Countersink and countersink on metal - the essence of the processes of countersinking and countersinking

In the process of production of high quality parts and products often have to deal with insufficient accuracy of the required holes. To obtain the necessary parameters use a countersink.

Countersink d35

Application and types of countersinks

The countersink is multi-blade, multi-toothed cutting tool, used for finishing pre-made round holes in parts and blanks of different materials (in the photo). Processing in this way is used to increase the diameter and obtain a better surface of the hole by cutting.

This process is called countersinking. The cutting method is similar to the drilling procedure: the same rotation of countersinking equipment around its axis and simultaneous translational movement of the tool along the axis is observed.

Countersink with carbide plates

Developed a countersink for the metalworking industry for drilling, perforated or made by stamping holes. Countersink on metal, requirements for the characteristics of which are regulated by GOST 12489-71, used when performing intermediate or already final processing. In this regard, there are two types of tools:

- for further deployment with allowance;

- to obtain high-precision holes - with quality H11 (admittance 4-5 accuracy class).

You can get acquainted with the requirements of GOST to Zenker, by downloading the document in pdf format at the link below.

GUEST 12489-71 Countersinks are integral. Design and dimensions

download

When using boring, the diameter increases, surface accuracy and hole cleanliness increase. Countersinking is intended mainly for:

- achieve a smoother, clean surface holes before the procedure of unfolding or threading;

- calibration of the bolt hole, hairpin or any other fastener.

Countersinks are used, requirements to which are determined by GOST 12489-71, also when processing end surfaces and when performing some operations, which give the hole the desired profile (example, widening the recess at the top of the hole, intended for bolt heads).

Countersinks are divided into several types according to the method of fixing them in the machine:

- mounted;

- tail (with metric cone or with Morse taper - types of shank for mounting in the machine).

diamond countersink

By design, countersinks are of the following types:

- national teams;

- integral;

- welded;

- with carbide plates.

A solid countersink looks like a drill, therefore, its second name is a countersink drill. He has more, than a simple drill, spiral grooves and cutting edges (from 3 to 6 teeth). The cutting part of the tool, as determined by GOST 12489-71, made of high-speed steel P18, P9 or do with carbide inserts (BK4, BK6, BK8 for processing of pig-iron, T15K6 - for steel processing). Tool, equipped with carbide plates, has high performance (higher cutting speed), than is made of high-speed steel.

There is also a conical countersink (for surface treatment of conical configuration) and the so-called reverse type of countersink.

Spiral tail countersinks

Countersinking and related operations

Countersinking is similar to a drilling operation: both processes are carried out with a ready hole. The difference is, that the result of countersinking is more accurate. In the course of operation shortcomings are eliminated, arising after stamping, casting or drilling. The following indicators are improving, as surface cleanliness, precision, a high degree of coaxiality is achieved.

Often when forming holes with a drill (especially deep) there is a deviation from the center due to the low rigidity of the tool. The countersink differs from the drill, which has a higher rigidity due to the increased number of cutting teeth. Importantly, that such a difference provides a more precise direction of movement of the tool, and at smaller depth of cutting high purity is observed. When drilling holes, you can get quality 11-12, the surface roughness of the hole Rz 20 micrometers. During the countersinking operation we get qualities 9-11, roughness 2,5 micrometers.

Deploy conical under the Morse taper

An even more accurate operation is the deployment process (6-9-and quality, R a 1,25 0,25 micrometers). This is a finishing touch. Countersinking holes is a semi-clean operation. Countersinking and deployment of holes, if both of these operations are provided by the technological process, are performed in one installation of parts on the machine.

Often confuse countersinking and countersinking holes and incorrectly call the countersink another tool - countersinking (div. Photo below). Zenkovki, unlike countersinks, have a different design and are used to solve other technological problems.

countersinks conical

Countersinking is used in the process of removing the chamfer from the top of the holes, and to obtain conical recesses. Sometimes the countersink is cylindrical, but it is more correct to call such a tool Tsekovka. By means of such tool in details deepenings of the corresponding form receive. To perform such countersinking operations can also be used a universal tool - a drill, specially combined with countersink.

