Welding of stainless steel semiautomatic in the environment of carbon dioxide: video, instruction

Semi-automatic stainless steel welding can be quite difficult not only for beginners, but also for an experienced specialist. Such difficulties are primarily due to the characteristics of the metal itself, for high-quality welding it is necessary to choose the right operating modes of welding and the corresponding consumables.

Semi-automatic machine for welding metal in a protective gas environment

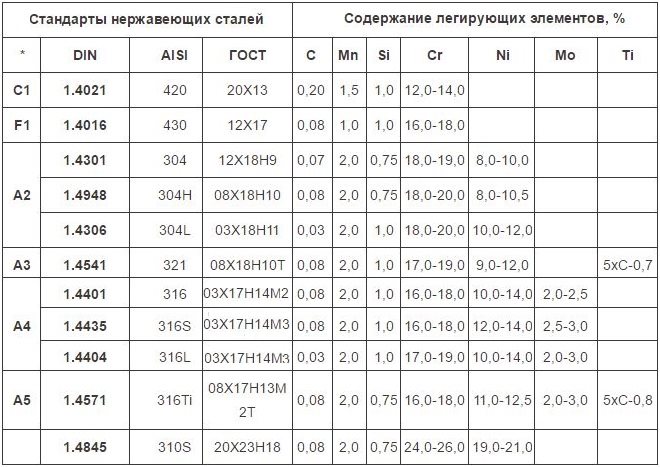

Types of stainless steels

The main alloying element of steels, belonging to the category of stainless steel, is chrome. Thanks to this element, which stainless steel must contain at least 12%, an oxide film is created on its surface. Despite the very small thickness of this film, sometimes does not exceed the size of several atoms, it provides reliable protection of metal against corrosion. in addition, if this protective film is accidentally or intentionally damaged by mechanical impact, then after a while it will restore its integrity.

In the chemical composition of the vast majority of stainless steel brands, except iron, carbon and chromium, may contain the following chemical elements, like nickel, titanium, niobium and molybdenum. These elements, which are a part of a stainless steel in rather insignificant quantities, improve as anticorrosive, and mechanical properties of the alloy.

Chemical composition of the main brands of stainless steel

Stainless steels, depending on the characteristics of its internal structure may belong to one of the following types.

martensitic

These are alloys, containing in its composition 17% chromium and 0,5% carbon. Stainless steel with this structure has a hardness and high fragility and can be successfully operated only in mildly aggressive environments.

austenitic

In the chemical composition of such steels, except chromium and carbon, also contains nickel, which increases the austenitic region in their structure. Excellent qualities of such alloys, belonging to the category of nonmagnetic, has high corrosion resistance, strength, optimally combined with good plasticity.

ferrite

These include stainless steel alloys, containing no more 0,12% carbon and to 30% chromium. Taka stainless steel, characterized by a good ratio of high strength and ductility, resistant to thermal hardening and can be successfully operated under aggressive environments.

Welding of stainless steel in the protective environment by the semiautomatic device provides high-quality connection of products

Properties and weldability of stainless steel

Become, belonging to the category of stainless steel, is a difficult to weld material, due to a number of their physical and chemical characteristics. Deciding to cook stainless steel semi-automatically, you need to consider a number of important parameters. Only in this case you can count on it, that the resulting welded joint will be of the required quality and reliability.

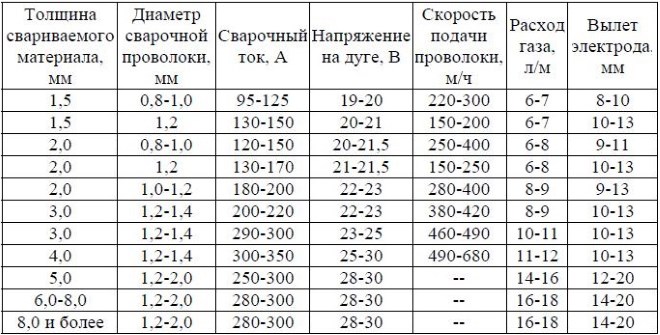

Compared with steels of other categories, stainless is quite low (on average twice) thermal conductivity. Due to this, the heat from the welding zone is very poorly removed, as a result, the metal is subject to significant overheating, which negatively affects its corrosion resistance. To avoid such negative consequences, welding of stainless steel with the help of a semi-automatic machine is performed at low current (on 15-20%), and the connecting parts are subjected to additional cooling.

Approximate modes of semi-automatic welding in a protective gas environment

At considerable heating (over 500 °) carbide compounds are formed at the boundaries of the stainless steel crystal lattice, which are the cause of this phenomenon, as intergranular corrosion. As a result, the internal structure of the metal stratifies and corrosion processes develop. To avoid this, resort to more intensive cooling of the connected products, for which ordinary water can be used.

Boil stainless steel (including in the environment of shielding gas) difficult also because, that it has a tendency to thermal expansion. Significant expansion of connected products, which occurs in the process of semi-automatic welding, leads to the formation of cracks as in the weld, and mostly metal. In the meantime, this can be avoided, if a wider gap is left between the welded parts.

High-quality welded stainless steel seam may be slightly gray, but not dark

Stainless steel due to its chemical composition has a fairly high electrical resistance, which causes significant heating of the electrodes, used to perform semi-automatic welding. Therefore, electrodes are used to weld stainless steel, made of wire with a certain chemical composition, and the length of the rods, if they contain chromium and nickel, should not exceed 350 mm.

