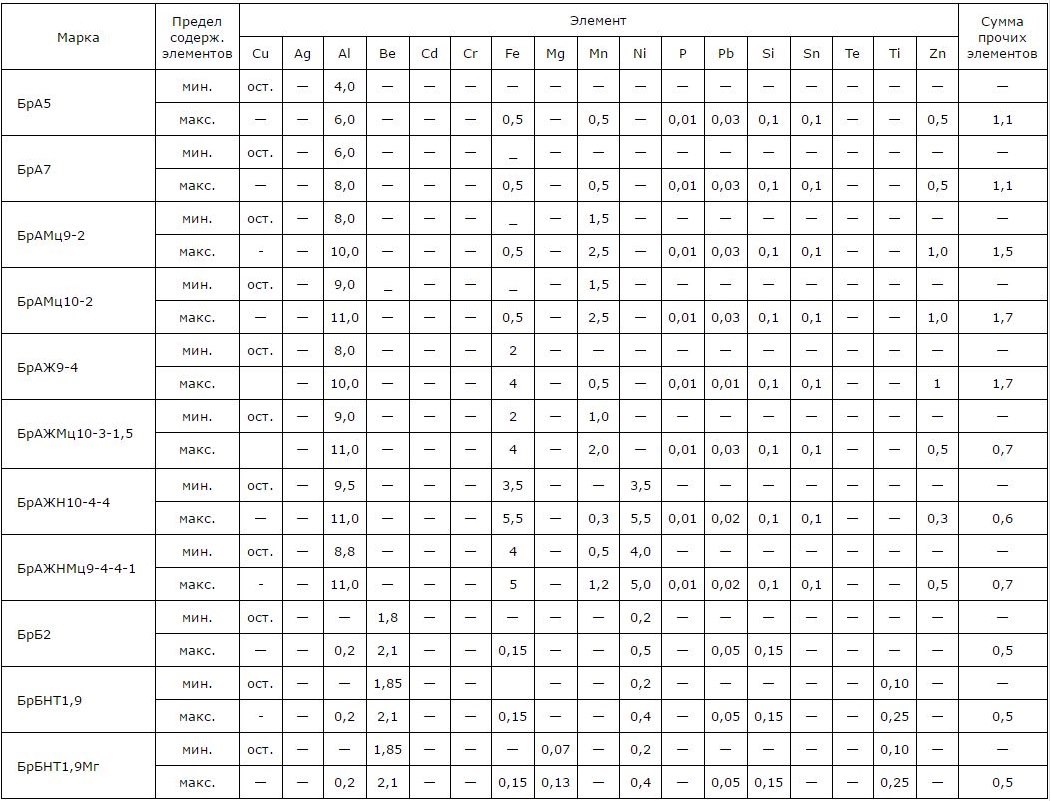

Chemical composition of tin-free bronzes (click to enlarge)

Thermal conductivity and other characteristics of bronze

As mentioned above, the percentage of the main alloying element in the chemical composition of bronze changes not only the color, but also mechanical properties. The density and specific gravity, if you compare them with similar characteristics of materials of other brands, change slightly. This pattern is relevant not only for bronze, but also for brass, as well as for other copper alloys.

If we talk about tin bronzes, then this is their property, as plasticity, begins to decline in that case, if the percentage of tin in them exceeds 5%. If the tin content is brought to 20%, then simultaneously with the decrease in hardness will increase the fragility of such material. That is why only bronze can be used to perform foundry operations and metal processing by plastic deformation, which contains no more 6% tin.

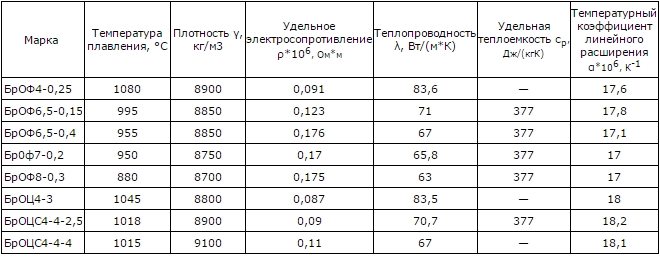

Physical properties of tin bronzes

Zinc is added to the chemical composition of some brands of bronze, the content of which can reach 10%. This alloying does not change the specific gravity and density of the metal, and does not have a significant effect on its mechanical properties, but reduces its cost.