After watching this video, you can easily understand the principle of operation and purpose of the countersink, as well as its difference from the countersink and other related tools for processing holes.

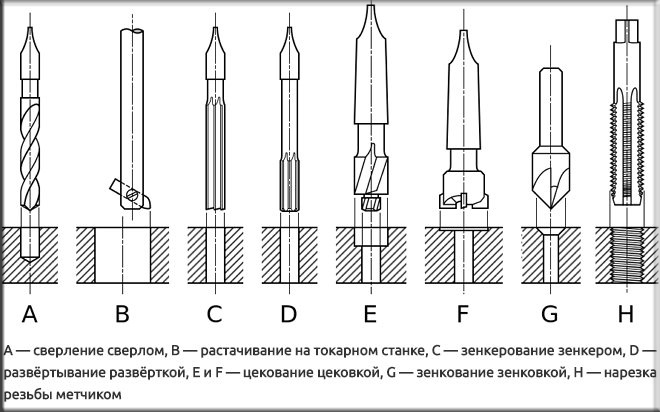

Not to be confused in similar operations, it is enough to consider and remember this scheme, clearly explains the design differences and the purpose of tools for machining holes

Metal countersinking rules

At home for countersinking recesses (example, under bolt heads or to change the diameter of the hole to the larger side) a simple drill will do, fixed in an electric or even a hand drill. On a production scale, countersinking is an operation, which requires considerable power and accuracy of the equipment used. That is why in terms of production to countersink, as, actually, and countersinks, use equipment:

- turner (most often);

- drilling (not less often);

- boring (quite often, as one of the secondary operations);

- aggregate (as a secondary operation of the automated line);

- vertical or horizontal milling (rarely).

In the process of processing the hole, obtained in the product during its casting, it is desirable to first grind it with a cutter about 5-10 millimeters in depth for that, that the countersink took the correct initial direction.

When processing steel products, it is recommended to use lubricants and coolants. The process of countersinking cast iron and non-ferrous metals does not require cooling. Proper selection of metal cutting tools, used for countersinking, and for countersinking, - a very important stage. To do this, pay attention to certain factors:

- The type of tool is selected depending on the material of the part, the nature of the processing. The location of the hole must also be taken into account, seriality of executed processes.

- Based on the specified depth, diameter, the required processing accuracy, select the size of the tool for countersinking and countersinking.

- The design of the countersink and countersink is determined by the method of mounting the tool on the machine.

- The material of the tool for performing countersinking or countersinking operations depends on the material of the workpiece (example, there are countersinks specifically for wood work), the intensity of the mode of operation and some other factors.

Countersinking on a vertical CNC drilling machine

The countersink is chosen according to directories or guided by such normative document, as GOST 12489-71. The tool must meet certain technical conditions of use, which also determines GOST 12489-71.

- Ware, made of structural steel, with holes to 40 millimeters in diameter are processed by a countersink, made of high-speed steel, having a diameter, respectively 10-40 millimeters and 3-4 tooth.

- For products from hard-worked and hardened steels at boring apply equipment with hard-alloy plates in diameter 14-50 millimeters and has 3-4 tooth.

- In structural steel products holes to 80 millimeters in diameter bored with a countersink of high-speed steel, using mounting heads with a diameter 32-80 millimeters.

- In products from non-ferrous metals and pig-iron for boring of blind apertures apply a feather countersink.

- Blind holes in diameter 15-25 millimeters are treated with a special tool for countersinking, in the case of which there is a channel, on which the lubricating and cooling liquid in a cutting zone moves.

A necessary condition for countersinking is compliance with allowances. The diameter of the selected tool as a result should coincide with the final diameter of the hole after machining. When after countersinking it is planned to deploy holes, the diameter of the tool is reduced by 0,15-0,3 millimeters. If rough boring or drilling under countersinking is planned, it is necessary to leave the allowance on the side of the value of 0,5 to 2 millimeters.

Countersinking is a much more productive process, than cutting. The cutting speed for a high-speed steel countersink is close to the drilling process, and filing - above c 2,5-3 times. That is why the countersinking process is faster, than the drilling process.