Supplies

Good results in the connection of stainless steel parts can be achieved by welding, performed in a protective gas environment. To cook with this technology, naturally, will be required as special equipment, and related consumables, which are filler wire and the gas itself.

The purpose of the gas in semi-automatic welding is to protect the molten metal in the welding bath from oxidation. Gas, which is used for such protection, it must not react with the molten metal, so as not to adversely affect it. That is why inert argon is mainly used as a protective medium, mixed with a small amount of carbon dioxide.

Welded seam on the left, made in the environment of carbon dioxide. On the right - in argon (98%)

Standard composition of the gas mixture, used in the welding of stainless steel semi-automatic, includes 98% argon and 2% carbon dioxide. In some cases, to reduce the cost of welding, it is allowed to use a gas mixture, consisting of 70% argon and 30% carbon dioxide.

To cook stainless steel, while receiving a high-quality and reliable weld, it is very important to choose the right filler wire, which must also be made ??stainless steel. In those cases, when it is not possible to use shielding gas, semi-automatic welding is carried out in a normal environment, but for its performance use a special flux-cored wire. Meanwhile, the use of the latter leads to that, that welds may eventually become covered with a layer of rust.

Some features of the technology

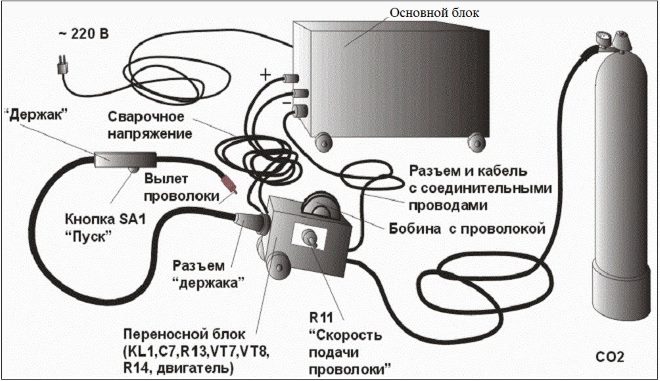

Significantly improve the quality of stainless steel welding, as well as simplify the process of its implementation allows the use of special semi-automatic welding machines, mentioned above. The use of such equipment allows you to solve several technological problems, which include:

- supply of filler wire to the area of formation of the connection;

- supply of shielding gas to the welding zone;

- cooling of the welding torch;

- ensuring the convenience of welded joints in hard-to-reach places.

Equipment for semiautomatic welding

Significant internal stresses are formed in stainless steel products during welding, which are removed by their subsequent heat treatment - heating to temperature 660-760 ° and slow cooling outdoors.

Preparation for welding

Before cooking with a semi-automatic product, made of stainless steel, they must be properly prepared, to get a quality and reliable connection. The process of such preparation is as follows.

- Surface details, the connecting ones are carefully cleaned with the use of a metal brush, and then degreased, for which you can use the most common solvents.

- To remove residual moisture from the surface of the product, it is heated to temperature 100 °.

Preparation of stainless steel for collector welding

Rules and methods of welding

As mentioned above, to cook stainless steel with the help of a semi-automatic machine, you need to choose the right filler wire, from which the weld will be formed. Optimally, if the degree of alloying of the wire exceeds the same parameter of the base metal. This is due to the fact, that alloying elements, contained in the chemical composition of the wire, will burn out of the metal during its melting, therefore, their content should be taken into account in reserve.

For semi-automatic welding of stainless steel wire with ultra-low carbon content and high silicon content is used, resistant to oxidizing media

For welding products, made of stainless steel, three main methods are used:

- short arc method (applied in those cases, when welding products of small thickness);

- jet transfer method (allows to carry out welding of details even of very considerable thickness);

- pulse (the most universal technology, that allows to carry out welding works with high productivity and at the same time to save the spent resources).

Each of these methods has certain features, but there are general rules, which should be followed, using each of them. Consider these rules.

- The burner housing is located at the opposite angle to the seam, to provide a quality overview of the latter.

- Burner nozzle, through which protective gas and a welding wire are given, have a distance of approximately 12 mm from the surface of the products.

- Additive wire, molten ??as a result of burning an electric arc, is fed into the area of the formed weld in small drops.

Burner position - approx 11 year

in addition, there are general recommendations for welding, for the implementation of which shielding gas is used.

- Stainless steel should be cooked only in the opposite polarity.

- Angle, under which the nozzle of the welding machine is located, should provide a good welded joint and a small width of the molded seam.

- The departure of the wire from the nozzle of the welding machine should not exceed 12 mm.

- Gas consumption, which forms a protective environment, should be in the interval 6-12 m3 / min.

- Gas, which is fed into the welding zone, must be pre-passed through the dehumidifier, as which copper vitriol is used.

- To minimize splashing of molten metal from the welding area, the surface of the joined products is treated with an aqueous solution of chalk.

- To get a good and quality weld, it should not start and end at the very edge of the details, connecting. It is better to retreat some distance. Welding itself, which is important, is performed without oscillating movements away from the molded seam.

Elimination of deformations

Stainless steel products can be deformed during welding, due to their significant heating during this procedure. In order to correct such defects, you can use one of two methods.

- Using a hammer and trowel, formed on the surface of stainless steel "bubble" just knock, moving from the edge of the part.

- Correcting the distortion formed by tapping will be more effective, if you combine it with heating parts, for which you can use an ordinary gas burner.

In order to cook stainless steel with the help of a semi-automatic machine, it is not enough just to get acquainted with the theoretical basis, It is very desirable to watch a training video on this topic.