To improve this property of bronze, as machinability by cutting (in particular, facilitate the process of breaking chips), a small amount of lead is injected into it (to 5%). Phosphorus, present in some brands of bronze, which are called phosphorous, acts in them as an deoxidizer.

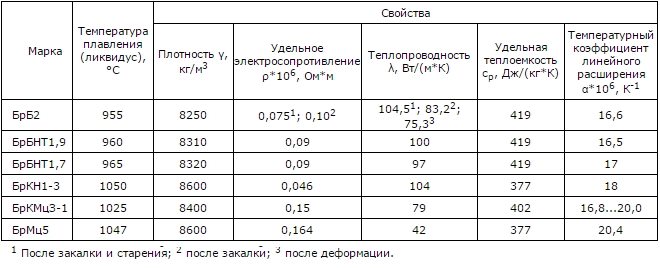

Physical properties of siliceous, beryllium and manganese bronze

An important property of bronze, which contains tin, there is a minimum shrinkage factor. In most other characteristics, tin-free bronzes are superior to tin ones. So, alloys, the main alloying element in which is aluminum, differ in the improved mechanical properties, as well as more resistant to even very aggressive environments. Alloys, in which copper is mixed with silicon and zinc, have a high fluidity in the molten state, which determined the scope of their application - the manufacture of various items by casting. Beryllium-containing bronzes are strong and solid materials, products from which also differ in high elasticity.

Physical characteristics of aluminum bronzes

When mixing copper with alloying additives, which occurs when creating bronze, this property of the base metal is reduced, as thermal conductivity. In particular, those chemical elements, used in the manufacture of bronze, make its thermal conductivity even lower, than in another copper alloy - brass. The only exceptions are those brands of bronze, in which the copper content is very significant.

This is a property of most brands of bronze, as low thermal conductivity, somewhat limits the scope of their application. Because of that, that they do not dissipate heat very well, products from them are not used in heavily loaded friction units, such bronzes are not used to make welding electrodes, as well as elements of mechanisms, which must provide prompt heat dissipation.

Areas of application and labeling rules

The variety of applications of bronze is due to its unique properties. The modern range of its brands allows you to optimally select them to solve certain technological problems.

Areas of application of tin bronzes

Gear elements are made of bronze alloys of various brands, screw and worm connections, details, subject to significant friction during operation, electrical and plumbing products, different membranes, springs, fasteners. in addition, bronze parts of various equipment are made of bronze, it is used in shipbuilding and the automotive industry and even in the aerospace industry. Interior compositions have long been made of bronze, sculptures, now it is also used in the manufacture of furniture fittings, plumbing and various decorative items.

Areas of application of tin-free foundry bronzes

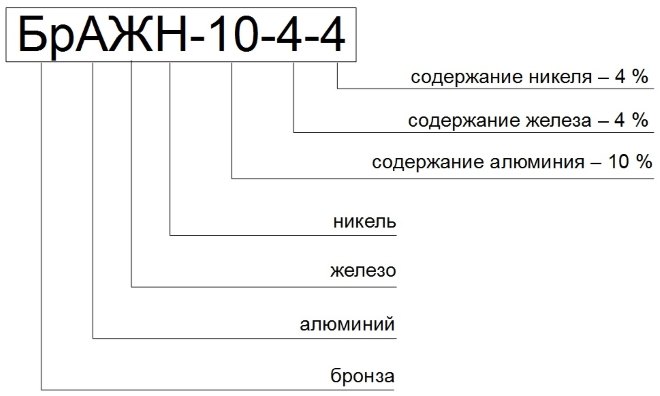

Only very experienced professionals are able to identify even a photo of a bronze product, what brand of alloy it is made of. And marking helps non-professionals to solve such a problem, consisting of alphanumeric notation. It always contains the letters "K", which indicates, that in front of you is bronze. in addition, there are other letters in the label, each of which denotes a chemical element, which is part of the bronze alloy. The percentage of copper in the label is not specified, it can be determined, if subtracted from 100% (the entire volume of bronze) the total number of other elements.

Example of marking a bronze alloy

Marking of a bronze alloy, in addition to details of its chemical composition, allows you to determine the basic properties, which he owns. To such properties, in particular, include the density of the material, as well as its share. This information is of purely practical importance. Knowing the specific gravity, which has a certain bronze alloy, you can easily calculate the exact weight of the object, which is made of it.

All such information, as well as the exact chemical composition of bronze of various brands, contained in special tables.