Hardening of stainless steel at home: video, instruction

Though, what is a technological procedure, as hardening of stainless steel products, leads to a decrease in their plasticity and flexibility, the use of this method of heat treatment allows them to give exceptional hardness. Modern hardening technologies and their correct selection ensure high quality steel, in which the proportions of strength are optimally maintained, plasticity and viscosity. The performance of such products is significantly improved.

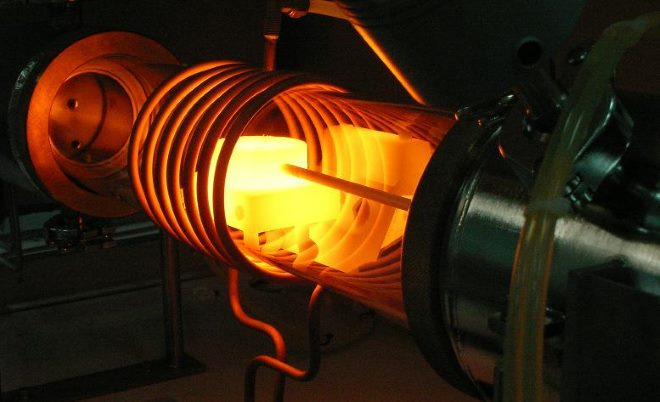

Hardening steel in the induction duct installation

Features and purpose of steel hardening

Such technology, as hardening steel, actively used by mankind for quite some time. Even in the Middle Ages, this method of heat treatment was used to improve the strength and hardness of cold steel, as well as tools, used in agriculture. The question is, how to harden stainless steel, arose then, when people learned to produce steel alloys on an industrial scale, possessing exceptional anticorrosive properties. It was during this period that new technologies for hardening steel were developed, allowing to create materials with outstanding physical and chemical characteristics.

Hardening procedures are mainly exposed to stainless steel, which differ in martensitic internal structure. A characteristic feature of such stainless steel alloys is that, that in the normal state they have increased hardness and tendency to embrittlement. If products from such steels are subjected to heat treatment, which involves the implementation of a quick vacation, then you can increase the viscosity, which significantly expands the scope of their application.

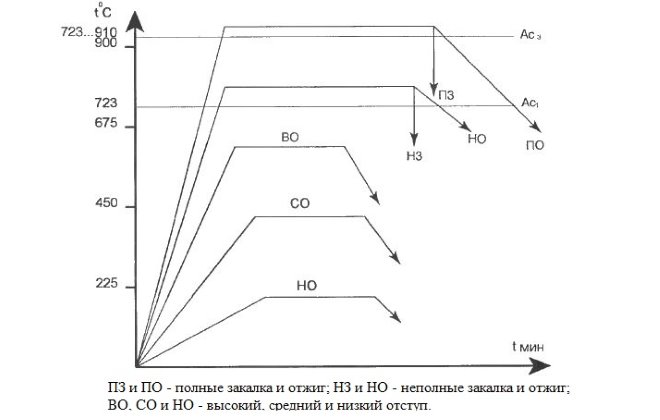

Changing the mode of heat treatment of steel allows to obtain different physical and mechanical properties of the metal

Depending on the product hardening tasks to be solved, made of stainless steel, can perform one of two ways - with heating:

- the whole product (global hardening);

- only that part of the product, which must be hardened (local hardening).

It is necessary to approach very seriously and to a choice of a way of cooling hardens details after its heating.

It should be borne in mind, that for different brands of stainless steel methods of cooling products, hardened or tempered, can be very different.

If ordinary water is often used as a cooling medium when heat-treating low-alloy steels, then the following substances are used for cooling stainless steel alloys, like butter, saline and alkaline solutions.

Choice of temperature mode

The most important task, which should be resolved, starting to harden the product, made of stainless steel, - this is the right choice of temperature. If the stainless steel product overheats during hardening, then you can face it, that it will lose its original strength, due to a decrease in the amount of carbon in its internal structure.

Modes of heat treatment of chromium steels and the obtained mechanical properties

Very often when hardening stainless steels they have residual stresses, which can be removed by further machining (rental, etc.). Such problems can be avoided at the stage of heat treatment, if to carry out cooling of the hardened details in several stages, with a gradual decrease in temperature on each of them. This method of cooling is often used in those cases, when as a result of hardening it is necessary to receive a product, which is particularly high strength.

The essence of the method of gradual cooling of the hardened product, made of stainless steel, is, that after heating it is successively lowered into the bath, containing various cooling media: salt solutions, meadows, mineral or synthetic oils. The most significant advantage of this technique is, that when it is used in the structure of the metal, all internal stresses are completely eliminated, which have a negative impact on its quality. The disadvantages of this method include the high cost of its implementation, which limits the scope of its application.

Recommendations for hardening stainless steel at home

If there is a need to improve the performance and increase the hardness of the stainless steel product, then you can harden it at home, after reading the practical recommendations and studying this process on video. As an example, we can consider in detail the hardening of the stainless steel blade.

To make a stainless steel knife harder and stronger at home, the following materials and equipment will be required:

- electric stove or gas burner;

- wiper;

- common turpentine.

Homemade gas horn

The very technique of hardening a stainless steel knife, presented in many videos on the Internet, is the following sequence of actions.

- The metal part of the knife (without handle) placed in a chamber of an unheated electric furnace.

- Turning on the oven, it is necessary to heat the knife to the state, when it turns bright red (950-10500). If you do not have an electric oven, then the knife can be heated with a gas burner or hot coals, but then it will be difficult to achieve uniform heating of the metal.

- After a short exposure at a given temperature (5-10 minutes) than remove from the oven and immerse its blade in wax on 1 give me a sec. The procedure of immersion and removal should be repeated until then, until you feel it, that the knife is included in this material with some difficulty (as in butter).

- Completion of the procedure of hardening the knife at home is to clean it from wax residues and wipe the blade with a cloth, soaked in turpentine.

Carrying out self-hardening of a knife from stainless steel, the following should be borne in mind: overheating of the metal can lead to this, that knife blade, becoming too hard, will lose its elasticity, and this will impair its cutting properties.